Injection Molding Operator Resume

Headline : An experienced Injection Molding Operator. Maintain high level of quality and consistency work. Use hard and soft problem-solving skills to correct issues. Ability to follow instructions, and to work in a fast pace environment. Have an Injection Molding machine operation experience.

Skills : Manufacturing, Operation Control, Quality Control Analysis, MS Office.

Description :

- Kept work area clean and clean for safety purposes according to company policy.

- Managed injection molding machine during its operation and evaluated the quality of materials produced.

- Operated the molding machine packed the parts feed the machine with plastic feed count each part before packing the cleaning machine before turning again.

- Ran up to 3 machines nightly making all types of rubber gaskets and seals for underground piping.

- Putting the parts from the injection mold on to the car parts as fast as one could.

- Operated an injection molding machine to produce various plugs on power cords and wiring harnesses.

- Observed machine operations to detect any problems; make necessary adjustments to correct problems.

Experience

5-7 Years

Level

Executive

Education

HS

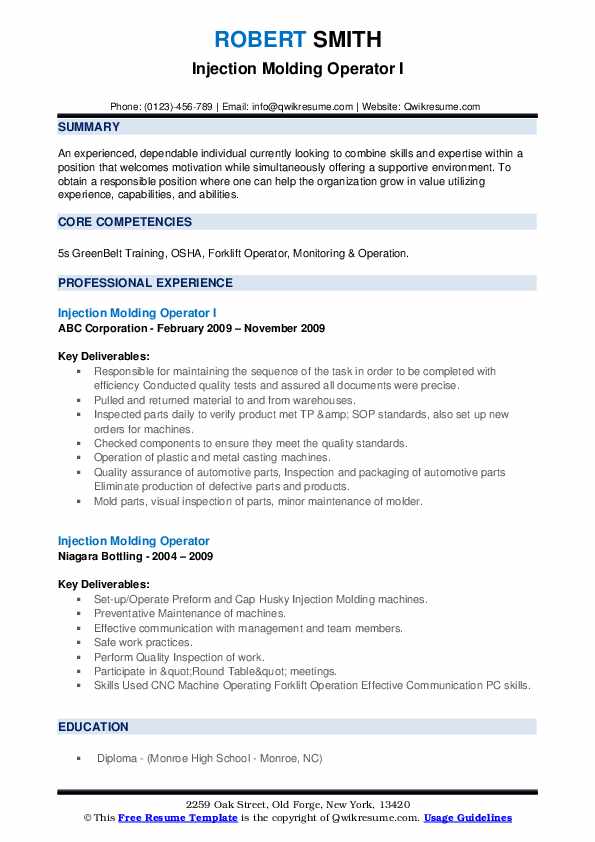

Injection Molding Operator I Resume

Objective : An experienced, dependable individual currently looking to combine skills and expertise within a position that welcomes motivation while simultaneously offering a supportive environment. To obtain a responsible position where one can help the organization grow in value utilizing experience, capabilities, and abilities.

Skills : 5s GreenBelt Training, OSHA, Forklift Operator, Monitoring & Operation.

Description :

- Responsible for maintaining the sequence of the task in order to be completed with efficiency Conducted quality tests and assured all documents were precise.

- Pulled and returned material to and from warehouses.

- Inspected parts daily to verify product met TP & SOP standards, also set up new orders for machines.

- Checked components to ensure they meet the quality standards.

- Operated of plastic and metal casting machines.

- Pressed brake machine operator, load and unload parts, trimmed rubber from parts and inspected parts before boxing.

- Ordered material for each job order, all paperwork, ordering packaging for each job and monitoring material flow.

Experience

2-5 Years

Level

Junior

Education

Diploma

Injection Molding Operator- Temp Resume

Summary : Injection Molding Operator with 8 years of experience is now seeking to obtain a responsible position where one can help the organization grow in value utilizing experience, capabilities, and abilities.

Skills : Customer Service, Phone Etiquette, Computer Skills, Communication Skills, Positive Attitude, Scheduling, Scheduling Appointments, Injection Molding, Patient Care, Fast Learner, Quality Control.

Description :

- Run injection molding machines, purging machines.

- Machined Attendant, filling hoppers, making sure machines were filled with resin.

- Make sure proper jobs were run in order, making sure orders were filled, keeping track of up to 30 employees.

- Tested medical parts to make sure they fell into proper specifications, visual inspections, pressure inspections, dye inspections.

- Setup and operation of injection molding machine including finishing of the product as it came off the machine, assembly of hinged toilet seats, performing quality checks.

