Industrial Maintenance Technician Resume

Objective : Proficient Industrial Maintenance Technician with two years of hands-on experience in troubleshooting, repairing, and maintaining hydraulic, pneumatic, and electrical systems. Skilled in optimizing machine performance and implementing preventative maintenance programs. Committed to ensuring safety and efficiency in all operations while fostering teamwork and collaboration.

Skills : Technical Documentation, Industrial Equipment Maintenance, Preventative Maintenance Strategies, Electrical Troubleshooting

Description :

- Troubleshot and repaired hydraulic, electrical, and robotic systems for plastic injection molding presses.

- Maintained and operated nitrogen and plastic resin transfer systems, ensuring operational efficiency.

- Fabricated fixtures and completed work orders to support production processes.

- Installed 300hp motors, utilizing forklifts and cranes safely and efficiently.

- Modified robotic programming to enhance operational efficiency and reduce cycle times.

- Collaborated with production teams to minimize downtime and optimize workflow.

- Executed job responsibilities with a strong emphasis on safety and compliance.

Experience

0-2 Years

Level

Entry Level

Education

AAS

Senior Industrial Maintenance Technician Resume

Summary : Accomplished Senior Industrial Maintenance Technician with over 10 years of experience in troubleshooting and maintaining complex hydraulic, pneumatic, and electrical systems. Expertise in optimizing operational efficiency through effective preventative maintenance and team leadership. Driven to enhance safety standards while fostering a collaborative work environment.

Skills : Precision Machining, Forklift Operation, Industrial Safety Protocols, Quality Control, Equipment Calibration

Description :

- Executed comprehensive repair and maintenance of diverse industrial machinery to ensure optimal performance.

- Fabricated and customized replacement parts to enhance equipment functionality.

- Diagnosed and resolved electrical issues in manufacturing environments, minimizing operational disruptions.

- Conducted scheduled preventative maintenance tasks to prolong equipment lifespan and reliability.

- Performed precise pipe fitting according to various application specifications.

- Expertly wired and maintained commercial electrical systems to meet industry standards.

- Collaborated with cross-functional teams to enhance operational workflows and safety protocols.

Experience

7-10 Years

Level

Senior

Education

AAS

Industrial Maintenance Technician Resume

Headline : Dedicated Industrial Maintenance Technician with 7 years of comprehensive experience in diagnosing, repairing, and maintaining diverse industrial equipment. Proficient in hydraulic, pneumatic, and electrical systems, with a strong focus on enhancing operational efficiency and implementing effective preventative maintenance strategies. Passionate about promoting safety and reliability in all maintenance operations.

Skills : Industrial Equipment Diagnostics, Problem-solving Skills, Equipment Installation, System Diagnostics, Technical Support, Regulatory Compliance

Description :

- Interpreted blueprints and manufacturer's manuals to ensure proper machinery installation and operation.

- Diagnosed equipment issues using test results, error codes, and operator feedback.

- Managed inventory of parts and materials, ensuring timely ordering and replenishment.

- Disassembled machinery for repairs, inspecting components for wear and defects.

- Executed repairs and maintenance on various industrial production equipment.

- Demonstrated machine functions and capabilities to operators for optimal use.

- Collaborated with team members to enhance overall operational efficiency.

