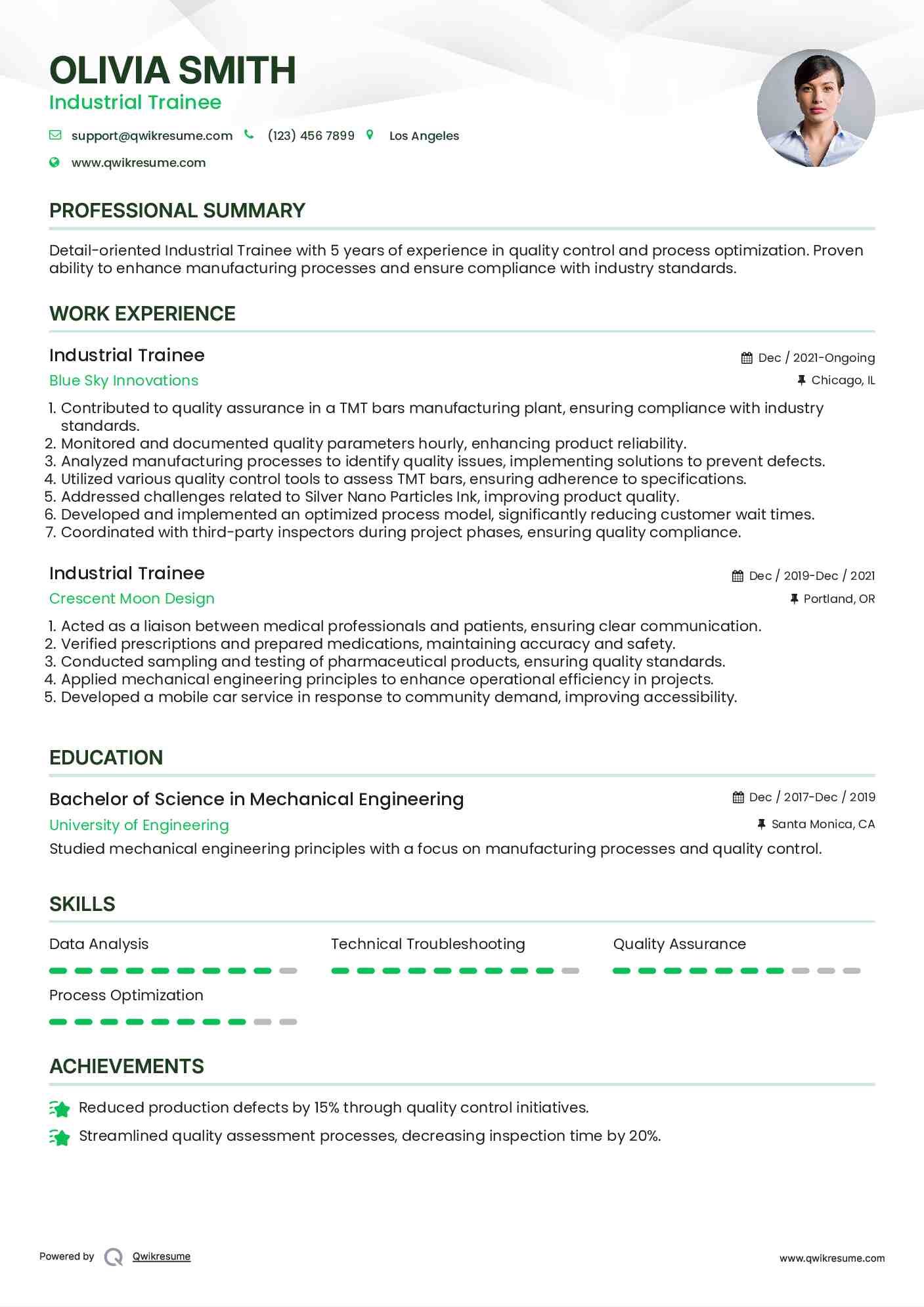

Industrial Trainee Resume

Objective : Detail-oriented Industrial Trainee with 5 years of experience in quality control and process optimization. Proven ability to enhance manufacturing processes and ensure compliance with industry standards.

