Junior Assembler Resume

Objective : A knowledgeable Junior Assembler who understands installation and repair processes, how they are carried out and methods to increase efficiency. Looking for opportunities that offer training and growth in maintenance, repair, and processes. Excels at building effective teams that succeed in any work environment. Looking for a position in the manufacturing industry that will allow me to utilize my skills and experience as a machine operator or in production.

Skills : Operating Forklifts, Computer Sales And Purchasing, Answering Phones, Phone Sales, Lifting, Driving, Typing, Customer Service, Sales, Automotive Parts And Function

Description :

- Assembled automotive parts for production and quality check, observed machine operation to detect workpiece defects or machine malfunctions, adjusting machines as necessary.

- Set up and operated machines, such as lathes, cutters, shears, borers, millers, grinders, presses, drills, and auxiliary machines, to make metallic and plastic workpieces.

- Inspected workpieces for defects, and measured the workpieces to determine the accuracy of machine operation, using rules, templates, or other measuring instruments.

- Determined product specifications and tooling instructions and to plan operational sequences.

- Started machines and turned handwheels or valves to engage feeding, cooling, and lubricating mechanisms.

- Selected, installed, and adjusted the alignment of drills, cutters, dies, guides, and holding devices using templates, measuring instruments, and hand tools.

- Moved controls or mount gears, cams, or templates in machines to set feed rates and cutting speeds, depths, and angles.

- Positioned, adjusted, and secured stock material or workpieces against stops, on arbors, or in chunks, fixtures, or automatic feeding mechanisms, manually or using hoists.

- Set machine stops or guides to specified lengths as indicated by scales, rules, or templates.

Experience

2-5 Years

Level

Junior

Education

Vocational in Economics

Assembler/Production Resume

Objective : Assembler/production experienced in manufacturing work, proficient in the use of multiple hand tools, both production and assembly experienced forklift driver, both sit-down and standup configurations.To secure a position that utilizes my skills, abilities, experience and positive work habits to achieve the goals of the company.

Skills : Electric Pallet Jack, Loading, Unloading, Packaging Product, Problem Solver, Embrace Challenges, Dependable, Conscientious, Works Well As A Team/Crew Member

Description :

- Studied assembly instructions, blueprint specifications, and parts lists to assemble a large variety of Modine-manufactured air units by gathering parts, subassemblies, tools, and materials.

- Tools included rivet gun, awl, ratchets, wrenches, pliers, and wire stripper cutters.

- Positioned parts and subassemblies by using templates or reading measurements.

- Assembled, constructed, and installed actuator motors, blowers, damper blades, linkages, wiring - all built from the ground up, by examining connections for correct fit, fastening parts, and subassemblies.

- Resolved assembly problems by altering dimensions to meet specifications, notified the supervisor when additional resources or tools were required.

- Kept equipment operational by completing preventive maintenance requirements, followed Modine manufacturing company techniques and instructions to troubleshoot malfunctions, called for or brought to the attention of the supervisor any need for repairs.

- Maintained supplies inventory by checking stock to determine inventory level, anticipated needed supplies, placed and expedited orders for supplies, verified receipt of supplies.

- Conserved resources by using company equipment and supplies efficiently in order to accomplish assembly of quality heating and cooling air units.

- Performed other duties as assigned, maintaining a safe and clean working environment that complied with company procedures, rules, and regulations.

Experience

2-5 Years

Level

Junior

Education

Diploma in General

Assembler/Imprinter Resume

Objective : Resilient Assembler/Imprinter, successful at handling the rigorous physical demands of operating heavy duty machinery for extended periods of time. A team player and a team leader. Experienced in several areas including assembly, customer service, and medical billing and filing. To become gainfully employed utilizing my knowledge in computers, electronics, machine operations, and repair.

Skills : Forklift, Overhead Cranes, Multi-meters, Calipers, Depth Gauges, Scales, Computers Hardware, And Software, Saws, Drills, Measuring Tapes

Description :

- Preparing work to be accomplished by studying assembly instructions, blueprint specifications, and parts lists, gathering parts, subassemblies, tools, and materials.

- Positioning parts and subassemblies by using templates or reading measurements.

- Assembling components by examining connections for correct fit, fastening parts, and subassemblies.

- Resolving assembly problems by altering dimensions to meet specifications; notifying supervisor to obtain additional resources.