Experience

5-7 Years

Level

Senior

Education

AAS

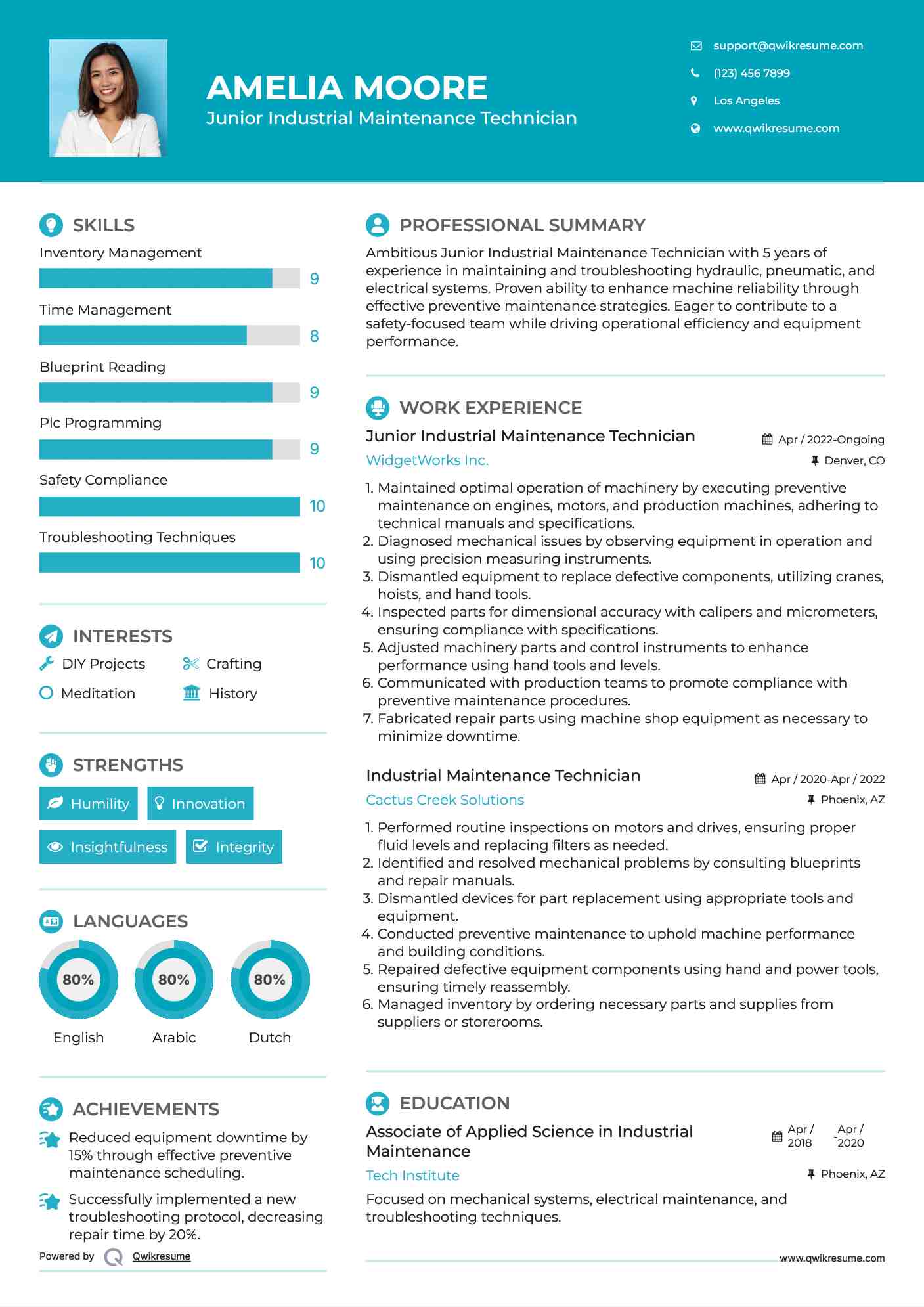

Junior Industrial Maintenance Technician Resume

Objective : Ambitious Junior Industrial Maintenance Technician with 5 years of experience in maintaining and troubleshooting hydraulic, pneumatic, and electrical systems. Proven ability to enhance machine reliability through effective preventive maintenance strategies. Eager to contribute to a safety-focused team while driving operational efficiency and equipment performance.

Skills : Inventory Management, Time Management, Blueprint Reading, Plc Programming, Safety Compliance, Troubleshooting Techniques

Description :

- Maintained optimal operation of machinery by executing preventive maintenance on engines, motors, and production machines, adhering to technical manuals and specifications.

- Diagnosed mechanical issues by observing equipment in operation and using precision measuring instruments.

- Dismantled equipment to replace defective components, utilizing cranes, hoists, and hand tools.

- Inspected parts for dimensional accuracy with calipers and micrometers, ensuring compliance with specifications.

- Adjusted machinery parts and control instruments to enhance performance using hand tools and levels.

- Communicated with production teams to promote compliance with preventive maintenance procedures.

- Fabricated repair parts using machine shop equipment as necessary to minimize downtime.

Experience

2-5 Years

Level

Junior

Education

AAS

Industrial Maintenance Technician Resume

Summary : Dynamic Industrial Maintenance Technician with a decade of extensive experience in troubleshooting, repairing, and maintaining complex machinery and systems. Expert in enhancing equipment reliability and performance through strategic preventative maintenance and innovative solutions. Eager to leverage skills to contribute to a high-performing team focused on safety and operational excellence.