Skills : Data Analysis, Technical Troubleshooting, Quality Assurance, Process Optimization

Description :

- Contributed to quality assurance in a TMT bars manufacturing plant, ensuring compliance with industry standards.

- Monitored and documented quality parameters hourly, enhancing product reliability.

- Analyzed manufacturing processes to identify quality issues, implementing solutions to prevent defects.

- Utilized various quality control tools to assess TMT bars, ensuring adherence to specifications.

- Addressed challenges related to Silver Nano Particles Ink, improving product quality.

- Developed and implemented an optimized process model, significantly reducing customer wait times.

- Coordinated with third-party inspectors during project phases, ensuring quality compliance.

Experience

2-5 Years

Level

Executive

Education

BSc ME

Industrial Trainee Resume

Objective : Detail-oriented Industrial Trainee with 5 years of experience in petroleum engineering. Proficient in reservoir modeling, well performance analysis, and safety protocols. Committed to enhancing operational efficiency and safety in oil and gas production.

Skills : Reservoir Engineering, Data Analysis, Safety Compliance, Well Performance Analysis, Technical Support

Description :

- Developed expertise in well testing and performance prediction using Nodal Analysis techniques.

- Modelled reservoirs and oil wells utilizing MBAL, PROSPER, and GAP software tools.

- Gained insights into Floating Production Storage and Offloading vessel operations.

- Learned various water flooding injection techniques to enhance oil recovery.

- Acquired knowledge on reservoir classifications, properties, and petroleum accumulation methods.

- Participated in safety and I-CARE training sessions to ensure compliance with industry standards.

- Collaborated with supervisors to observe and improve team handling and project execution.