- Keeping equipment operational by completing preventive maintenance requirements, following manufacturer's instructions, troubleshooting malfunctions, calling for repairs.

- Maintaining a safe and clean working environment by complying with procedures, rules, and regulations.

- Maintaining supplies inventory by checking stock to determine inventory level, anticipating needed supplies, placing and expediting orders for supplies, verifying receipt of supplies.

- Conserving resources by using equipment and supplies as needed to accomplish job results.

Experience

2-5 Years

Level

Junior

Education

Associates

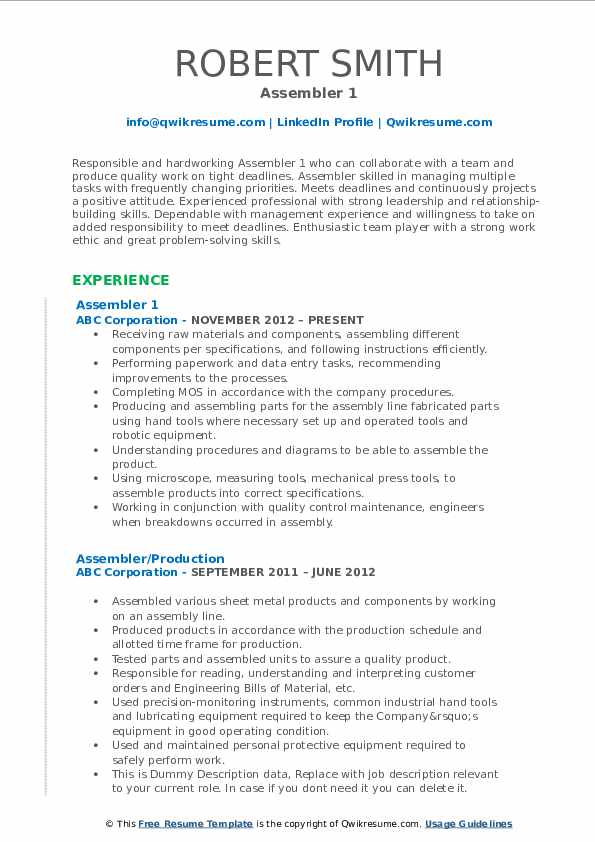

Assembler 1 Resume

Summary : Responsible and hardworking Assembler 1 who can collaborate with a team and produce quality work on tight deadlines. Assembler skilled in managing multiple tasks with frequently changing priorities. Meets deadlines and continuously projects a positive attitude. Experienced professional with strong leadership and relationship-building skills. Dependable with management experience and willingness to take on added responsibility to meet deadlines. Enthusiastic team player with a strong work ethic and great problem-solving skills.

Skills : Wiring Diagrams, Mechanical Drawings Blue Prints, Punches, Micrometers, Grinders, Pallet Jack, Scissor Lifts, Brake Press, Inspections

Description :

- Receiving raw materials and components, assembling different components per specifications, and following instructions efficiently.

- Performing paperwork and data entry tasks, recommending improvements to the processes.

- Completing MOS in accordance with the company procedures.

- Producing and assembling parts for the assembly line fabricated parts using hand tools where necessary set up and operated tools and robotic equipment.

- Understanding procedures and diagrams to be able to assemble the product.

- Using microscope, measuring tools, mechanical press tools, to assemble products into correct specifications.

- Working in conjunction with quality control maintenance, engineers when breakdowns occurred in assembly.

- Preparing work to be accomplished by studying assembly instructions, and parts lists, gathering parts, tools, and materials.

Experience

7-10 Years

Level

Senior

Education

Management

Machine Operator/Assembler Resume

Summary : Skilled and committed Machine Operator/Assembler aimed at improving performance through innovative management techniques. Possesses a high degree of integrity and an outstanding work ethic as well as the ability to work well even when under pressure. Most interested in quality and health field related kind of work. Seeking suitable full-time employment that will utilize my work experience of 18 years and knowledge that will assist an organization to be as successful and profitable as possible.

Skills : Customer Service, Phones, Computer Proficient, Microsoft Office, Soldering, Wire Testing, Packaging, Maintenance, Assembly

Description :

- Positioned and secured various components on a pallet of chain conveyor for assembly.

- Unpacked parts from boxes. Stocked parts to machine. Packed parts and/or finished assemblies in preparation for shipping.