Skills : Hydraulic System Maintenance, Emergency Response Skills, Industrial Cleaning, Parts Replacement, Maintenance Scheduling, Troubleshooting Software

Description :

- Oversaw maintenance and repair of multiple welding and quality inspection machines, ensuring optimal performance.

- Engineered and implemented a Production Monitor system for real-time production tracking.

- Designed and installed operator safety switches on all welding machines to enhance safety protocols.

- Configured advanced camera systems for part verification during the welding process.

- Created a thread verification machine to ensure thread accuracy post-welding.

- Developed and wrote PLC programs for machine operations, improving automation processes.

- Fabricated custom parts using machining tools, enhancing equipment functionality.

Experience

10+ Years

Level

Senior

Education

AAS

Lead Industrial Maintenance Technician Resume

Headline : Skilled Lead Industrial Maintenance Technician with 7 years of extensive experience in diagnosing, repairing, and optimizing industrial systems. Expertise in hydraulic, pneumatic, and electrical systems, coupled with a strong commitment to safety and operational excellence. Adept at leading teams and implementing effective maintenance strategies that enhance productivity and reliability.

Skills : System Installation, Team Leadership, Preventive Maintenance, Mechanical Repair

Description :

- Conducted thorough preventive maintenance on machinery to maximize operational efficiency and minimize downtime.

- Diagnosed and repaired hydraulic, pneumatic, and electrical systems to ensure peak performance.

- Implemented continuous improvement initiatives to enhance equipment reliability and reduce maintenance costs.

- Trained and supervised junior technicians, fostering a collaborative and safety-focused work environment.

- Worked effectively in various environmental conditions, maintaining productivity and safety standards.

- Utilized advanced diagnostic tools to troubleshoot complex machinery issues quickly and accurately.

- Collaborated with cross-functional teams to optimize production processes and address equipment needs.

Experience

5-7 Years

Level

Management

Education

AAS

Industrial Maintenance Technician Resume

Objective : Versatile Industrial Maintenance Technician with two years of practical experience in maintaining and troubleshooting mechanical, hydraulic, and electrical systems. Adept at executing preventive maintenance strategies to enhance equipment reliability and operational safety. Eager to contribute technical expertise and a proactive approach to a dynamic maintenance team.

Skills : Hydraulic Systems Maintenance, Industrial Automation, Electrical Wiring, Circuit Analysis, Power Distribution, Tool Operation

Description :

- Utilized hand and power tools for maintenance tasks, ensuring precision in repairs and installations.

- Executed inspections and tests on machinery to identify and troubleshoot malfunctions.

- Interpreted blueprints and manuals to guide repair processes and equipment assembly.

- Performed maintenance tasks including lubrication, cleaning, and adjustments on various machines.

- Repaired defective parts using hand and power tools, ensuring equipment functionality.

- Maintained accurate records of maintenance activities and equipment performance.

- Collaborated with team members to enhance maintenance workflows and safety protocols.

Experience

0-2 Years

Level

Entry Level

Education

AAS

Assistant Industrial Maintenance Technician Resume

Summary : Dedicated Assistant Industrial Maintenance Technician with a decade of experience in maintaining and optimizing industrial machinery. Proficient in troubleshooting hydraulic, pneumatic, and electrical systems, implementing preventative maintenance, and enhancing operational efficiency. Committed to upholding safety standards and fostering a collaborative work environment.

Skills : Mechanical Troubleshooting, Equipment Diagnostics, Hydraulic System Repair, Equipment Coating And Finishing, Preventative Equipment Servicing, Team Coordination

Description :

- Performed routine maintenance on machinery to ensure optimal performance and reduce downtime.

- Specialized in hydraulic, pneumatic, and electrical systems.

- Ensured compliance with safety protocols and operational standards.

- Executed all work procedures according to company regulations.

- Facilitated clear communication with supervisors and team members on tasks assigned.

- Utilized problem-solving and critical thinking skills in high-pressure situations.

- Calibrated and balanced new equipment post-installation for optimal performance.