- Managed 13 Injection molding presses to include daily and weekly hydraulic maintenance on all presses.

- Performed all hourly quality checks on product and material.

- Maintained all daily, weekly, and monthly reports including payroll.

Experience

7-10 Years

Level

Management

Education

Diploma

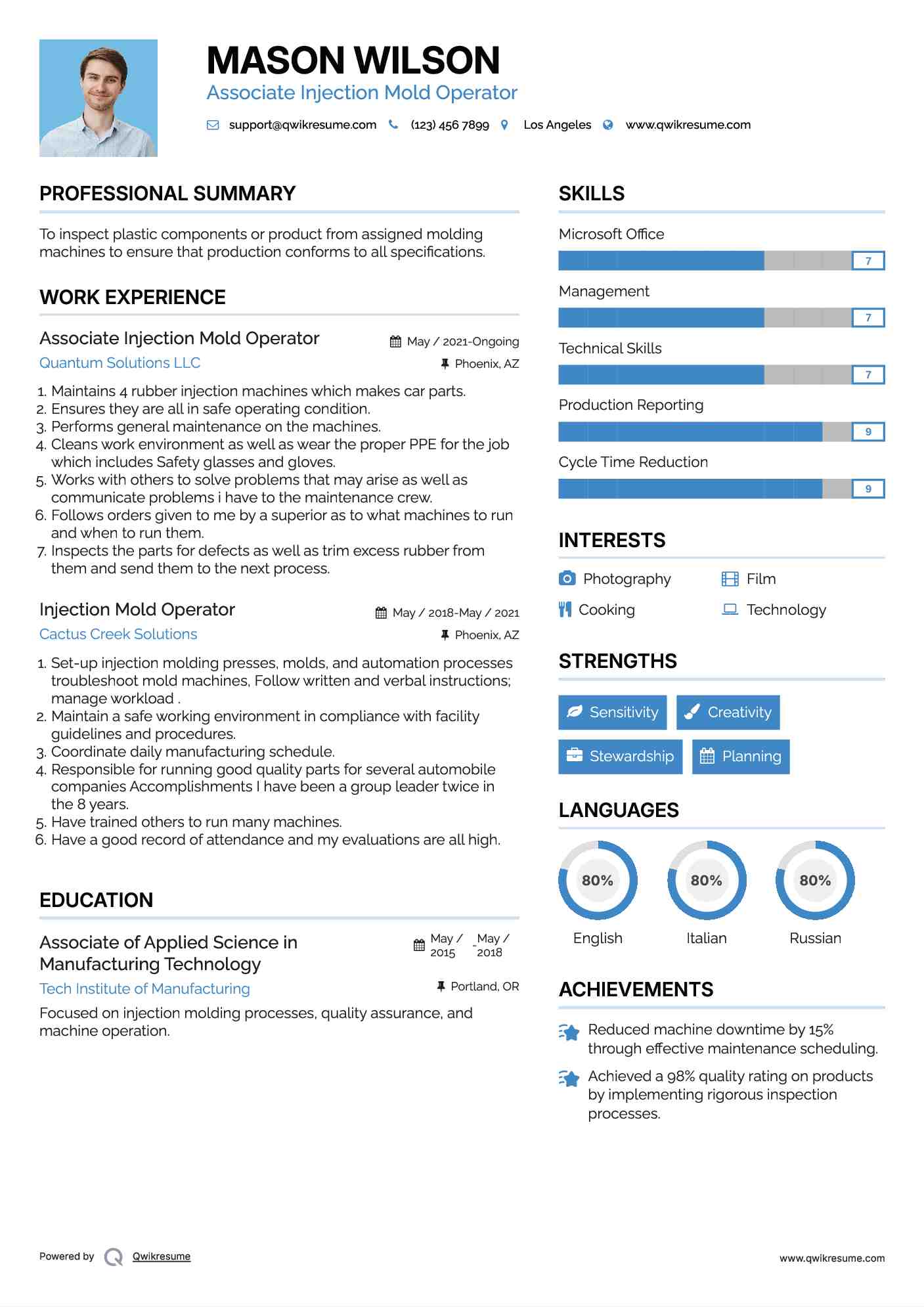

Associate Injection Molding Operator Resume

Objective : An experienced Injection Molding Operator is now seeking to work in a challenging position that would assist your business in achieving growth through maximum use of experience, education, and qualifications, ultimately qualifying for advancement and increased decision-making responsibilities.

Skills : Group Lead, First aid, Forklift Operator, MS Office.