- Inspected assemblies for defects by operating specialized test equipment and visual checking. Marked defects appropriately.

- Monitored and adjusted automated machine settings to produce quality parts in accordance with model specifications.

- Performed basic math calculations to maintain accurate counts of parts produced, parts inventoried, or to determine program modifications.

- Performed daily machine start-up and shutdown procedures.

- Maintained line-side inventory of parts. Operated hand tools to inspect for defects, correct repairable defects and machine troubleshoot minor malfunctions.

- Performed minor tooling changes and changeovers. Read and followed written instructions and basic mechanical drawings.

Experience

10+ Years

Level

Consultant

Education

GED in Technical Certificate

Line Assembler Resume

Objective : Line Assembler skilled in managing multiple tasks with frequently changing priorities. Meets deadlines and continuously projects a positive attitude. Also, good with fast-paced assembly lines Hard worker can put my mind to anything good with hands-on training quick learner adapt to learning skills and processes.

Skills : Forklift, Packaging, Maintenance, Assembly, Customer Service, Welding, Power Tools

Description :

- Set-up and operates drill presses, crimpers, and blockers.

- Performed basic set-ups and set-up changes on label and nameplate machines and operates same after set-up.

- Provided relief for the assembly line, trained assembly line operators and checked the quality of work.

- Verified quantities against packing lists and packed the various product and parts in cartons, bags, pans, and containers. Applied labels and stencils as assigned.

- Visually and/or dimensionally checked materials, supplies, parts, sub-assemblies and finished product for shortages, defects, and non-standard conditions.

- Upon discovery notified supervision of all shortages, defects, non-standard conditions and malfunctioning machinery and equipment.

- Maintained related records, cleaned the machinery, equipment, and work area on a daily basis and performed preventative maintenance as assigned.

- Moved materials as required using hand or power equipment. Performed all related miscellaneous duties as directed by supervision

Experience

0-2 Years

Level

Entry Level

Education

High School Diploma

Senior Assembler Resume

Summary : Resourceful, goal-oriented, personable, hard-working, motivated, proactive Senior Assembler with extensive experience of 9 plus years in the mechanical background, teamwork and organization. Strengths include organizing, motivating people and a strong work ethic. Track record of being responsible, having a positive attitude, problem-solving, attentive, job completion in a timely and organized manner, and being strong remodel for co-workers and community. To obtain a position within a company that will allow me to utilize experience in the customer service and light industrial industries.

Skills : Microsoft Office, Forklift Operator, Lab Work, Packaging, Inventory, Panel Assembly And Wiring, Mechanical And Electrical Drawing Interpretation, Mechanically Inclined

Description :

- Assembling components by examining connections for correct fit, fastening parts, and subassemblies.

- Maintaining a safe and clean working environment by complying with procedures, rules, and regulations.

- Conserving resources by using equipment and supplies as needed to accomplish job results.

- Documenting actions by completing production and quality forms and contributes to team effort by accomplishing related results as needed.

- Recording test results on standardized forms and writing test reports describing procedures used.

- Testing a sample of manufactured products to verify conformity to specifications.

- Recording scraps transactions due to assembly problems.

- Making suggestions to supervisors for improvements associated with assigned work.

- Maintaining a clean and orderly work area per the company policy.

Experience

7-10 Years

Level

Senior

Education

Diploma

Assembler Resume

Summary : Manufacturing Assembler having 9 years of experience, including as an Assemble.Effective at completing difficult projects and tasks on schedule. Consistently follows through with all orders and instructions. Works well in a team setting.A position in a manufacturing environment utilizing my skills in team building, training, expediting, and inventory control.

Skills : Packing, Picking, Shipping, Receiving, Processing, Data Entry, Repair, Handheld Tools, And Team Lead Duties

Description :

- Maintaining a safe and clean working environment while assembling lawn mower parts by complying with procedures, rules, and regulations.

- Resolving assembly problems by altering dimensions to meet specifications, notifying the supervisor to obtain additional resources.

- Recording inspection and test data, including weights and quantities, inspected.

- Inspecting and deburring the incoming production parts.

- Assisting in labeling and packaging, preparing shipper cartons.

- Using manual and electric pallet jack and forklift as needed.

- Assisting in others' areas as needed and performing other duties as assigned.

- Ensuring the shipping area is organized and clean at all times and meets all compliance factors.

- Pulling and prepping raw material for specific jobs.

