Chemical Engineering Intern Resume

Objective : Aspiring Chemical Engineering Intern with 2 years of hands-on experience in wastewater analysis and process optimization. Proficient in data collection and statistical analysis, I am eager to leverage my skills in a dynamic engineering environment. My strong analytical abilities and commitment to safety standards will contribute positively to project outcomes.

Skills : Data Analysis, Process Optimization, Process Design, Thermodynamics

Description :

- Analyzed wastewater samples to determine nickel content and recommend treatment solutions.

- Utilized Microsoft Excel for data organization and analysis, ensuring accuracy in reporting.

- Coordinated transportation of test samples to external labs for comprehensive analysis.

- Developed hypotheses and conducted experiments to optimize chemical treatment processes.

- Managed inventory for materials and supplies, ensuring efficient lab operations.

- Processed contractor orders through online systems to streamline supply chain activities.

- Executed sensor calibration procedures to monitor chemical levels in pools and spas.

Experience

0-2 Years

Level

Entry Level

Education

B.S. Chem Eng.

Chemical Engineering Trainee Resume

Objective : Motivated Chemical Engineering professional with 2 years of practical experience in process optimization and chemical analysis. Adept at utilizing data-driven approaches to enhance operational efficiency and ensure compliance with safety standards. I aim to apply my analytical skills and innovative mindset to contribute to impactful engineering projects.

Skills : Data Analysis Software, Laboratory Techniques, Statistical Analysis, Computer-aided Design, Unit Operations

Description :

- Calculated and prescribed chemical dosage for customer pools by analyzing chemical data, maintaining optimal chemical levels.

- Conducted material compatibility research to determine appropriate construction materials for microfluidic chips.

- Performed quality assurance on Beta products by executing longevity and repeatability tests.

- Reduced cleaning time by 66.67% through root cause analysis and troubleshooting calibration procedures.

- Improved mixing efficiency in Beta products by recommending and implementing design changes.

- Established consistent flow rates for microfluidic cartridges by optimizing diaphragm pump testing protocols.

- Designed experiments to ascertain permissible volume errors for accurate chemical testing.

Experience

0-2 Years

Level

Entry Level

Education

B.S. Ch.E.

