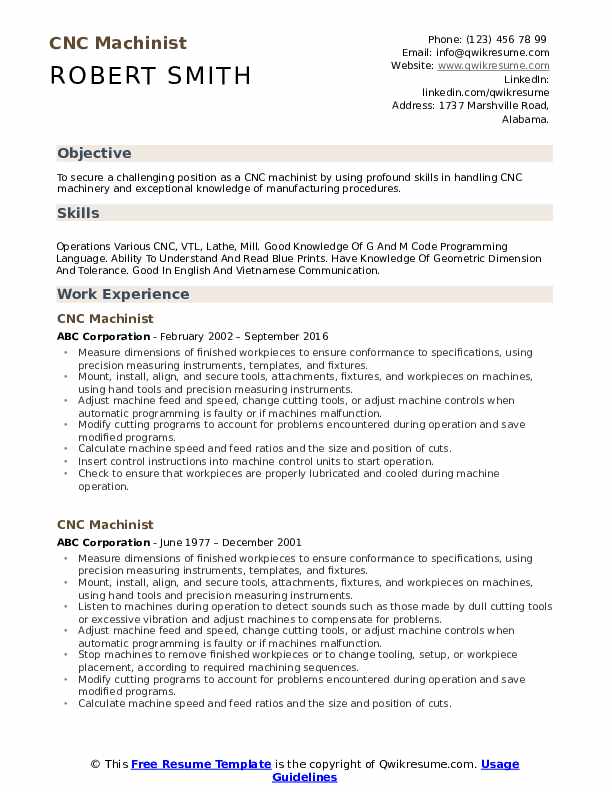

CNC Machinist Resume

Objective : Dedicated CNC Machinist with 2 years of hands-on experience in precision machining and programming. Proficient in operating CNC mills and lathes, ensuring high-quality production standards. Committed to continuous improvement and teamwork in a fast-paced manufacturing environment.

Skills : Cnc Operations, Vertical Turning Lathe (vtl), Cnc Programming, G-code Proficiency

Description :

- Set up and operated CNC machines to produce precision components according to specifications.

- Adjusted machine settings based on material specifications and production requirements.

- Conducted regular quality checks using precision measuring instruments to ensure adherence to tolerances.

- Collaborated with engineering teams to optimize machining processes and troubleshoot issues.

- Maintained a clean and organized workspace, adhering to safety and quality standards.

- Documented production data and machine performance for continuous improvement analysis.

- Participated in team meetings to discuss production goals and strategies.

Experience

0-2 Years

Level

Entry Level

Education

AAS-CNC

Junior CNC Machinist Resume

Objective : Proficient Junior CNC Machinist with 5 years of extensive experience in precision machining and programming. Adept at operating CNC mills and lathes, maintaining rigorous quality standards while optimizing production efficiency. Passionate about enhancing processes and collaborating within teams to achieve manufacturing excellence.

Skills : Material Selection, Quality Assurance, Tool Calibration, Workholding Methods, Machinery Maintenance

Description :

- Calculate machine speed and feed ratios to optimize cutting precision.

- Ensure proper lubrication and cooling of workpieces during operations.

- Input commands into machine controllers to execute programmed instructions.

- Inspect electronic components for defects using precision measuring tools.

- Modify machine programs and specifications using computer software.

- Initiate operations by inserting control instructions into machines.

- Conduct quality checks and inspections throughout the production process.