Experience

2-5 Years

Level

Executive

Education

BSc PE

Industrial Trainee Resume

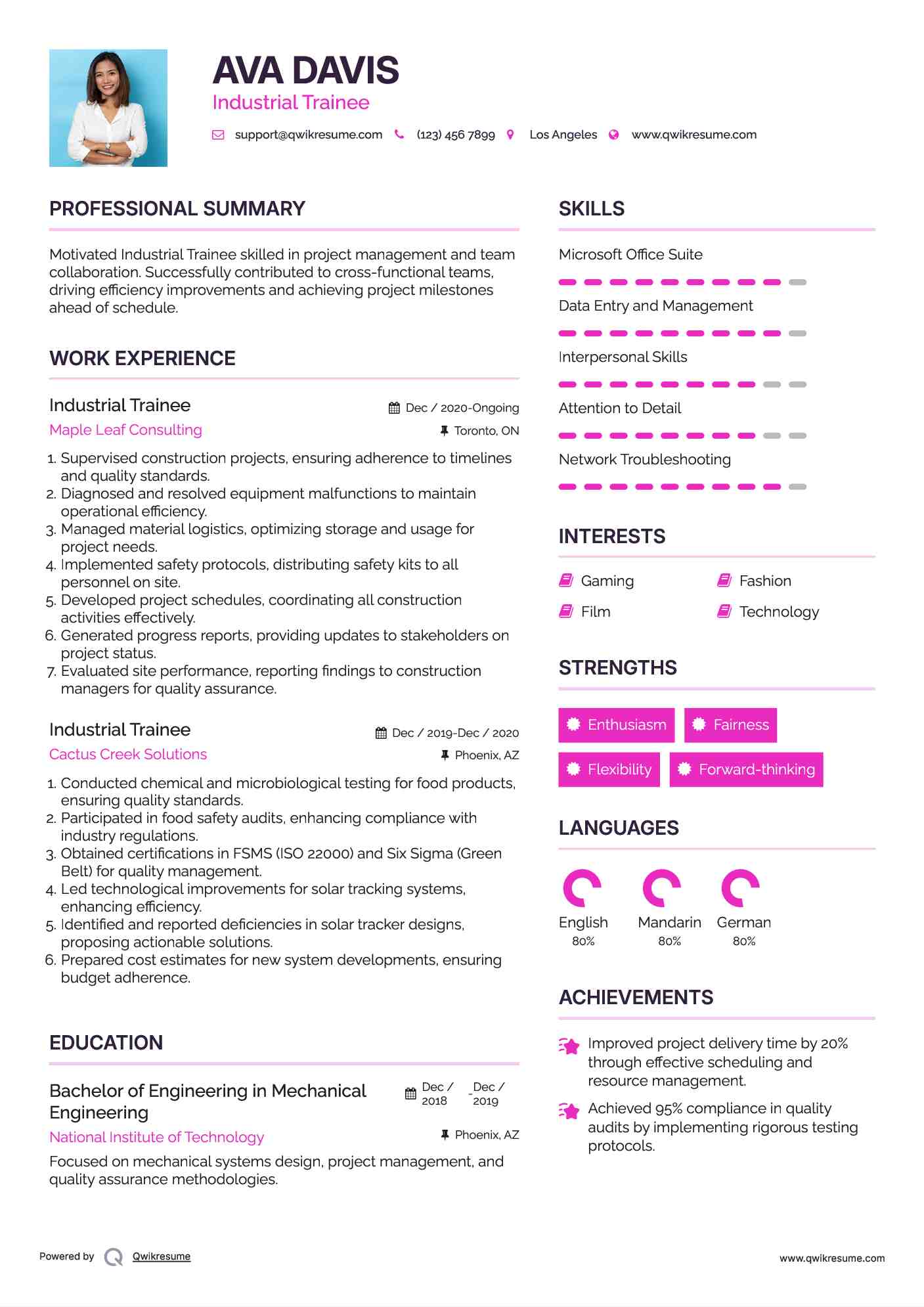

Objective : Motivated Industrial Trainee skilled in project management and team collaboration. Successfully contributed to cross-functional teams, driving efficiency improvements and achieving project milestones ahead of schedule.

Skills : Microsoft Office Suite, Data Entry and Management, Interpersonal Skills, Attention to Detail, Network Troubleshooting

Description :

- Supervised construction projects, ensuring adherence to timelines and quality standards.

- Diagnosed and resolved equipment malfunctions to maintain operational efficiency.

- Managed material logistics, optimizing storage and usage for project needs.

- Implemented safety protocols, distributing safety kits to all personnel on site.

- Developed project schedules, coordinating all construction activities effectively.

- Generated progress reports, providing updates to stakeholders on project status.

- Evaluated site performance, reporting findings to construction managers for quality assurance.

Experience

2-5 Years

Level

Executive

Education

B.E. in ME

Industrial Trainee Resume

Objective : Detail-oriented Industrial Trainee with 2 years of hands-on experience in engineering processes and quality assurance. Proven ability to enhance operational efficiency and contribute to team success in a dynamic environment.

Skills : Project Management, Process Improvement, Technical Communication, Data Analysis, Quality Control

Description :

- Collaborated on the brake system of Linke Hofmann Busch LHB coaches, enhancing safety and performance.

- Implemented ergonomic working methods, boosting workforce efficiency by 10%.

- Maintained diesel locomotive engines, conducting oil viscosity tests and non-destructive testing for quality assurance.

- Proposed team rotations and breaks to reduce injury risks, improving overall worker safety.

- Analyzed cement plant processes, identifying areas for operational improvement.

- Documented preventive measures to enhance machine reliability and competitiveness.

- Recommended design changes for machine parts, increasing productivity and profitability.

Experience

0-2 Years

Level

Entry Level

Education

B.E. Mech

Industrial Trainee Resume

Objective : Detail-oriented Industrial Trainee with hands-on experience in process optimization and quality control. Proven ability to analyze data and implement solutions that enhance productivity and reduce waste in manufacturing environments.

Skills : High-Performance Liquid Chromatography, Dissolution Testing, Fourier Transform Infrared Spectroscopy, Data Analysis, Process Optimization

Description :

- Designed and optimized industrial processes using relational databases like MySQL and PostgreSQL, enhancing data retrieval efficiency.

- Developed a user-friendly interface for real-time monitoring of industrial operations, improving data accessibility.

- Utilized data visualization tools to present insights from operational data, aiding decision-making for process improvements.

- Conducted thorough analysis of operational data to identify trends and areas for optimization, leading to increased productivity.