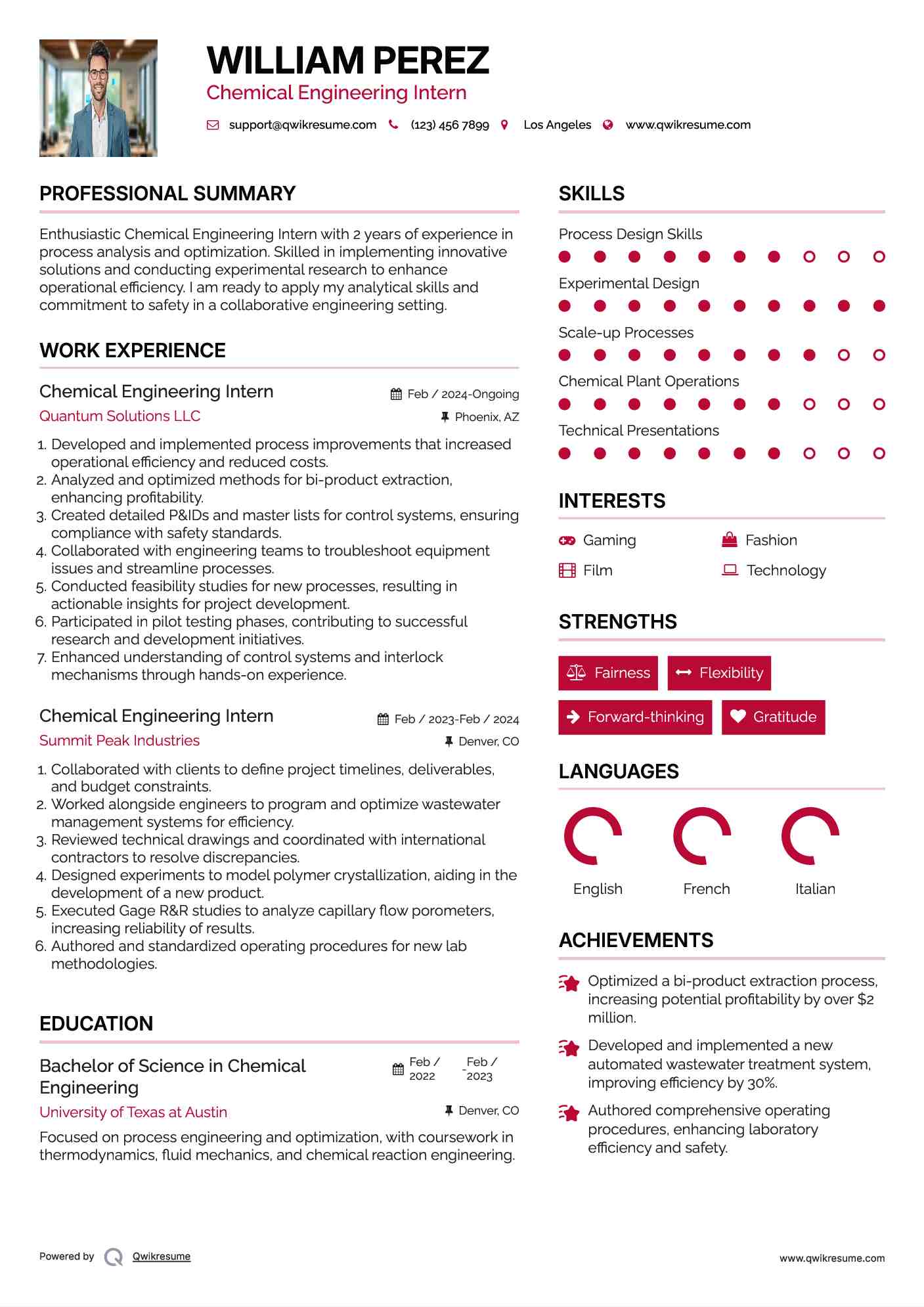

Chemical Engineering Intern Resume

Objective : Enthusiastic Chemical Engineering Intern with 2 years of experience in process analysis and optimization. Skilled in implementing innovative solutions and conducting experimental research to enhance operational efficiency. I am ready to apply my analytical skills and commitment to safety in a collaborative engineering setting.

Skills : Process Design Skills, Experimental Design, Scale-up Processes, Chemical Plant Operations, Technical Presentations

Description :

- Developed and implemented process improvements that increased operational efficiency and reduced costs.

- Analyzed and optimized methods for bi-product extraction, enhancing profitability.

- Created detailed P&IDs and master lists for control systems, ensuring compliance with safety standards.

- Collaborated with engineering teams to troubleshoot equipment issues and streamline processes.

- Conducted feasibility studies for new processes, resulting in actionable insights for project development.

- Participated in pilot testing phases, contributing to successful research and development initiatives.

- Enhanced understanding of control systems and interlock mechanisms through hands-on experience.

Experience

0-2 Years

Level

Entry Level

Education

B.S. Ch.E.

Chemical Process Intern Resume

Objective : Driven Chemical Process Intern with 2 years of experience in process optimization and data analysis. My background in innovative solutions and project management equips me to enhance operational effectiveness in dynamic environments. I am committed to applying my technical skills and analytical mindset to contribute to successful engineering projects.

Skills : Statistical Analysis Software, Quality Control, Chemical Reaction Engineering, Separation Processes, Material Science

Description :

- Identified and quantified reserves of copper, gold, and molybdenum across multiple international sites.

- Conducted thorough research on competitor patents in biomining to inform project strategies.

- Proposed and developed a new bioprocess to enhance copper production efficiency.

- Designed analytical plans to evaluate the impact of potential contaminants in production.

- Analyzed project data to assess recycling viability and sustainability.

- Successfully defended a new biomining proposal, demonstrating its advantages over traditional methods.

- Negotiated partnerships with research entities, minimizing financial commitments while maximizing project potential.

Experience

0-2 Years

Level

Entry Level

Education

B.S. in Chem Eng.

Chemical Engineering Intern Resume

Objective : Passionate Chemical Engineering Intern with two years of experience in process analysis and optimization. Adept at applying data-driven methodologies to enhance system efficiencies and ensure regulatory compliance. My technical skills and proactive approach will drive impactful contributions in a collaborative engineering environment.

Skills : Chemical Process Simulation, Team Collaboration, Cross-functional Collaboration, Process Flow Diagrams, Technical Writing

Description :

- Conducted engineering analysis to optimize chemical processes, resulting in enhanced efficiency.

- Utilized analytical skills to troubleshoot and resolve process-related issues.

- Collaborated with teams to review and improve facility procedures and protocols.

- Provided technical support for data collection and analysis for key projects.

- Participated in project engineering modifications and design processes.

- Assisted in the documentation and reporting of project outcomes.

- Engaged in safety audits and compliance checks to ensure adherence to industry standards.

Experience

0-2 Years

Level

Entry Level

Education

B.S. Chem. Eng.