Experience

7-10 Years

Level

Senior

Education

Certificate

General Assembler Resume

Objective : Dependable General Assembler experienced in manufacturing production, assembly, quality assurance, and machine operation and maintenance. Deadline-driven Machine Operator with 3+ years of experience in a fast-paced environment.Expert in mechanical assembly knowledge of metal parts and assemblies certified heavy equipment operator drilling machine experience

Skills : Time Management, Communication, Team Player, Team Player, Organizational, Self-Motivated, Self-Starter, Machine Operation, Operations, Installation

Description :

- Received and correctly processed both written and verbal instructions, prints and work orders.

- Recognized and reported defective material and equipment to shift supervisor.

- Aligned motor, air end and coupling using calipers, dial indicators, and straight edges.

- Planned and paced work efficiently in order to meet daily, weekly, project or production goals.

- Correctly and safely used a variety of hand tools, saws and cutting equipment to carry out job duties.

- Cleaned containers, materials, and work areas with cleaning solutions and tools.

- Marked labels, measuring, weigh up, and counting products and materials.

- Adhered to workmanship standards, safety policies and requirements forklift and Skyjack.

- Resolved assembly problems by altering dimensions to meet specifications, notifying supervisor to obtain additional resources.

Experience

2-5 Years

Level

Junior

Education

Business Management

Production Assembler Resume

Summary : Production Assembler more than 15 years of professional stockroom/warehousing experience, with exemplary leadership qualities and professional customer service appeal. Extensive background in customer-oriented service operations. Excellent communication skills maintain positive relations with staff and customers in high-volume, fast-paced operating atmospheres.

Skills : Inspection, Manufacturing, Clerical, Plumbing, Carpentry, Assembly, Mechanical, And Some Electrical Residential And Automotive

Description :

- Installed assemblies, such as flashing, pipes, tubes, heating, and air conditioning ducts, furnace casings, rain gutters, and downspouts, in supportive frameworks.

- Selected gauges and types of sheet metal or non-metallic material, according to product specifications.

- Fastened seams and joints together with welds, bolts, cement, rivets, solder, caulks, metal drive clips, and bonds in order to assemble components into products or to repair sheet metal items.

- Fabricated or altered parts using shears, hammers, punches, and drills.

- Maintained a safe and cleaned the working environment by complying with procedures, rules, and regulations.

- Resolved assembly problems by altering dimensions to meet specifications; notifying supervisor to obtain additional resources.

- Assembled components by examining connections for correct fit, fastening parts, and subassemblies.

- Demonstrated accuracy in the assembly of units/components requiring adept soldering skills.

