CNC Programmer Resume

Objective : Detail-oriented CNC Programmer with 5 years of experience in programming, setting up, and operating CNC machines. Proven track record in optimizing machining processes and enhancing production efficiency.

Skills : CNC Programming, G-code Editing, Tool Path Creation, Machining Setup

Description :

- Transitioned the machine shop from manual to CNC machining, enhancing productivity.

- Created and optimized CNC programs for lathes, improving cycle times.

- Specialized in machining high-alloy stainless materials with precision.

- Trained new employees on CNC operations and safety standards.

- Developed software to automate CNC program generation for specific parts.

- Monitored job costs and inventory through custom software solutions.

- Implemented procedures for machining test samples for quality assurance.

Experience

2-5 Years

Level

Junior

Education

AAS CNC Tech

CNC Programmer/Operator Resume

Objective : Detail-oriented CNC Programmer with 2 years of experience in multi-axis machining. Proficient in MasterCAM and tool path verification, ensuring precision in aerospace part production and optimizing manufacturing processes.

Skills : Aerospace Machining, CNC Programming, Tool Path Verification, MasterCAM Software, Blueprint Interpretation

Description :

- Developed multi-axis CNC programs using MasterCAM for aerospace components, ensuring high precision.

- Utilized tool path verification software to validate CNC programs before production, minimizing errors.

- Analyzed material properties and geometries to enhance production efficiency and cycle times.

- Designed and fabricated tooling to streamline part manufacturing processes.

- Drafted and improved process documentation to boost safety, quality, and productivity.

- Collaborated with maintenance teams to implement timely modifications, reducing downtime.

- Provided training on CNC operations to production staff, improving overall team performance.

Experience

0-2 Years

Level

Entry Level

Education

AAS CNC Tech

CNC Programmer/Mill Machinist Resume

Summary : Detail-oriented CNC Programmer with 10 years of experience in programming, setup, and operation of CNC machines. Proven track record in optimizing processes and enhancing production efficiency through innovative programming solutions.

Skills : Toolpath Optimization, G-Code Proficiency, Fixture Design, Process Improvement, Tool Selection

Description :

- Developed and optimized CNC programs for various machines, enhancing production efficiency.

- Created and maintained setup sheets for CNC operations, ensuring accuracy and consistency.

- Monitored production processes from programming to assembly, ensuring quality standards.

- Utilized software tools like Microsoft Office and CAD for documentation and design.

- Operated and trained staff on CNC Finn-Power Turret Punch Presses, improving operational efficiency.

- Conducted machine maintenance and troubleshooting, minimizing downtime.

- Performed quality inspections on machined parts, ensuring compliance with specifications.

Experience

10+ Years

Level

Senior

Education

AAS CNC Tech

CNC Programmer/Machinist Resume

Summary : Detail-oriented CNC Programmer with 10 years of experience in programming, operating, and troubleshooting CNC machinery. Proven ability to optimize production processes and ensure precision in manufacturing.

Skills : CNC machine setup, Blueprint interpretation, Quality assurance, Troubleshooting skills, Data Analysis

Description :

- Measured designs to determine optimal cutting and welding methods for CNC operations.

- Programmed CNC machines based on detailed blueprints and specifications.

- Ensured accurate code entry and sequence for machine operations.

- Developed and implemented programs to enhance CNC machine speed and productivity.

- Minimized production downtime through proactive equipment maintenance.

- Promoted a safe and organized work environment, adhering to safety protocols.

- Collaborated with team members to assess daily production needs and priorities.

Experience

10+ Years

Level

Senior

Education

AAS CNC Tech

CNC Programmer/Draftsman Resume

Summary : Dedicated CNC Programmer with 10 years of experience in precision machining and programming. Proven track record in optimizing production processes and enhancing workflow efficiency. Committed to continuous learning and contributing to team success.

Skills : CATIA Software, NX CAD Software, CNC Programming, Blueprint Interpretation, Tool Path Optimization

Description :

- Expertly programmed and set up Okuma CNC 4-axis lathes, ensuring precision in machining operations.

- Maintained consistent workflow across CNC machines for day and night shifts, optimizing production efficiency.

- Logged all revisions and new programs in Excel, ensuring accurate documentation and traceability.

- Collaborated with machinists to troubleshoot issues, fostering effective communication and problem-solving.