Description :

- Observed continuous operation of automatic machines to ensure that products meet specifications and to detect jams malfunctions making adjustments as necessary.

- Measured and visually inspected products for surface and dimensions defects in order to ensure conformance to specifications using precision measuring tools.

- Setup, operated, tend metal, plastic molding, casting, core making machines to mold cast metal specifications using precision tools.

- Position and secured workplaces on machines and start feeding mechanisms.

- Remove finished cured products from dying molds using hand tools, air hoses, and other equipment, stamping identifying information on products when necessary.

- Trimed excess material from parts using knives and grind scrap plastic into powder for reuse.

- Observed meters and gauges to verify and record temperature, pressures, and press-cycle times.

- Sprayed, smoked, and coated molds with compounds to lubricate and insulate molds using acetylene torches and sprayers.

Experience

2-5 Years

Level

Junior

Education

HS

Injection Molding Operator III Resume

Objective : A dependable individual with 5 years of experience is currently looking to combine skills and expertise within a position that welcomes motivation while simultaneously offering a supportive environment.

Skills : Cleaning, Communication, Problem Resolution, Strong work ethic, Creativity, Adaptability, Positive attitude, Teamwork, Flexible.

Description :

- Effective communicated with management and team members.

- Handled all Quality Inspection Plans (QIP) to include material analysis which measures moisture in the raw material.

- Worked in a team environment performing the visual and dimensional inspection.

- Performed set-ups adjustments and operated a variety of production equipment.

- Diagnosed malfunctions of sensors for proper drying methods of raw plastic material Performed complete molding process per standard operating procedure.

- Responsible for adjustments to ensure efficiency in standard operating procedures and engineering specifications are followed and maintained.

- Mixed material for molding & checked molding for defects.

- Operated on multiple automatic and manual injection molding machines final quality inspection of all products.

Experience

2-5 Years

Level

Junior

Education

Associate

Assistant Injection Molding Operator Resume

Headline : Seeking to obtain a position as a setup technician supervisor, utilizing extensive knowledge and experience on mold installation and machine set up and operation, as well as material handling, and personnel supervision.

Skills : Forklift Operator, QC Analysis, Critical Thinking, MS Office.

Description :

- Operated horizontal and vertical injection molding machines.

- Inspected molded parts for inconsistencies, damages, and/or defects and ensured the necessary documentation was created or updated and accurate records were furnished as needed.

- Proficiently operated machines in a cleanroom environment.

- Contributed to the training of new molding operators and other manufacturing personnel.

- Accurately and efficiently maintained daily production records and staff scheduling and attendance tracking working hours using workforce timekeeper (KRONOS).

- Created training material and conducted workshops on the 5S workplace organization system.

- Followed all warehouse safety standards and exercised good housekeeping by maintaining area clean and organized.

Experience

5-7 Years

Level

Executive

Education

Diploma

Jr. Injection Molding Operator Resume

Objective : A highly motivated and dependable individual seeking to gain an HVAC technician position with a quality orientated company. Opportunity to utilize skills and experience towards becoming a professional HVAC installer and service technician.

Skills : Forklift Operator, Production and Processing, QA/QC Analysis.

Description :

- Observed machine operation to detect workpiece defects and production figures and malfunctions.

- Stopped machine and report malfunction to team leader.

- Inspected completed compact discs to ensure that the product is manufactured according to specifications.

- Routinely monitor the machine's overall yield and quality of product to reduce scrap.

- Feed work in process compact discs in the coating, metalizing, and/or injection molding machines and ensured that product is manufactured according to specifications.

- Fit stamper to molding machine and setup the machine for optimum quality and throughput.

- Performed minor process troubleshooting on injection molding machines to achieve product quality in conformance to quality standards.

- Tested product quality by performing first-off checks.

Experience

2-5 Years

Level

Junior

Education

HVAC

Injection Molding Operator- Technical Resume

Headline : An energetic self-starter with strong communication skills, work well independently or on a team. Seeking to obtain a responsible position where one can help the organization grow in value utilizing experience, capabilities, and abilities.

Skills : Microsoft Office, Excel, Powerpoint, Microsoft Word, Communications, Warehouse, Customer Service, Machine Operator, Quality Inspector.

Description :

- Inspected or measured finished workpieces to determine conformance to specifications, using measuring instruments such as gauges or micrometers.

- Measured workpieces and layout work, using precision measuring devices.

- Studied blueprints, work orders, or machining instructions to determine product specifications, tool requirements, and operational sequences.