Experience

10+ Years

Level

Consultant

Education

High School Diploma

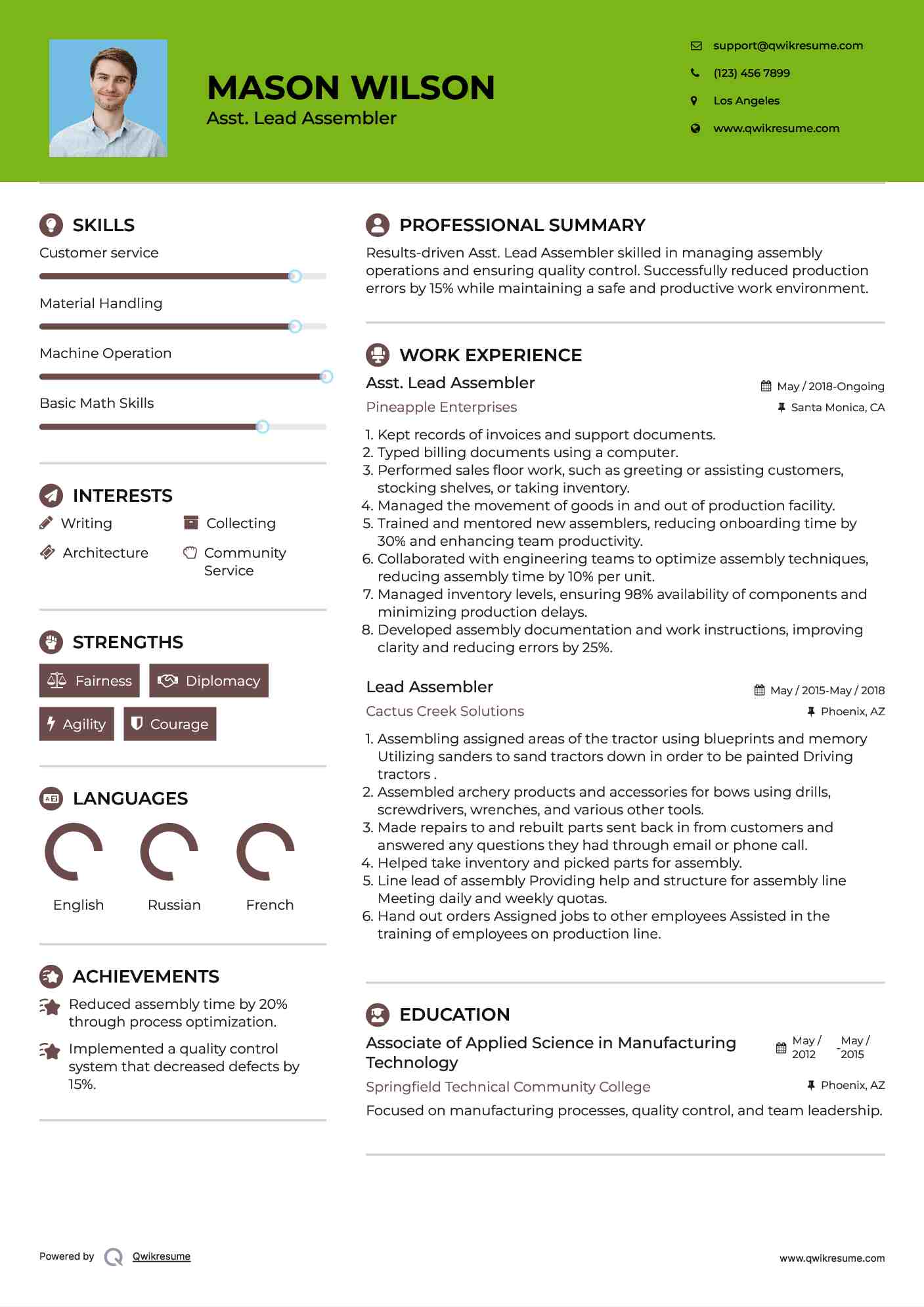

Asst. Lead Assembler Resume

Summary : A career opportunity that will allow use of experience and skills in the best interest of the company that seek employment with.

Skills : Effectively communicate both oral and written, Customer service.

Description :

- Operated compressors, striping machines, sandblasters and spray equipment.

- Completed and updated all work orders, records of service calls and work logs.

- Prepared itemized invoices and record amounts due for items purchased or services rendered.

- Kept records of invoices and support documents.

- Typed billing documents using a computer.

- Performed sales floor work, such as greeting or assisting customers, stocking shelves, or taking inventory.

- Managed the movement of goods in and out of production facility.

