CNC Service Engineer Resume

Summary : With a decade of experience as a CNC Service Engineer, I excel in diagnosing and resolving complex technical issues across a wide range of CNC machinery. My expertise encompasses the installation, calibration, and maintenance of advanced CNC systems, ensuring optimal performance and customer satisfaction. I am committed to delivering high-quality service and training to clients, empowering them to leverage the full capabilities of their equipment.

Skills : CNC Programming and Operation, Troubleshooting and Diagnostics, Preventive Maintenance, Customer Relationship Management

Description :

- Specialized in the installation and calibration of CNC machines, ensuring precise operation according to specifications.

- Provided exceptional after-sales support, addressing customer inquiries and resolving machine-related issues efficiently.

- Developed and maintained comprehensive standard operating procedures for all service activities.

- Performed detailed diagnostics and troubleshooting on Fanuc and Mitsubishi controllers.

- Conducted training sessions for clients on machine operation and maintenance, fostering stronger client relationships.

- Collaborated with engineering teams to design and implement effective solutions for machine enhancements.

- Maintained accurate service records and reports for all client interactions and machine services.

Experience

10+ Years

Level

Senior

Education

BSc ME

CNC Service Engineer Resume

Summary : Results-driven CNC Service Engineer skilled in diagnosing complex mechanical issues and implementing innovative solutions. Successfully improved machine performance by 30% through proactive maintenance and customer training initiatives.

Skills : Electrical Troubleshooting, Troubleshooting Skills, Technical Documentation, Preventive Maintenance, Electrical Systems Knowledge

Description :

- Installed, troubleshot, and performed preventive maintenance on various CNC machine tools to ensure optimal performance.

- Provided timely and effective technical support to clients, addressing inquiries and resolving issues efficiently.

- Conducted machine demonstrations and training sessions for clients to enhance their operational proficiency.

- Reviewed and optimized production processes on-site to improve efficiency and reduce waste.

- Maintained detailed documentation of service contracts, maintenance activities, and client communications.

- Utilized technical manuals and schematics to perform repairs and maintenance on CNC equipment.

- Collaborated with engineering teams to develop solutions for complex technical challenges in CNC operations.

Experience

7-10 Years

Level

Management

Education

B.Sc. ME

CNC Service Engineer Resume

Headline : A seasoned CNC Service Engineer with over 7 years of hands-on experience in the maintenance and troubleshooting of CNC machinery. Proven expertise in optimizing equipment performance through effective diagnostics, installation, and calibration of complex systems.

Skills : CNC Programming, Technical Troubleshooting, CNC Machinery Installation, Preventive Maintenance, Client Training and Support

Description :

- Diagnosed and repaired mechanical, hydraulic, and electrical systems on CNC equipment to ensure optimal performance.

- Guided clients via telephone and on-site visits to enhance their understanding of machinery operation and maintenance.

- Coordinated maintenance efforts with application engineers, ensuring timely service delivery and resolution of technical issues.

- Installed and configured new CNC machine tools at client locations, ensuring adherence to specifications and safety standards.

- Inspected machinery for damage and identified root causes of issues, implementing effective solutions.

- Executed the installation and termination of electrical panels in compliance with technical drawings.

- Troubleshot PLC hardware issues, including I/O modules, enhancing overall equipment functionality.

Experience

5-7 Years

Level

Executive

Education

AAS-CNC

CNC Service Engineer Resume

Objective : An accomplished CNC Service Engineer with 5 years of specialized experience in troubleshooting and enhancing CNC machinery performance. Adept at executing installation, calibration, and maintenance tasks to maximize operational efficiency and ensure client satisfaction. I thrive on providing exceptional technical support and training, empowering users to maximize their equipment's potential.

Skills : Technical Communication, CNC Programming, Machinery Diagnostics, Blueprint Reading, Quality Control Standards

Description :

- Maintained and repaired CNC equipment, conducted preventative maintenance, and implemented modifications to optimize performance.