- Collaborated with cross-functional teams to implement process improvements, achieving a 15% reduction in operational costs.

- Maintained compliance with industry standards and best practices, ensuring high-quality outputs.

- Provided training and support to team members on new technologies and processes, fostering a culture of continuous improvement.

Experience

0-2 Years

Level

Entry Level

Education

B.E.

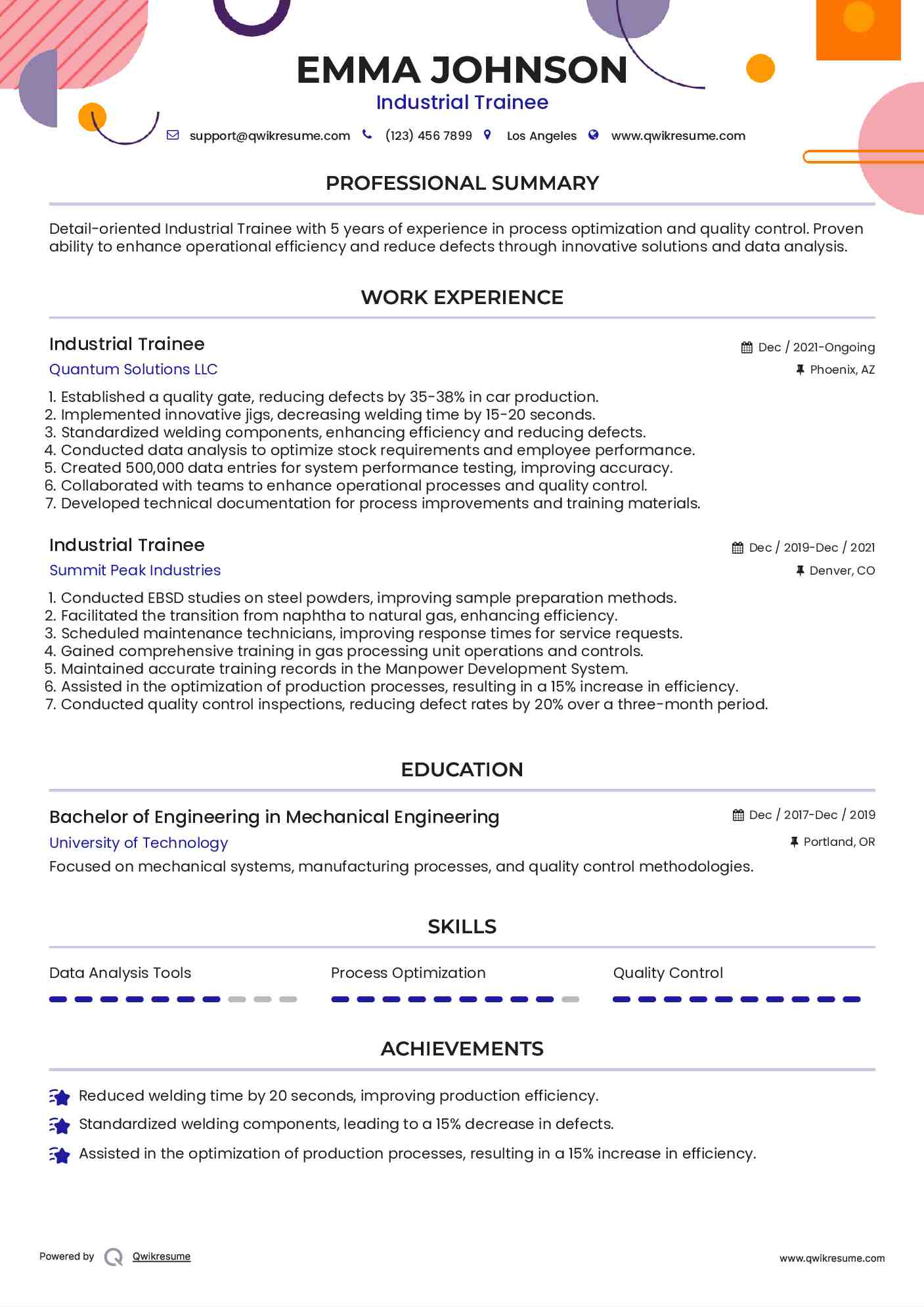

Industrial Trainee Resume

Objective : Detail-oriented Industrial Trainee with 5 years of experience in process optimization and quality control. Proven ability to enhance operational efficiency and reduce defects through innovative solutions and data analysis.