Experience

10+ Years

Level

Senior

Education

High School Diploma

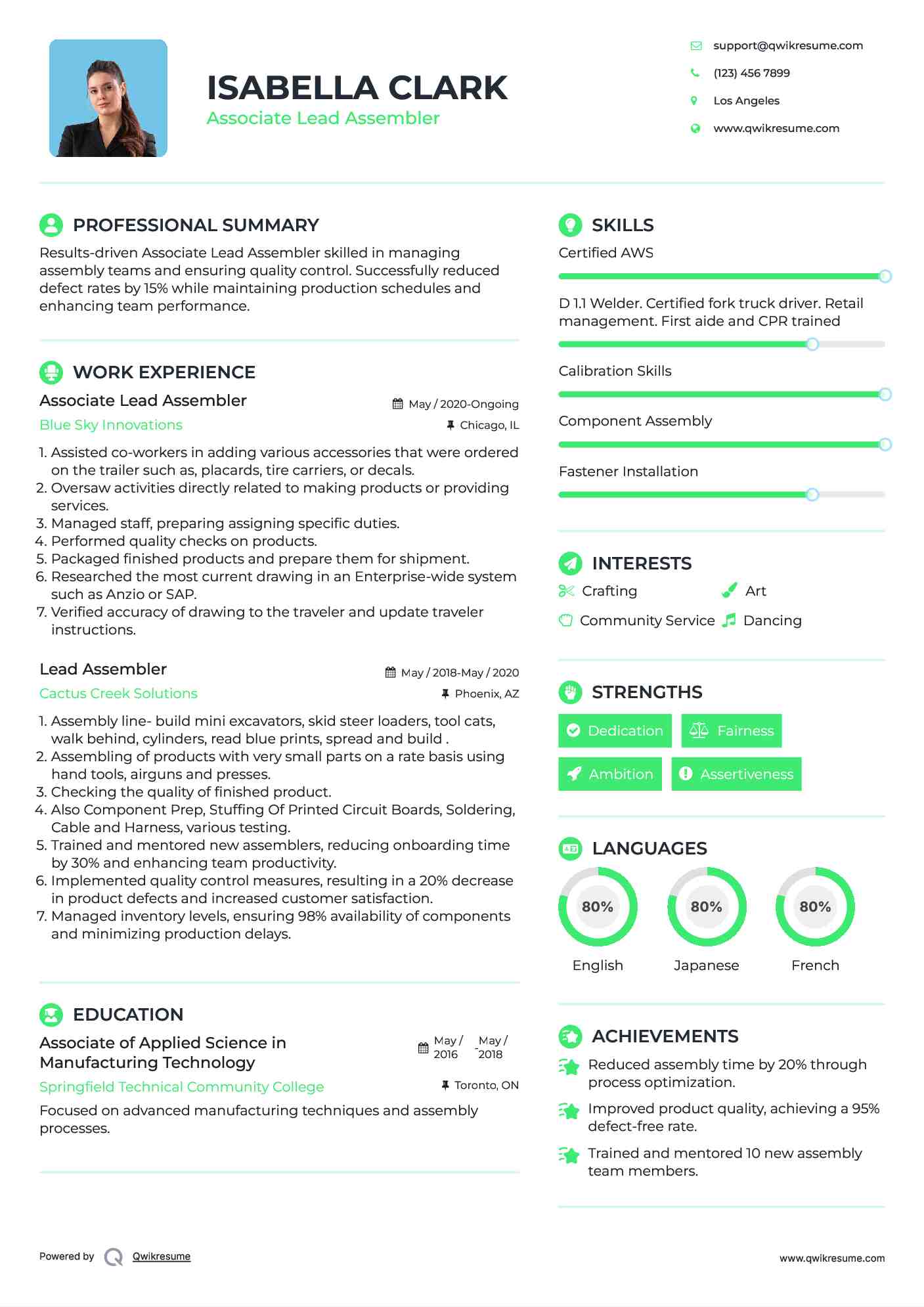

Associate Lead Assembler Resume

Headline : To achieve a challenging position within a dynamic team of professionals that leverages experience while providing opportunities to expand capabilities and knowledge.

Skills : Certified AWS, D 1.1 Welder. Certified fork truck driver. Retail management. First aide and CPR trained.

Description :

- Assisted co-workers in adding various accessories that were ordered on the trailer such as, placards, tire carriers, or decals.

- Oversaw activities directly related to making products or providing services.

- Managed staff, preparing assigning specific duties.

- Performed quality checks on products.

- Packaged finished products and prepare them for shipment.

- Researched the most current drawing in an Enterprise-wide system such as Anzio or SAP.

- Verified accuracy of drawing to the traveler and update traveler instructions.