- Assisted lead programmer in production updates, tool room organization, and running CNC machines as needed.

- Machined components from various materials, including stainless steel and exotic metals, ensuring adherence to specifications.

- Utilized precision measuring tools to verify dimensions and tolerances, maintaining high-quality standards.

Experience

7-10 Years

Level

Management

Education

AAS CNC Tech

CNC Programmer/Setup Resume

Headline : Detail-oriented CNC Programmer with 7 years of experience in programming, operating, and troubleshooting CNC machinery. Proven track record in optimizing production processes and ensuring high-quality standards.

Skills : CNC Programming, G-code Generation, Blueprint Interpretation, Toolpath Optimization

Description :

- Scheduled and coordinated production tasks, providing training and coaching to team members.

- Collaborated with supervisors to ensure optimal product quality and adherence to specifications.

- Utilized GibbsCAM and AutoCAD for effective CNC programming and design.

- Maintained strong communication with operators to implement best machining practices.

- Ensured accuracy of machine instructions, modifying programs to eliminate errors.

- Participated in weekly management meetings to discuss production improvements.

- Managed DNC stations for efficient uploads and downloads on CNC machines.

Experience

5-7 Years

Level

Executive

Education

AAS CNC Tech

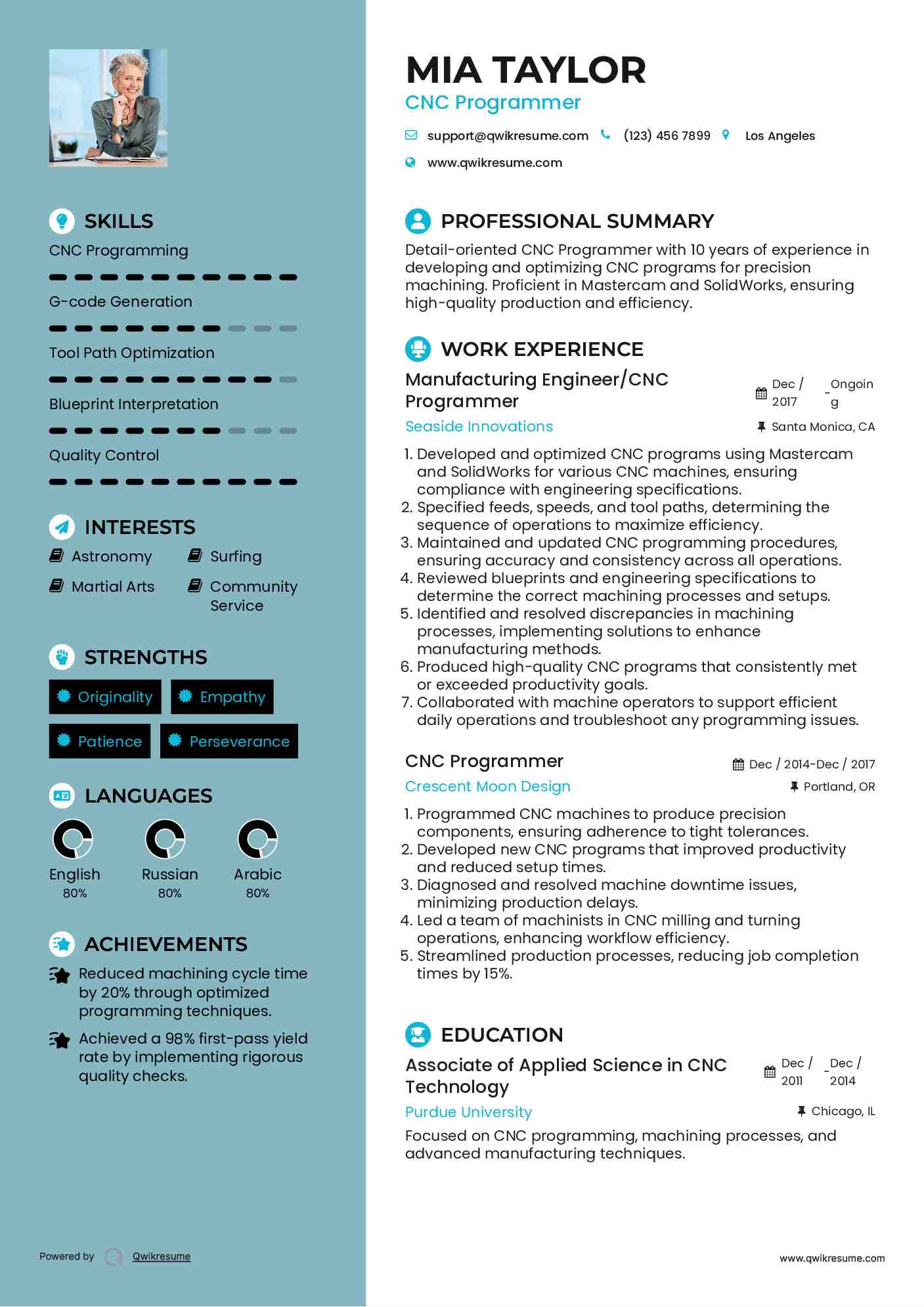

Manufacturing Engineer/CNC Programmer Resume

Summary : Detail-oriented CNC Programmer with 10 years of experience in developing and optimizing CNC programs for precision machining. Proficient in Mastercam and SolidWorks, ensuring high-quality production and efficiency.

Skills : CNC Programming, G-code Generation, Tool Path Optimization, Blueprint Interpretation, Quality Control

Description :

- Developed and optimized CNC programs using Mastercam and SolidWorks for various CNC machines, ensuring compliance with engineering specifications.

- Specified feeds, speeds, and tool paths, determining the sequence of operations to maximize efficiency.

- Maintained and updated CNC programming procedures, ensuring accuracy and consistency across all operations.

- Reviewed blueprints and engineering specifications to determine the correct machining processes and setups.

- Identified and resolved discrepancies in machining processes, implementing solutions to enhance manufacturing methods.

- Produced high-quality CNC programs that consistently met or exceeded productivity goals.

- Collaborated with machine operators to support efficient daily operations and troubleshoot any programming issues.

Experience

10+ Years

Level

Senior

Education

AAS CNC Tech