Chemical Engineering Assistant Resume

Objective : Dedicated Chemical Engineering Assistant with 2 years of experience in process optimization and chemical analysis. Skilled in leveraging data analytics to drive efficiency and enhance safety protocols. Eager to apply my technical expertise and problem-solving abilities to support innovative engineering projects and contribute to successful outcomes.

Skills : Lean Six Sigma Methodologies, Process Troubleshooting, Process Simulation, Analytical Chemistry

Description :

- Designed experiments to assess chemical levels in various pool depths, optimizing product dimensions.

- Shadowed management during land acquisitions and operational projects to gain insights into industry practices.

- Collaborated with the General Manager on facility construction projects, enhancing operational capabilities.

- Monitored production lines, ensuring equipment performance and adherence to quality standards.

- Utilized Lean techniques, Statistical Process Control, and DMAIC to enhance project execution.

- Assisted in the design and optimization of chemical processes for production efficiency.

- Gained hands-on experience with safety protocols in an industrial setting.

Experience

0-2 Years

Level

Entry Level

Education

B.S. Chem. Eng.

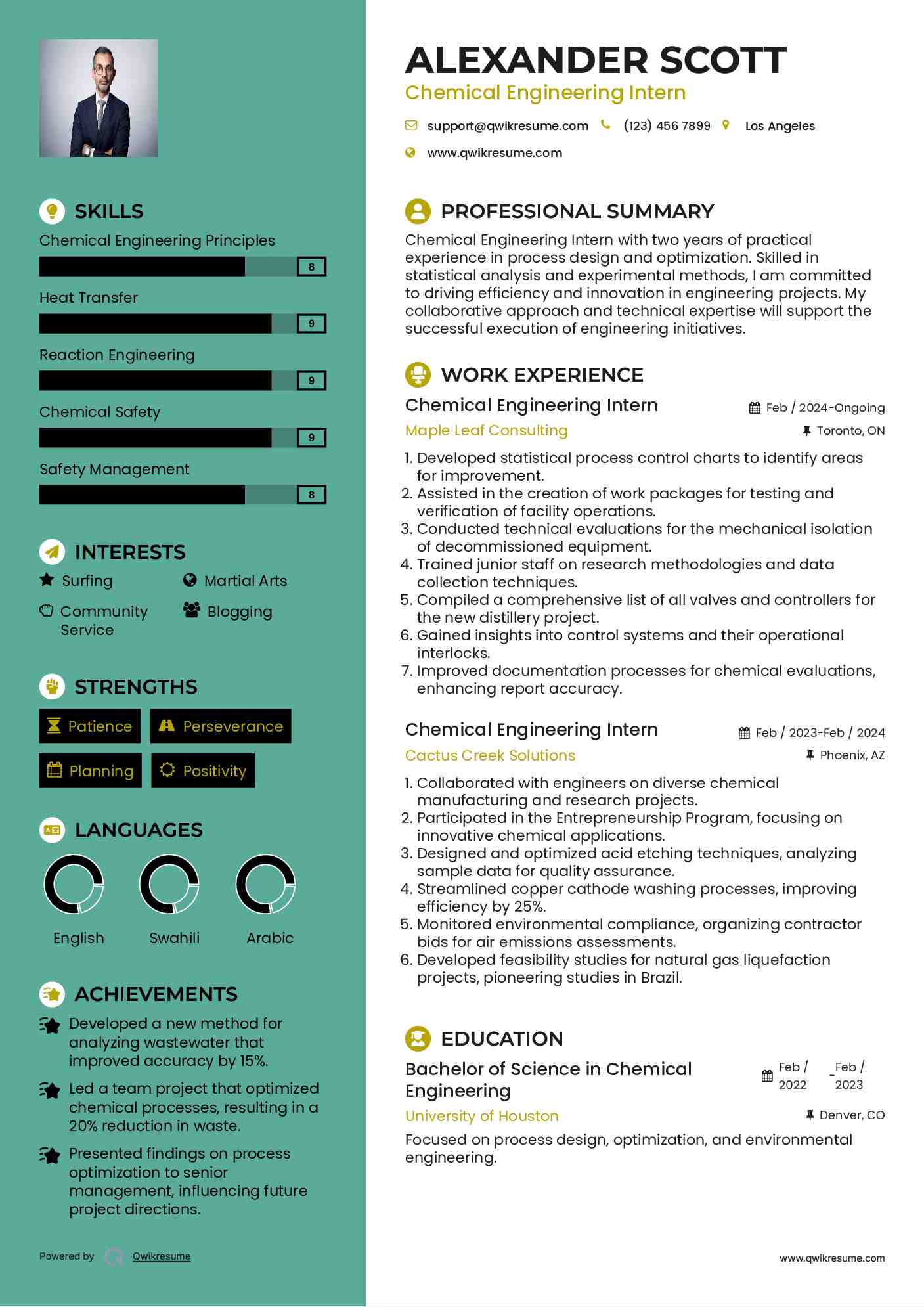

Chemical Engineering Intern Resume

Objective : Chemical Engineering Intern with two years of practical experience in process design and optimization. Skilled in statistical analysis and experimental methods, I am committed to driving efficiency and innovation in engineering projects. My collaborative approach and technical expertise will support the successful execution of engineering initiatives.

Skills : Chemical Engineering Principles, Heat Transfer, Reaction Engineering, Chemical Safety, Safety Management

Description :

- Developed statistical process control charts to identify areas for improvement.

- Assisted in the creation of work packages for testing and verification of facility operations.

- Conducted technical evaluations for the mechanical isolation of decommissioned equipment.

- Trained junior staff on research methodologies and data collection techniques.

- Compiled a comprehensive list of all valves and controllers for the new distillery project.

- Gained insights into control systems and their operational interlocks.

- Improved documentation processes for chemical evaluations, enhancing report accuracy.

Experience

0-2 Years

Level

Entry Level

Education

B.S. Chem. Eng.

Chemical Technician Intern Resume

Objective : With two years of hands-on experience in chemical process analysis and optimization, I excel in conducting experiments and ensuring safety compliance. My expertise in data collection and environmental assessments empowers me to contribute effectively to innovative projects. I am eager to apply my strong analytical skills in a collaborative environment to achieve exceptional results.

Skills : Process Improvement Techniques, Electrochemistry, Industrial Chemistry, Simulation Software, Chemical Reaction Design

Description :

- Conducted safety audits to ensure compliance with industry regulations.