- Responded to service calls for FANUC products, including CNC machines, robots, and specialized equipment like Robodrill and Robocut.

- Delivered comprehensive technical support, accurately diagnosing and resolving customer challenges to ensure seamless operations.

- Built strong relationships with key stakeholders, enhancing service delivery and customer satisfaction.

- Conducted system analysis and data interpretation, providing actionable recommendations for performance improvements.

- Promoted spare parts and consumables to existing customers, driving increased sales and service contracts.

- Advocated for value-added services such as Preventive Maintenance Contracts and health checks, enhancing customer loyalty.

Experience

2-5 Years

Level

Executive

Education

B.S. ME

CNC Service Engineer Resume

Summary : Bringing ten years of extensive experience as a CNC Service Engineer, I specialize in the comprehensive maintenance and troubleshooting of sophisticated CNC machinery. My background includes the successful installation and calibration of systems, as well as a strong commitment to enhancing operational efficiency through tailored training and support for clients. I pride myself on fostering long-term relationships with customers by ensuring their equipment performs at peak levels.

Skills : CNC Diagnostic Tools, Programming CNC Machines, Precision Measurement, Hydraulic Systems, Software Proficiency, Customer Service Skills

Description :

- Reported directly to the Service Manager while installing, commissioning, and servicing 45-axis horizontal CNC machines.

- Scheduled and performed maintenance on horizontal machines and associated automation in compliance with internal service standards.

- Conducted site visits to repair and service machines, developing strong relationships with customers.

- Provided technical support to customers and colleagues regarding the G-Module range of machines and automation.

- Participated in hotline and emergency support as necessary, demonstrating problem-solving skills.

- Guided customers on best practices for machine maintenance to enhance longevity and performance.

- Ensured compliance with health and safety regulations according to stringent internal and customer standards.

Experience

10+ Years

Level

Senior

Education

B.S. in ME

CNC Service Engineer Resume

Summary : An accomplished CNC Service Engineer with a decade of extensive experience in optimizing and maintaining sophisticated CNC machinery. I possess a strong track record in troubleshooting complex technical issues and implementing effective solutions to enhance machine performance. My commitment to providing exceptional service and client training has consistently resulted in improved operational efficiency and customer satisfaction.

Skills : CNC Programming, Machine Calibration, Preventive Maintenance, Mechanical Systems Knowledge

Description :

- Interpreted and executed complex mechanical and electrical schematics for CNC machinery.

- Utilized precision measuring tools to ensure accurate machine setup and performance.

- Adhered to strict safety protocols, including customer-specific requirements, while conducting Risk Assessments and Method Statements.

- Delivered exceptional customer service, maintaining professionalism and a customer-focused approach.

- Maintained confidentiality in accordance with Non-Disclosure agreements during service operations.

- Collaborated with team members to enhance service delivery, often working overtime and on weekends to meet client needs.

- Executed critical breakdown repairs on-site, ensuring minimal disruption to production schedules.

Experience

7-10 Years

Level

Management

Education

B.S. Mech. Eng.

CNC Service Engineer Resume

Headline : As a dedicated CNC Service Engineer with over 7 years of hands-on experience, I specialize in the intricate maintenance and troubleshooting of CNC machinery. My background encompasses the effective installation, calibration, and optimization of advanced CNC systems, consistently enhancing operational performance. I am passionate about providing comprehensive technical support and training, ensuring clients fully utilize their equipment's capabilities and achieve optimal productivity.

Skills : CNC Programming, Preventive Maintenance, Technical Support, Troubleshooting, System Calibration

Description :

- Updated all service and inspection documents for the machinery to ensure compliance with industry standards.

- Developed strong customer relationships by delivering exceptional on-site support and service.

- Provided comprehensive technical and troubleshooting assistance to customers as needed.

- Troubleshot and repaired CNC machines, control motors, drives, industrial lasers, and precision equipment.

- Diagnosed and resolved both minor and major technical and mechanical issues with CNC instruments.