CNC Operator/CNC Programmer Resume

Objective : Detail-oriented CNC Programmer with 5 years of experience in programming and operating CNC machinery. Proven track record in optimizing production processes and enhancing efficiency through innovative programming solutions.

Skills : CNC Programming Software, Mazak Programming, Blueprint Interpretation, Toolpath Optimization, Quality Control Inspection

Description :

- Programmed and operated CNC mills and lathes, including live tooling and B-axis operations.

- Managed tooling orders and conducted proof runs for quality assurance before handoff.

- Designed and implemented a machining cell for a GE nitrous oxide injector for advanced jet engines.

- Utilized Rene41 material for high-performance components, ensuring precision and quality.

- Executed complex programming on Mori Seiki 9-axis NT 4250 and 5-axis Mori NMV 3000 machines.

- Leveraged extensive programming experience to reduce costs and enhance machining efficiency.

- Participated in the Esprit World Conference to advance programming skills and network with industry professionals.

Experience

2-5 Years

Level

Junior

Education

AAS CNC Tech

CNC Programmer/Technician Resume

Headline : Detail-oriented CNC Programmer with 7 years of experience in precision machining, programming, and setup. Proficient in interpreting blueprints and optimizing CNC operations for efficiency and quality.

Skills : CAD Software, Fixture Design, CNC Programming, Blueprint Interpretation, Quality Control

Description :

- Interprets blueprints and engineering drawings to plan machining operations accurately.

- Manages stock inventory using Strumis software, ensuring timely procurement and stock verification.

- Programs CNC mills and lathes, setting tool registers and offsets to meet production specifications.

- Sets up CNC machines by installing and adjusting chucks, tools, and attachments for optimal performance.

- Verifies machining settings and first-run parts, ensuring adherence to quality standards and specifications.

- Implements safety protocols and performs preventive maintenance on CNC equipment to minimize downtime.

- Documents production processes and communicates with team members to maintain workflow continuity.

Experience

5-7 Years

Level

Executive

Education

AAS CNC Tech

CNC Programmer And Machinist Resume

Objective : Detail-oriented CNC Programmer with 5 years of experience in programming and operating CNC machines. Proficient in Gibbs CAM and SolidWorks, with a strong focus on efficiency and quality in manufacturing processes.

Skills : Gibbs CAM, SolidWorks, Tooling Selection, Production Planning

Description :

- Oversee CNC programming and operations using Gibbs CAM to ensure precision and quality.