Skills : Data Analysis Tools, Process Optimization, Quality Control

Description :

- Established a quality gate, reducing defects by 35-38% in car production.

- Implemented innovative jigs, decreasing welding time by 15-20 seconds.

- Standardized welding components, enhancing efficiency and reducing defects.

- Conducted data analysis to optimize stock requirements and employee performance.

- Created 500,000 data entries for system performance testing, improving accuracy.

- Collaborated with teams to enhance operational processes and quality control.

- Developed technical documentation for process improvements and training materials.

Experience

2-5 Years

Level

Executive

Education

B.Eng. ME

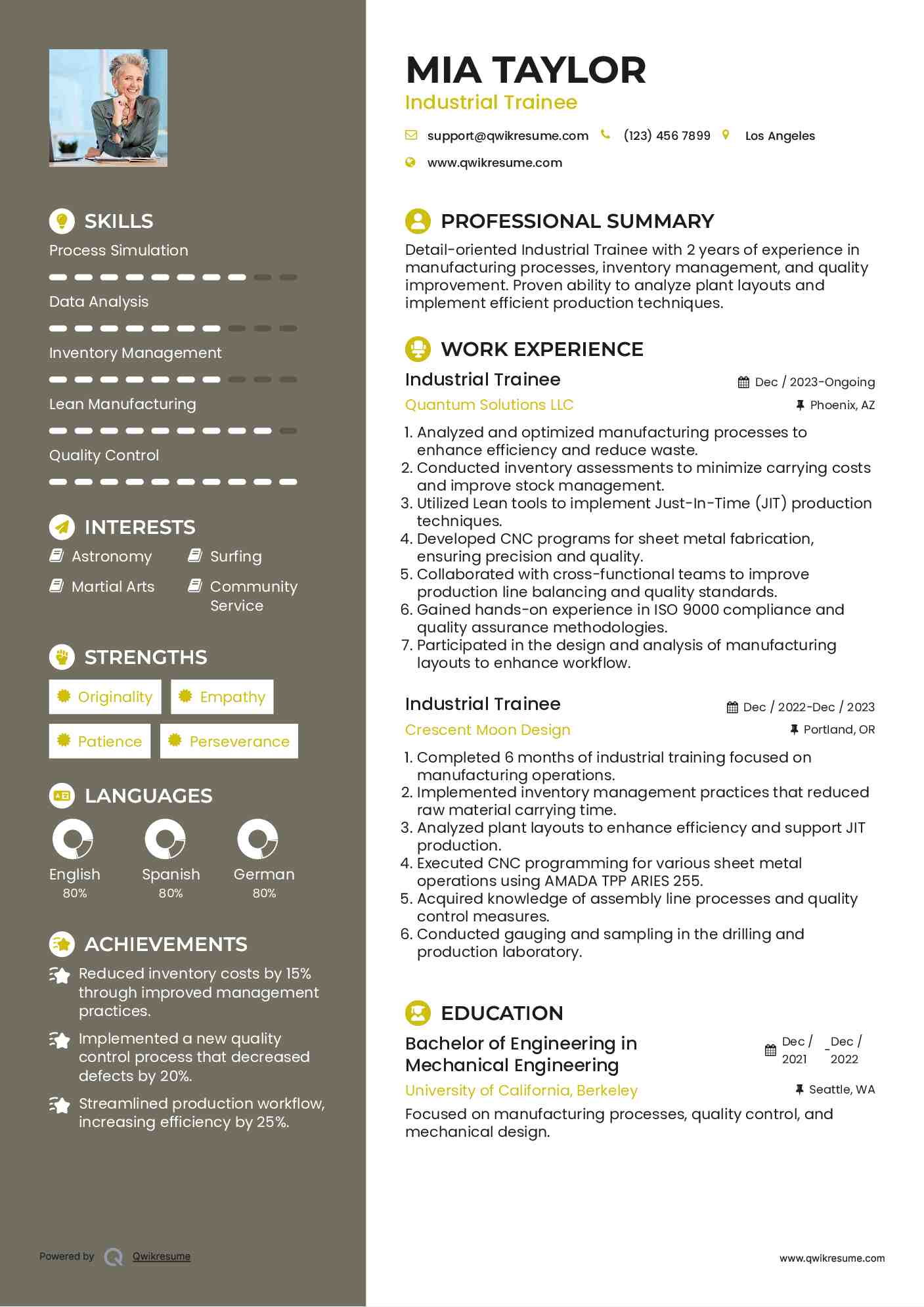

Industrial Trainee Resume

Objective : Detail-oriented Industrial Trainee with 2 years of experience in manufacturing processes, inventory management, and quality improvement. Proven ability to analyze plant layouts and implement efficient production techniques.

Skills : Process Simulation, Data Analysis, Inventory Management, Lean Manufacturing, Quality Control

Description :

- Analyzed and optimized manufacturing processes to enhance efficiency and reduce waste.

- Conducted inventory assessments to minimize carrying costs and improve stock management.

- Utilized Lean tools to implement Just-In-Time (JIT) production techniques.

- Developed CNC programs for sheet metal fabrication, ensuring precision and quality.

- Collaborated with cross-functional teams to improve production line balancing and quality standards.

- Gained hands-on experience in ISO 9000 compliance and quality assurance methodologies.

- Participated in the design and analysis of manufacturing layouts to enhance workflow.

Experience

0-2 Years

Level

Entry Level

Education

B.E. Mech.