- Activated machine start-up switches to grind, lap, hone, debar, shear, or cut workpieces, according to specifications.

- Computed machine indexings and settings for specified dimensions and base reference points.

- Maintained stocks of machine parts and machining tools.

- Set appropriate stops and guides to specified lengths as indicated by scale, rule or template.

Experience

5-7 Years

Level

Executive

Education

HS

Lead Injection Molding Operator Resume

Summary : Manufacturing professional bringing 9 years in production and fabrication, as well as forklift operation. Results-oriented with excellent interpersonal skills. Hard-working and dedicated injection molding press operator with 6 years in heavy equipment operation.

Skills : Forklift Driver, CPR, Lean Sigma, MS Office.

Description :

- Adjusted machine feed and speed if the machine malfunctioned.

- Examined weld for bead size and other specifications.

- Helped achieve company goals by supporting production workers.

- Developed production tracking and quality control systems, analyzing the production, quality control, maintenance, and other operational reports, to detect production problems.

- Inspected finished products for quality and adherence to customer specifications.

- Adhered to all applicable regulations, policies, and procedures for health, safety, and environmental compliance.

- Calibrated or adjusted equipment to ensure quality production using tools such as calipers, micrometers, height gauges, protractors, and ring gauges.

Experience

7-10 Years

Level

Management

Education

Diploma

Injection Molding Operator-Supervisor Resume

Summary : An experienced professional actively seeking to obtain a leadership position where one can instruct and guide employees while assisting fellow management in growing our business.

Skills : Construction trades, Landscaper.

Description :

- Added/Removed metal bars to the machine to ensure plastic covered the bars to form new products.

- Ran modified injection molding machine that produced scalpels, tweezers, and clamps.

- Ensured metal powders that supplied the machine were suitable for injection.

- Noted and reported scrap defects to management.

- Responsible for operating and tending plastic molding, core making, or casting machines to mold or cast plastic parts or products.

- Removed burrs, sharp edges, rust, and scale from workpieces to prevent malfunction.

- Coordinated and assembled ducts, hoods and other sheet metal products.

Experience

7-10 Years

Level

Management

Education

Diploma

Asst. Injection Mold Operator Resume

Objective : Injection Mold Operator position is responsible for the handling and trimming of basic injection plastic parts in the production of cooler related products that accomplish all standards.

Skills : Manage inventory, MS Office.

Description :

- Operates Injection Molding Machines

- Responsible for visual inspection of production for defects based on Standard. Monitor product for any quality issues.

- Accurately Tracks production and rejects on production form.

- Verifies that equipment is operating properly. Notify Team Lead or Supervisor.

- Adheres to all Safety Practices.

- Participates and supports lean activities.

- Ensures work area meets 5S guidelines.

- Performs product stacking per engineering standards.

- Gets the proper material to the required machines in a safe, productive and efficient manner.

- Maintains acceptable level of housekeeping by 5S standards in the assigned work area. Work areas must be kept free and clear of trash (paper, plastic, cups, bottles, and gloves) or any items which are not necessary to perform work assignment.

Experience

2-5 Years

Level

Junior

Education

Diploma

Associate Injection Mold Operator Resume

Headline : To inspect plastic components or product from assigned molding machines to ensure that production conforms to all specifications.

Skills : Microsoft Office, Management.

Description :

- Maintains 4 rubber injection machines which makes car parts.

- Ensures they are all in safe operating condition.

- Performs general maintenance on the machines.

- Cleans work environment as well as wear the proper PPE for the job which includes Safety glasses and gloves.

- Works with others to solve problems that may arise as well as communicate problems i have to the maintenance crew.

- Follows orders given to me by a superior as to what machines to run and when to run them.

- Inspects the parts for defects as well as trim excess rubber from them and send them to the next process.

Experience

5-7 Years

Level

Executive

Education

Diploma

Injection Mold Operator Resume

Summary : To bring skills and experiences to benefit the company. And to be an ideal employee and valuable team member for proving a strong commitment to working safely.

Skills : Management, MS Office.

Description :

- Operated seven different injection mold machines,

- Handled for six lines, three JSW machines, and the vacuum form department.

- Assembled on two lines; installing cup holders in front right and front left doors.

- Installed foam and tape onto doors.

- Inspected every department except for material handling.

- Cleaned at end of every shift.

- Break reliefs occasionally.

- Ensured that all health and safety guidelines were followed.

- Adhered to all safety protocols and safe work practices to reduce likelihood of injury.

Experience

7-10 Years

Level

Consultant

Education

Technician