- Analyze project requirements to select appropriate tooling for timely completion.

- Collaborate with management to develop tooling procedures and streamline operations.

- Program CNC machines, including vertical and horizontal mills, ensuring optimal performance.

- Design and create fixtures in SolidWorks, including detailed prints and material lists.

- Conduct training sessions for CNC operators to enhance skills and operational efficiency.

- Propose and implement procedural improvements, resulting in increased efficiency and quality.

Experience

2-5 Years

Level

Junior

Education

AAS CNC Tech

Manufacturing Manager/CNC Programmer Resume

Summary : Detail-oriented CNC Programmer with 10 years of experience in precision machining and programming. Proficient in optimizing CNC operations, enhancing productivity, and ensuring quality control in manufacturing processes.

Skills : CNC Programming, CNC Setup, Precision Measurement, Troubleshooting, Process Improvement

Description :

- Operated and programmed CNC machines, ensuring precision and adherence to specifications.

- Monitored machine performance, conducting routine maintenance to prevent downtime.

- Utilized various measuring tools to verify product dimensions and tolerances.

- Collaborated with engineering teams to interpret blueprints and make necessary adjustments.

- Trained new operators on CNC programming and machine operation best practices.

- Documented production processes and maintained accurate logs for quality assurance.

- Implemented process improvements that enhanced production efficiency and reduced waste.

Experience

7-10 Years

Level

Management

Education

GED

CNC Programmer/Tooling Design Resume

Summary : Dedicated CNC Programmer with over 10 years of experience in programming, operating, and troubleshooting CNC machinery. Proven track record in optimizing production processes and enhancing product quality.

Skills : Precision machining techniques, Blueprint interpretation, Quality control processes, Toolpath optimization, CNC machine setup

Description :

- Designed and implemented CNC programs for various projects, ensuring precision and efficiency.

- Conducted thorough research on new CNC technologies and techniques to enhance production capabilities.

- Established and enforced project management protocols, resulting in improved workflow and productivity.

- Maintained strong customer relations, facilitating quick resolutions to technical issues.

- Reviewed engineering drawings and made necessary adjustments to CNC programs for optimal performance.

- Led training sessions for new hires, ensuring adherence to safety and operational standards.

- Analyzed production data to achieve 100% customer satisfaction with timely delivery of over 50,000 program designs.

Experience

7-10 Years

Level

Management

Education

Associate In Applied Science

CNC Programmer And Operator Resume

Summary : Detail-oriented CNC Programmer with 10 years of experience in programming, setup, and operation of CNC machines. Proven track record in optimizing machining processes and ensuring high-quality production standards.

Skills : CNC Programming, Toolpath Optimization, Machine Setup, Quality Control, Troubleshooting

Description :

- Utilized NX7 to determine machining sequences and select appropriate cutting tools for precision workpieces.

- Revised CNC programs to eliminate errors, ensuring efficient production and quality standards.

- Analyzed job orders and blueprints to calculate dimensions, tool selection, and machine speeds for optimal performance.

- Computed reference points and machine paths, ensuring accuracy in angular and linear dimensions.

- Conducted trial runs and simulations to verify program functionality and adherence to specifications.

- Verified program accuracy by comparing encoded tapes with original specifications and blueprints.

- Entered coordinates into program memories, ensuring precise machine operation.

Experience

7-10 Years

Level

Management

Education

GED

CNC Programmer Resume

Objective : Detail-oriented CNC Programmer with 5 years of experience in precision machining and programming. Proficient in optimizing production processes and ensuring high-quality standards in manufacturing environments.

Skills : Safety Compliance Expertise, CNC Programming, G-code Proficiency, Tool Path Optimization, Blueprint Interpretation

Description :

- Enhanced production efficiency by transitioning from DOS-based programming to advanced FeatureCAM software.

- Programmed various CNC machines, including Mori-Seiki and Mitsubishi, ensuring precision and quality.

- Designed and optimized tooling using FeatureCAM solid modeling, improving production capabilities.

- Reviewed and validated production prints to maintain compliance with specifications.

- Oversaw the selection and procurement of cutting tools, ensuring cost-effectiveness.

- Coordinated work schedules and assignments for the Tool Room, optimizing workflow.

- Provided technical support and training to machine operators, enhancing operational efficiency.

Experience

2-5 Years

Level

Junior

Education

Diploma