Experience

7-10 Years

Level

Management

Education

AAS

Industrial Maintenance Technician Resume

Objective : Seasoned Industrial Maintenance Technician with 5 years of extensive experience in diagnosing and resolving mechanical, electrical, and hydraulic issues. Proven track record in implementing preventive maintenance strategies to optimize equipment performance. Committed to enhancing operational safety and efficiency while collaborating effectively with cross-functional teams.

Skills : Safety Protocols, Conveyor Systems, Motor Controls, Hydraulic Systems, Pneumatic Systems, Welding Techniques

Description :

- Troubleshot and repaired electrical and electronic control circuits to ensure optimal performance.

- Conducted inspections and tests on machinery to accurately diagnose malfunctions.

- Assembled wiring and electrical components, ensuring compliance with safety standards.

- Repaired and replaced faulty components in industrial machinery and equipment.

- Monitored fluid levels and replaced filters to maintain equipment efficiency.

- Documented maintenance and repair work, tracking costs and resource allocation.

- Requested supplies and equipment necessary for maintenance operations.

Experience

2-5 Years

Level

Junior

Education

A.A.S.

Associate Industrial Maintenance Technician Resume

Summary : Seasoned Industrial Maintenance Technician with 10 years of extensive expertise in troubleshooting, repairing, and maintaining complex hydraulic, pneumatic, and electrical systems. Focused on enhancing equipment reliability and operational efficiency through strategic preventative maintenance initiatives. Dedicated to fostering a safe, collaborative work environment while driving continuous improvement.

Skills : Industrial Systems Management, Equipment Monitoring Techniques, Bearing Replacement, Gearbox Maintenance

Description :

- Conducted regular maintenance of production machinery utilizing electrical, pneumatic, and mechanical principles to ensure optimal performance.

- Developed and proposed innovative ideas for machine improvements, enhancing productivity and efficiency.

- Provided comprehensive feedback on daily machine performance through written and verbal reports.

- Acted as a key member of the plant Safety Committee, promoting safety standards across operations.

- Coordinated system design changes to maximize automation, safety, and reliability in production processes.

- Collaborated on new equipment acquisitions to ensure alignment with production output goals.

- Maintained a clean and organized work area to promote safety and efficiency.

Experience

10+ Years

Level

Executive

Education

AAS

Industrial Maintenance Technician Resume

Objective : Skilled Industrial Maintenance Technician with 5 years of experience in diagnosing, repairing, and maintaining complex mechanical, electrical, and hydraulic systems. Proficient in executing preventative maintenance strategies that enhance operational efficiency and minimize downtime. Dedicated to fostering a safe work environment while driving continuous improvements in maintenance practices.

Skills : Project Oversight, Facility Maintenance, Electrical Systems Repair, Industrial Safety, Lockout/tagout Procedures

Description :

- Maintained and repaired boiler systems to ensure optimal steam production for operations.

- Diagnosed mechanical and electrical failures in boiler systems, implementing effective solutions.

- Installed and troubleshot HVAC systems and components to enhance climate control.

- Conducted maintenance and emergency repairs on fire sprinkler systems, ensuring compliance with safety standards.

- Created computer-based training programs to enhance technicians' problem-solving skills.

- Authored technical manuals for equipment maintenance, improving technician efficiency.

- Oversaw training for 127 maintenance technicians, evaluating skills for career advancement opportunities.

Experience

2-5 Years

Level

Executive

Education

AAS

Industrial Maintenance Technician Resume

Objective : Accomplished Industrial Maintenance Technician with 5 years of hands-on experience in diagnosing, repairing, and maintaining hydraulic, pneumatic, and electrical systems. Adept at implementing preventative maintenance protocols that enhance equipment reliability and operational efficiency. Committed to fostering a safe working environment while driving continuous improvement in maintenance practices.

Skills : Machine Calibration, Vibration Analysis, Troubleshooting Skills, Team Collaboration, Root Cause Analysis

Description :

- Maintained effective communication between shifts to ensure smooth operations.

- Utilized various welding techniques, including MIG and TIG, for assembling parts.

- Coordinated maintenance procedures and modifications, including machinery replacements.

- Set up and verified safety equipment functionality, ensuring compliance with standards.

- Assisted machine operators in quality checks for finished products.

- Performed machinery repairs and preventive maintenance, accurately logging downtime and parts used.

- Modified machinery through PLC programming and electrical rewiring to enhance performance.

Experience

2-5 Years

Level

Junior

Education

AAS