Industrial Trainee Resume

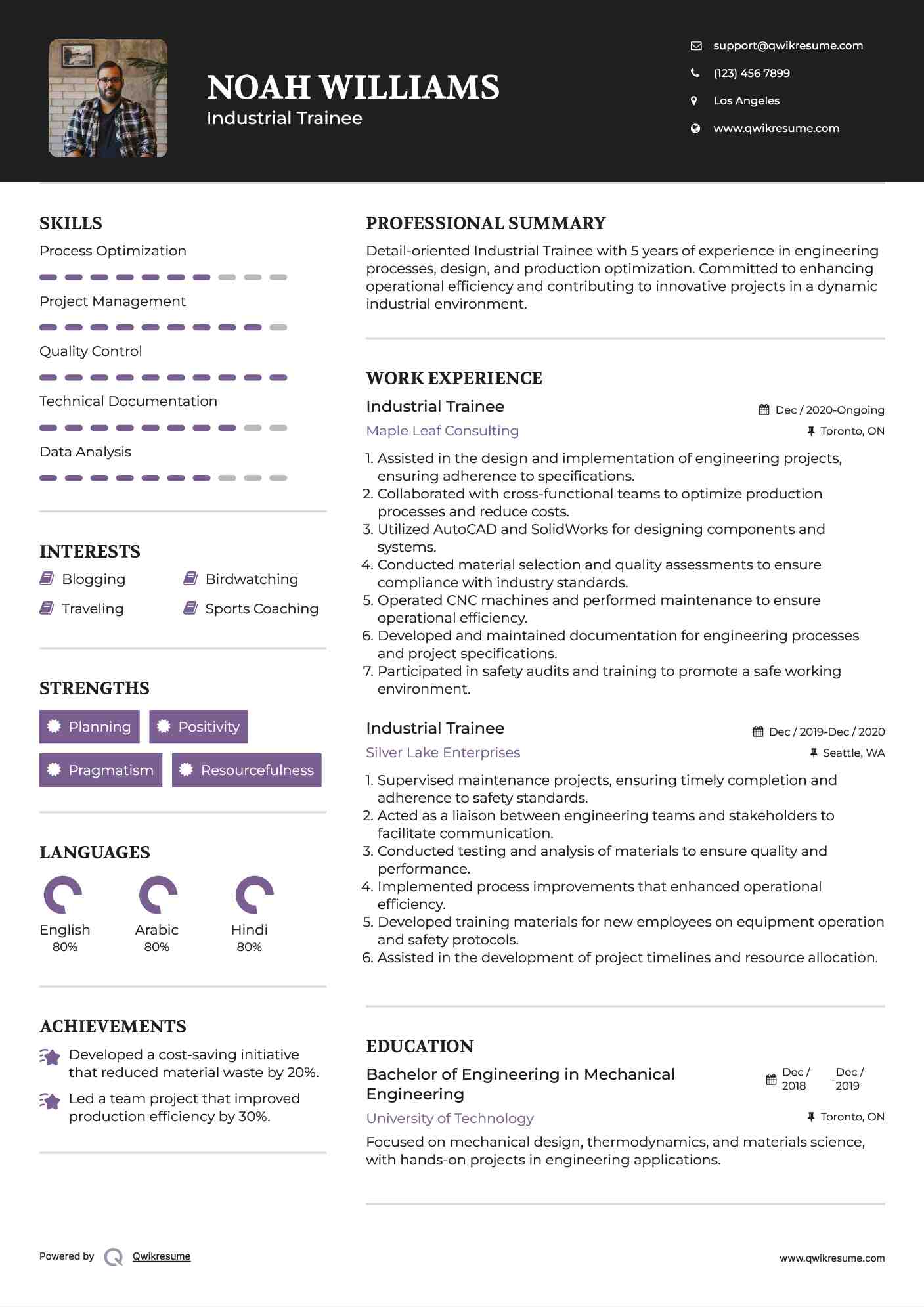

Objective : Detail-oriented Industrial Trainee with 5 years of experience in engineering processes, design, and production optimization. Committed to enhancing operational efficiency and contributing to innovative projects in a dynamic industrial environment.

Skills : Process Optimization, Project Management, Quality Control, Technical Documentation, Data Analysis

Description :

- Assisted in the design and implementation of engineering projects, ensuring adherence to specifications.

- Collaborated with cross-functional teams to optimize production processes and reduce costs.

- Utilized AutoCAD and SolidWorks for designing components and systems.

- Conducted material selection and quality assessments to ensure compliance with industry standards.

- Operated CNC machines and performed maintenance to ensure operational efficiency.

- Developed and maintained documentation for engineering processes and project specifications.

- Participated in safety audits and training to promote a safe working environment.

Experience

2-5 Years

Level

Executive

Education

B.Eng. Mech. Eng.

Industrial Trainee Resume

Objective : Results-driven Industrial Trainee with a strong foundation in engineering principles. Demonstrated expertise in conducting experiments and analyzing results to support product development and innovation in a fast-paced industrial setting.

Skills : Process Improvement, Quality Control, Data Analysis, Process Optimization, Inventory Management

Description :

- Monitored and analyzed workflow and production processes to identify areas for improvement.