- Managed overseas servicing and maintenance projects, ensuring timely and effective solutions.

- Maintained and respected all company property, equipment, and tools to the highest standards.

Experience

5-7 Years

Level

Executive

Education

B.S. ME

CNC Service Engineer Resume

Headline : A highly skilled CNC Service Engineer with over 7 years of dedicated experience in the maintenance and optimization of CNC machinery. My proficiency lies in diagnosing and resolving complex technical issues, ensuring seamless installation and calibration of advanced systems. I have a proven track record of enhancing machine performance through strategic maintenance and client training, driving operational efficiency and customer satisfaction.

Skills : CNC Machine Setup and Installation, Technical Troubleshooting, Preventive Maintenance, Customer Training and Support, System Calibration

Description :

- Executed installation, calibration, and maintenance of CNC machinery, ensuring optimal operational performance.

- Diagnosed and resolved technical issues effectively, enhancing machine reliability and reducing downtime.

- Collaborated with quality control and maintenance teams to elevate product quality and performance standards.

- Provided comprehensive training to operators and engineers on CNC machine functionalities and troubleshooting techniques.

- Communicated with clients to gather requirements and deliver tailored technical support, enhancing customer satisfaction.

- Assisted senior engineers in developing and implementing improvements in CNC manufacturing procedures.

- Maintained accurate records of service activities and machine performance to inform future maintenance strategies.

Experience

5-7 Years

Level

Executive

Education

B.S. Mech. Eng.