- Enhanced efficiency of solvent extraction processes through optimization techniques.

- Authored and revised standard operating procedures to improve operational quality.

- Collected and analyzed water and soil samples for environmental assessments.

- Performed assays on water samples to monitor quality control.

- Trained and assessed operators on equipment handling and safety measures.

- Developed testing methodologies to recover organic solvents effectively.

Experience

0-2 Years

Level

Entry Level

Education

B.S. Chemistry

Chemical Engineering Intern Resume

Objective : Ambitious Chemical Engineering Intern with two years of experience in process optimization and chemical analysis. I possess a strong foundation in data analytics and experimental design, eager to apply my skills in a fast-paced engineering setting. My commitment to safety and efficiency will drive successful project outcomes while supporting innovative solutions.

Skills : Chemical Process Design, Project Coordination, Chemical Kinetics, Safety Protocols, Environmental Engineering

Description :

- Collaborated on interdisciplinary projects with Process and Mechanical Engineering teams for clients including Cross Oil and DCP Midstream.

- Contributed to a comprehensive technical presentation on the Dehydration of Natural and Sour Gas Treating.

- Participated in team meetings to discuss project progress and challenges.

- Facilitated communication between project engineers and vendors to obtain preliminary equipment quotes.

- Gained hands-on experience with process equipment and troubleshooting methodologies.

- Prepared technical reports and presentations for project findings.

- Achieved proficiency in Aspen Process Explorer for process simulation and analysis.

Experience

0-2 Years

Level

Entry Level

Education

B.S. ChE

Chemical Engineering Intern Resume

Objective : Chemical Engineering Intern with two years of diverse experience in process optimization and chemical treatment. Skilled in designing innovative solutions and conducting rigorous data analysis to improve operational efficiency. I am enthusiastic about applying my analytical expertise and commitment to safety in a collaborative engineering environment, driving impactful results on projects.

Skills : Project Management, Regulatory Compliance, Instrumentation, Cost Analysis, Sustainability Practices

Description :

- Analyzed wellbore failures to identify root causes and implemented effective solutions.

- Designed and executed a chemical treatment program that significantly mitigated operational issues.

- Facilitated weekly performance meetings with field operators to optimize chemical treatment processes.

- Redesigned artificial lift systems using improved materials, increasing fluid production rates.

- Developed a unique fracturing sand mixture to prevent paraffin formation during well completion.

- Achieved a reduction in operational costs from $700,000 to $5,000 per month through process enhancements.

- Collaborated with cross-functional teams to improve project economics and efficiency.

Experience

0-2 Years

Level

Entry Level

Education

B.S. Ch.E.