Experience

2-5 Years

Level

Junior

Education

AAS in CNC Tech

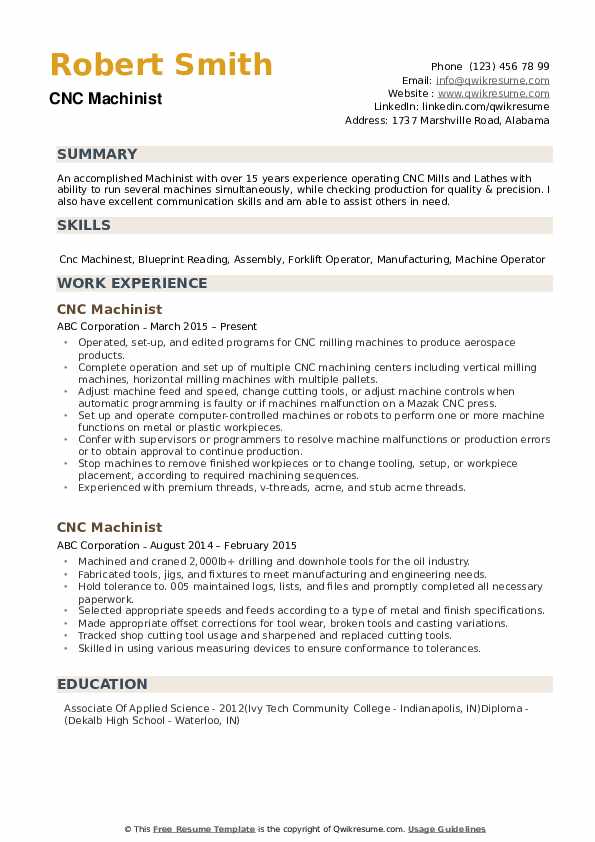

CNC Machinist Resume

Headline : Proficient CNC Machinist with 7 years of diverse experience in precision machining and programming within high-demand industries. Skilled in operating CNC mills and lathes, ensuring adherence to stringent quality standards. A collaborative team player dedicated to optimizing production processes and enhancing operational efficiency.

Skills : Inventory Management, Quality Control Inspection, Blueprint Interpretation, Tool Maintenance And Setup, Machining Operations, G-code Programming

Description :

- Monitored machine operations to identify and rectify issues such as tool wear and vibration, ensuring continuous production.

- Utilized precision measuring instruments to verify that finished workpieces conformed to specifications.

- Collaborated with programmers to validate new CNC programs, ensuring functionality and output quality.

- Executed setup and calibration of CNC machinery, optimizing performance for various production runs.

- Read and interpret blueprints, technical drawings, and CAD files for machining processes.

- Documented production metrics and maintained logs for quality assurance audits.

- Participated in continuous improvement initiatives to enhance production efficiency and reduce waste.

Experience

5-7 Years

Level

Senior

Education

AAS Machine Tech

Senior CNC Machinist Resume

Summary : Accomplished Senior CNC Machinist with a decade of expertise in precision machining and programming. Proficient in optimizing CNC mills and lathes for enhanced production efficiency and quality. Recognized for strong problem-solving abilities and leadership in fast-paced settings, committed to achieving operational excellence and continuous improvement.

Skills : Pneumatic Systems, Cnc Router Operation, Cnc Laser Operation, Cnc Plasma Cutting, Workplace Organization, Lean Manufacturing

Description :

- Maintained comprehensive logs and documentation, ensuring compliance with quality standards.

- Conducted thorough first piece inspections using precision gauges, ensuring product quality.

- Collaborated with engineers and quality control to troubleshoot machining issues effectively.

- Executed mathematical calculations for precise machining outcomes.

- Optimized machine settings and tools to enhance production efficiency.

- Programmed and operated CNC machines, particularly in the biomedical field.

- Safely operated various hand and power tools, including lathes and grinders.

- Interpreted complex blueprints to ensure adherence to customer specifications.

Experience

7-10 Years

Level

Management

Education

AAS Machining Tech

CNC Machinist Resume

Headline : Passionate CNC Machinist with 7 years of comprehensive experience in precision machining and programming. Expertise in operating advanced CNC mills and lathes while ensuring optimal quality and efficiency. Committed to enhancing production processes and fostering collaboration in high-pressure environments.

Skills : Time Management, Setup And Operation, Precision Measurement, Problem Solving, Lathe Operation, Milling Machine Skills

Description :

- Executed precise machine set-ups and program edits, enhancing production capabilities.

- Demonstrated proficiency in programming, setting up, and operating CNC turning and machining centers.

- Exhibited strong skills in interpreting complex blueprints and detailed work orders to ensure quality output.

- Maintained proactive communication with supervisors to facilitate smooth operations and resolve issues.

- Ensured compliance with safety regulations by maintaining a clean and organized workspace.

- Performed detailed inspections according to established specifications, ensuring quality assurance of parts.

- Set up and operated Swiss-style Tsunami BH38 machine, consistently delivering high-quality parts.

Experience

5-7 Years

Level

Senior

Education

AAS Machine Tool

Lead CNC Machinist Resume

Summary : Driven Lead CNC Machinist with over 10 years of extensive experience in precision machining and programming. Expert in optimizing CNC operations for maximum efficiency and quality. Proven track record in leading teams, enhancing production processes, and ensuring stringent adherence to safety and quality standards in dynamic manufacturing environments.

Skills : Autocad, Mastercam X6, Setup And Operation Of Cnc Mills And Lathes, Including Program Editing, Blueprint Reading And Gd&t Proficiency

Description :

- Oversaw CNC operations, ensuring adherence to production schedules and quality specifications.

- Set up, programmed, and operated CNC mills and lathes, enhancing efficiency and output.

- Collaborated with engineering teams to interpret blueprints and technical specifications accurately.