CNC Service Engineer Resume

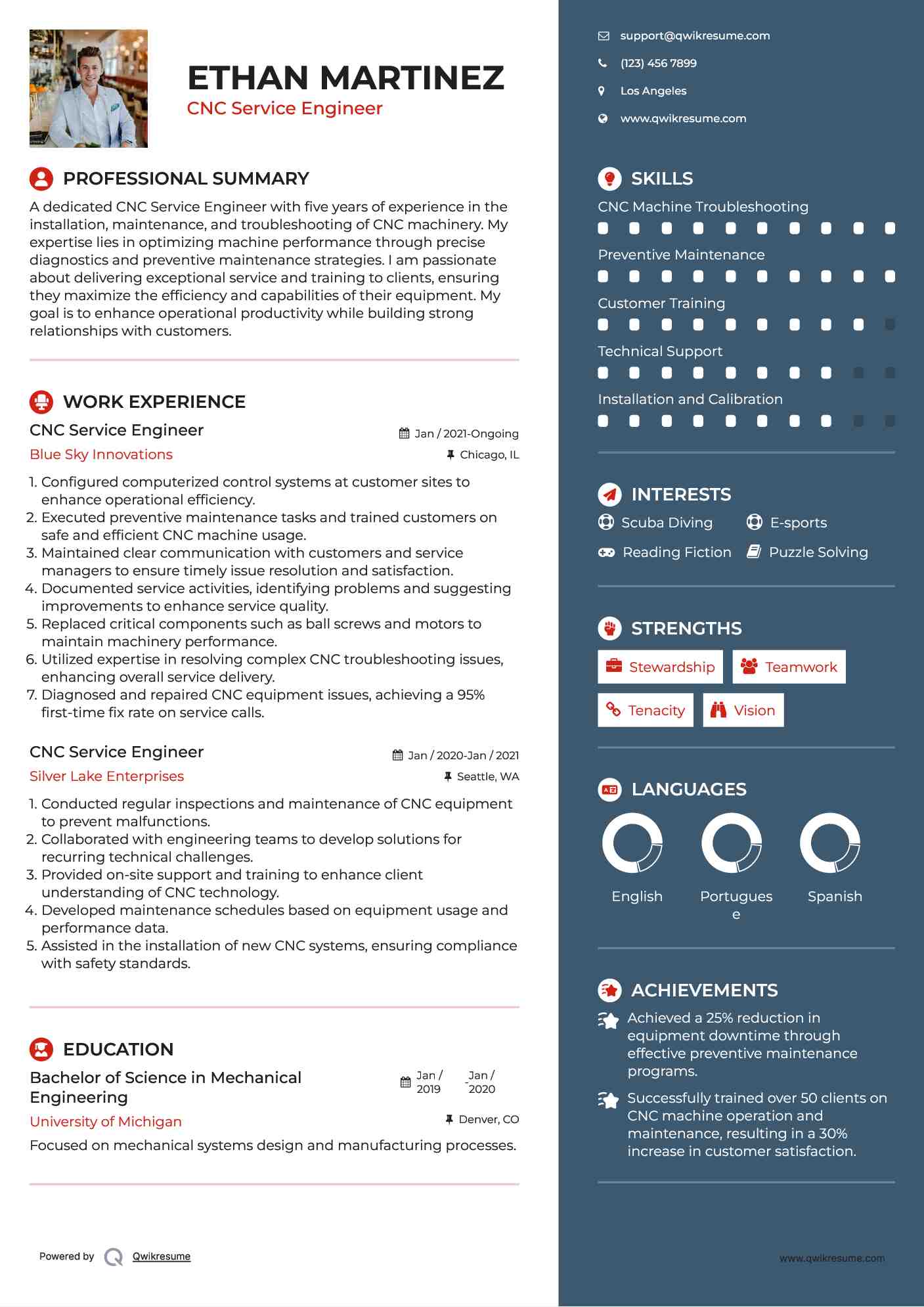

Objective : A dedicated CNC Service Engineer with five years of experience in the installation, maintenance, and troubleshooting of CNC machinery. My expertise lies in optimizing machine performance through precise diagnostics and preventive maintenance strategies. I am passionate about delivering exceptional service and training to clients, ensuring they maximize the efficiency and capabilities of their equipment. My goal is to enhance operational productivity while building strong relationships with customers.

Skills : CNC Machine Troubleshooting, Preventive Maintenance, Customer Training, Technical Support, Installation and Calibration

Description :

- Configured computerized control systems at customer sites to enhance operational efficiency.

- Executed preventive maintenance tasks and trained customers on safe and efficient CNC machine usage.

- Maintained clear communication with customers and service managers to ensure timely issue resolution and satisfaction.

- Documented service activities, identifying problems and suggesting improvements to enhance service quality.

- Replaced critical components such as ball screws and motors to maintain machinery performance.

- Utilized expertise in resolving complex CNC troubleshooting issues, enhancing overall service delivery.

- Diagnosed and repaired CNC equipment issues, achieving a 95% first-time fix rate on service calls.

Experience

2-5 Years

Level

Executive

Education

B.S. ME

CNC Service Engineer Resume

Objective : Innovative and results-oriented CNC Service Engineer with 5 years of experience in the installation, maintenance, and optimization of CNC machinery. I have a proven ability to troubleshoot complex technical challenges and implement effective solutions that enhance machine performance and reliability. My commitment to providing thorough training and support empowers clients to fully utilize their equipment, driving operational excellence and satisfaction.

Skills : CNC Machine Troubleshooting, Pneumatic Systems, Time Management, Problem-Solving Skills, Team Collaboration, Installation Skills

Description :

- Conducted installation, commissioning, and troubleshooting of CNC machines at client sites.

- Diagnosed and repaired electrical, mechanical, and software issues in a timely and efficient manner.

- Provided comprehensive training to machine operators and maintenance staff on CNC system operation and routine maintenance.

- Collaborated with cross-functional teams to address complex technical challenges and optimize CNC machine performance.

- Documented service activities, including troubleshooting steps, repairs, and recommendations for future maintenance.

- Responded to service calls and performed on-site diagnosis and repair of CNC equipment.

- Performed preventive maintenance on CNC machines, reducing downtime by 30% and increasing productivity.

Experience

2-5 Years

Level

Executive

Education

B.S. Mech. Eng.