Experience

5-7 Years

Level

Executive

Education

Forest Tech

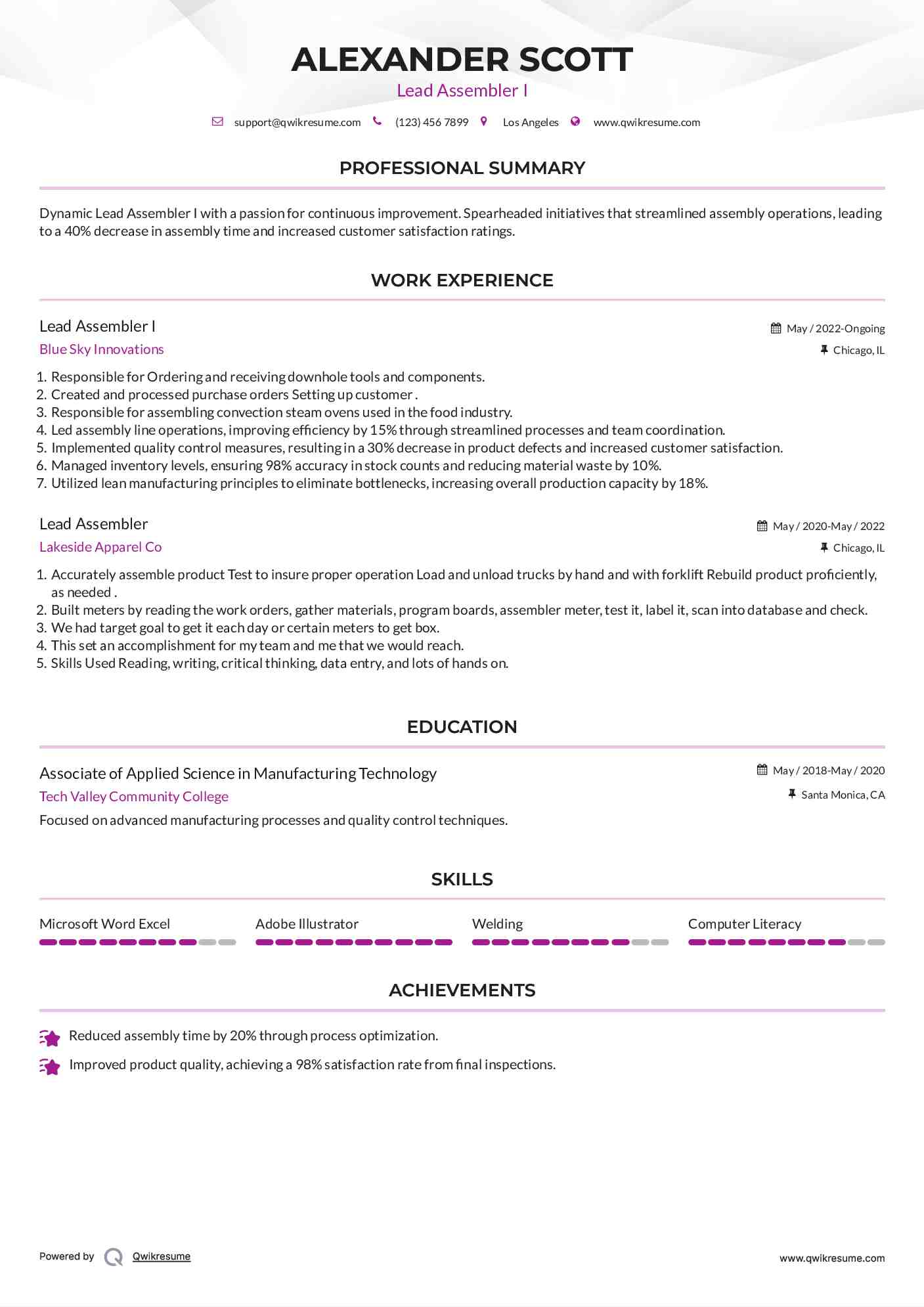

Lead Assembler I Resume

Objective : Seeking to secure a permanent position with a reputable company where can continue to develop and enhance skills and knowledge and use past training to help others.

Skills : Microsoft Word Excel, Adobe Illustrator, Welding.

Description :

- Responsible for Ordering and receiving downhole tools and components.

- Created and processed purchase orders Setting up customer .

- Assembled complete Subsea 6th Gen BOP Stack from bare frame, with continuation on Test Team FAT to final shipping of the BOP Stack.

- Assembled complete Subsea 6th Gen BOP Stack from bare frame, on Test Team to do FAT to finished product.

- Assembled complete Subsea 6th Gen BOP Stack from bare frame, on Test Team to do FAT to finished product.

- Assembled the entire pump from bare frame up, achieved Lead Technician role over the MLP delivery and accomplished.

- Responsible for assembling convection steam ovens used in the food industry.

Experience

2-5 Years

Level

Junior

Education

GED

Lead Assembler Resume

Summary : Detail-oriented Assembler adept at interpreting blueprints, working with others, and meeting production deadlines. Skilled at quickly learning new processes and technologies. Self-motivated with strong organizational and time management abilities.

Skills : Forklift, operator, lead assembler or Team Leader.

Description :

- Supervised assemblers and train employees on job procedures.

- Managed the daily scheduled production, cover for team members that were absent and maintain efficiency rates.

- Processed all non-conforming materials within the department.

- Ensured inventory levels were accurate and reduced loss of production by 98%.

- Met on time deliveries 95% to 100% of the time, providing resources were available.