- Trained and mentored junior machinists, fostering a culture of continuous improvement and skill development.

- Maintained and calibrated CNC equipment to ensure optimal performance and reliability.

- Conducted regular inspections of finished components to guarantee compliance with quality standards.

- Utilized advanced measuring tools to verify dimensions and tolerances, ensuring precision in machining processes.

Experience

10+ Years

Level

Consultant

Education

AAS

CNC Machinist Resume

Objective : Accomplished CNC Machinist with 5 years of robust experience in precision machining and programming. Proficient in operating CNC mills and lathes, I consistently uphold stringent quality standards while enhancing production efficiency. My commitment to teamwork and process improvement drives success in high-demand manufacturing environments.

Skills : Cnc Milling Programming, Tool Path Optimization, Technical Documentation, Document Management, Operating Systems Knowledge, Windows Os Proficiency

Description :

- Dismantled and inspected components, conducting adjustments and repairs as necessary.

- Excelled in machine operation, inspection, problem-solving, setup, fixturing, and tooling requirements.

- Conduct quality inspections using precision measuring instruments like calipers and micrometers.

- Program CNC machines using G-code and M-code for efficient production runs.

- Performed production responsibilities involving inspection and gauging of various parts for quality assurance.

- Audited job requirements, allocated materials, and addressed unexpected issues with effective solutions.

- Reviewed technical specifications and drawings to determine the fastest, most cost-effective manufacturing methods.

Experience

2-5 Years

Level

Junior

Education

AAS Machining

CNC Machinist II Resume

Summary : Versatile CNC Machinist II with a decade of experience in precision machining across diverse industries. Expert in programming and operating CNC mills and lathes, ensuring adherence to high-quality standards. Committed to implementing continuous improvements and fostering collaboration to drive operational efficiency.

Skills : Drilling Techniques, Troubleshooting Skills, Machining Techniques, Safety Protocols, Quality Control, Machine Maintenance

Description :

- Interpreted complex blueprints and specifications to set up machining processes accurately.

- Operated advanced CNC mills and lathes, ensuring precision and adherence to quality standards.

- Utilized measuring instruments to verify compliance with specifications and tolerances.

- Implemented safety protocols to minimize workplace hazards and ensure compliance.

- Calculated and adjusted controls for optimal machining factors, including speed and feed rates.

- Performed routine maintenance and troubleshooting on CNC equipment to ensure peak performance.

- Collaborated with engineering teams to develop efficient machining solutions and improve workflows.

Experience

7-10 Years

Level

Management

Education

AAS

CNC Machinist Resume

Summary : Skilled CNC Machinist with a decade of extensive experience in precision machining and programming. Adept at operating CNC mills and lathes, I consistently deliver high-quality components while optimizing production processes. My focus on collaboration and continuous improvement drives operational excellence in demanding manufacturing environments.

Skills : Manual Machining, Mazak Lathe Programming And Operation, Forklift Operations, Prototrak Programming And Operation, Mastercam Software Proficiency, Solidworks Cad Design

Description :

- Recognized as a key resource for troubleshooting and resolving machining issues, enhancing team efficiency.

- Served as a setup instructor, effectively communicating technical information to engineers and operators.

- Conducted thorough inspections of manufactured parts, identifying defects and implementing corrective measures.

- Maintained and adjusted machine programs to ensure adherence to precise tolerances.

- Documented tool measurements in compliance with ISO 9001 quality standards.

- Operated CNC lathes with Fanuc controls, producing parts to exact blueprint specifications.

- Verified completed parts against specifications, ensuring high-quality output.

Experience

10+ Years

Level

Management

Education

AAS Machine Tech

CNC Machinist Resume

Objective : CNC Machinist with 2 years of specialized experience in precision machining and programming. Adept at operating CNC mills and lathes, with a strong focus on quality assurance and process optimization. Eager to contribute to a dynamic team, driving efficiency and excellence in manufacturing operations.

Skills : Cnc Machinist, Six Sigma Principles, Machining Assembly, Material Handling, Cnc Machine Operation

Description :

- Operated and programmed CNC milling machines to produce precision parts for aerospace applications.

- Set up multiple CNC machining centers, including vertical and horizontal mills, optimizing workflow.

- Adjusted machine parameters and replaced tools to maintain production quality and efficiency.

- Collaborated with engineers to troubleshoot and resolve machining issues promptly.

- Monitored production runs to ensure adherence to specifications and quality standards.

- Executed routine maintenance on CNC machines to ensure optimal performance.

- Utilized measuring instruments to verify part dimensions and tolerances.

Experience

0-2 Years

Level

Fresher

Education

AAS Machine Tech