- Designed and implemented quality improvement projects, enhancing efficiency across production lines.

- Collaborated with the quality assurance team to develop guidelines that improved operational standards.

- Managed inventory levels, liaising with vendors to ensure timely stock replenishment.

- Maintained accurate documentation for production processes, ensuring compliance with industry standards.

- Applied mechanical principles to operate and maintain equipment effectively, ensuring optimal performance.

- Reviewed and adhered to production standard operating procedures to ensure quality and safety.

Experience

2-5 Years

Level

Executive

Education

BSc IE

Industrial Trainee Resume

Objective : Detail-oriented Industrial Trainee with 5 years of experience in optimizing manufacturing processes, enhancing productivity, and implementing cost-effective solutions. Proven ability to analyze data and improve operational efficiency.

Skills : Client Relations, Process Optimization, Data Analysis, Inventory Management, Quality Control

Description :

- Designed and optimized workshop layouts to enhance tool and equipment productivity.

- Conducted research on new climate control products and managed inventory effectively.

- Redesigned workshop workflow, increasing press machine productivity by 70%.

- Minimized equipment waste by 5% through precise force recalculations for reshaping plates.

- Proposed cost-effective design solutions for new warehouse construction to management.

- Expanded client base by developing leads and meeting client requirements.

- Applied structural and material sciences engineering concepts in practical settings.

Experience

2-5 Years

Level

Executive

Education

B.E. Mechanical