- Assisted with the reorganization of the Table Top Steamer assembly line.

- Doubled unit production from 12 to 24 each day.

Experience

10+ Years

Level

Senior

Education

High School Diploma

Assistant Senior Assembler I Resume

Summary : A position utilizing experience while expanding base of knowledge and permitting advancement congruent with growing abilities. High School diploma or GED equivalent. Strong verbal and written communication skills. Proficient at interpreting drawings, diagrams, part lists, inspection standards, revision control, reference documents and work instructions.

Skills : Metal Fabricating, Robotic Welding, Welding.

Description :

- Motorized and free rolling conveyor rollers.

- Assembled rollers with semi-automated machinery.

- Assembled specialized rollers manually.

- Tested rollers on test bench.

- Packaged rollers for shipment.

- Improved process by creating fixtures for manual assembly processes.

- Suggested and implemented inventory control methods.

Experience

7-10 Years

Level

Management

Education

Mechanical Engineering

Senior Assembler Resume

Objective : Offering several years of experience in manufacturing using IPC -610 standards. QCing of first article inspection of slide line, and post wave products. Ability to use the AOI, microscope, soldering iron and wave solder machines. Knowledge of reading customer documentation.

Skills : Aircraft Maintenance, Industrial Maintenance, Automotive Technician.

Description :

- Responsible for performing a variety of tasks including repetitive to non-repetitive production assembly operations on electronic and mechanical assemblies and subassemblies such as modules, boards, panels, drawers, frames, bonding, and cables.

- Made continuity checks on work in process and completed work.

- Worked directly from diagrams and drawings, make initial layouts, and use hand and power tools, jigs, and saws to perform tasks.

- Conducted quality inspections on processing line in accordance with quality specifications.

- Accepted new assignments and responsibilities with a positive, cooperative, and team-oriented attitude and assist management by helping to ensure compliance with all health and safety policies, procedures, and protocols.

- Implemented effective solutions to problems, use various tools to complete projects, ensure consistency in quality of work performed, and regularly review and inspect results to achieve the high standards.

Experience

0-2 Years

Level

Junior

Education

Education

Product Assembler/Supervisor Resume

Summary : A position where there is continuous growth. Also one that requires skills needed to exceed goals and maintain customer and employee relations.

Skills : Organized, Communication Skills.

Description :

- Assembled kid's battery operated ride-on, baby furniture, and almost all Big Ticket items that were displayed in the store.

- Helped guests in the bicycle department as needed, and did storeroom work as well.

- Proper adjustment of brakes and gears on a bicycle of any size or make.

- Assembled them from memory. Skills Used Knowledge of product being assembled.

- Created a safety hazard for the user.

- Demonstrated product knowledge within the scope of their job family detail.

- Ensured that all production deadlines are met.

Experience

7-10 Years

Level

Management

Education

Business

Lead Product Assembler Resume

Headline : Dependable and accomplished bringing management experience and a willingness to take on added responsibility in order to meet tight deadlines. Strong work ethic and advanced complex problem solving skills.

Skills : Exceptional Interpersonal Communication, Effective Leadership, Efficient Multitasker.

Description :

- Efficiently performed all Learner level job functions. Operated designated assembly/packaging equipment.

- Performed job functions independently or with minimal assistance from the trainer.

- Assembled components into complete or partial products according to standard work.

- Demonstrated capability of routine/minor set-up on basic equipment.

- Verified trace id information of all materials used for each job.

- Understood and followed proper part handling procedures.

- Recognized non-conformances and informed supervisor, team coordinator, or set-up.

Experience

5-7 Years

Level

Executive

Education

Business

Product Assembler Resume

Summary : Community Based Residential Facility Certified CPR Certified, First Aide trained Able to perform medication administration and provide appropriate documentation.

Skills : Technical Skills, Management.

Description :

- Assembled metal products, such as vacuum cleaners, valves, and hydraulic cylinders.

- Executed daily operations of installed springs.

- Positioned parts according to the knowledge of the unit being assembled.

- Fastened parts together with bolts, screws, speed clips, rivets, and other fasteners.

- Used hand tools and portable powered tools.

- Trained and managed over 100 heaters and achieved significant improvements in their productivity.

- Removed small quantities of metal with hand files and scrapers.

Experience

7-10 Years

Level

Management

Education

C.B.R.F