Lathe Operator Resume

Summary : Dedicated Lathe Operator with over 10 years of experience in precision machining and fabrication. Proficient in interpreting blueprints and operating CNC and manual lathes to produce high-quality components.

Skills : Torch Operation, Blueprint Interpretation, CNC Programming, Quality Control

Description :

- Operated CNC and manual lathes to fabricate precision components per specifications.

- Interpreted blueprints and technical drawings to ensure accurate machining.

- Calibrated machines and tools to maintain production quality and efficiency.

- Implemented cost-effective production methods, reducing operational costs.

- Conducted routine maintenance on machines to prevent downtime and ensure safety.

- Collaborated with engineering teams to troubleshoot and resolve production issues.

- Adhered to safety protocols and quality standards throughout the manufacturing process.

Experience

10+ Years

Level

Senior

Education

AAS-MT

Lathe Operator I Resume

Objective : Dedicated Lathe Operator with 5 years of experience in precision machining and metal fabrication. Proficient in operating various lathes, ensuring high-quality production and adherence to safety standards.

Skills : Precision Machining Skills, CNC Programming, Blueprint Reading, Quality Control, Machine Setup

Description :

- Operated CNC and manual lathes to produce precision components with minimal supervision.

- Set up and calibrated machines for optimal performance and accuracy.

- Monitored production processes to ensure adherence to quality standards.

- Performed routine maintenance and troubleshooting on lathe equipment.

- Collaborated with engineering teams to improve machining processes.

- Maintained a clean and safe work environment in compliance with safety regulations.

- Documented production data and maintained accurate records of operations.

Experience

2-5 Years

Level

Junior

Education

AAS-MTT

CNC Lathe Operator Resume

Headline : Dedicated Lathe Operator with 7 years of experience in precision machining. Proficient in interpreting blueprints and optimizing machine settings to achieve high-quality production standards.

Skills : Precision Tools, CNC Programming, Blueprint Interpretation, Quality Control, Machine Maintenance

Description :

- Analyze blueprints and job orders to determine specifications and tooling requirements for machining operations.

- Secure and position metal stock in machines using hoists and hand tools for optimal machining.

- Operate lathes, adjusting controls to maintain precise timing, clearances, and tolerances throughout production cycles.

- Monitor machine performance, making adjustments to ensure adherence to quality standards and specifications.

- Conduct routine maintenance on lathes, ensuring lubrication and operational efficiency are consistently maintained.

- Utilize measuring tools such as calipers and micrometers to verify dimensions and tolerances of finished products.

- Collaborate with engineering teams to refine machining processes and improve production workflows.

Experience

5-7 Years

Level

Executive

Education

AAS-MT

Lathe Operator II Resume

Headline : Detail-oriented Lathe Operator with 7 years of experience in precision machining. Proven ability to operate various lathes, ensuring high-quality production and adherence to specifications. Committed to safety and continuous improvement.

Skills : CNC Machining, Blueprint Reading, Quality Control, Tool Setup, Machining Techniques

Description :

- Measure workpieces for conformance to specifications using precision tools like micrometers and calipers.

- Inspect completed parts for defects and categorize them based on flaws.

- Interpret work orders to determine specifications, materials, and tolerances.

- Load materials into machines and set up for production runs.

- Operate lathes to cut, shape, and finish metal and plastic components.

- Monitor machine operations, adjusting settings to maintain product quality.

- Install and align cutting tools and fixtures to ensure accurate machining.

Experience

5-7 Years

Level

Executive

Education

AAS Machine Tech

Lathe Operator-Temp Resume

Headline : Detail-oriented Lathe Operator with 7 years of experience in precision machining. Proven track record in optimizing production processes, ensuring quality standards, and maintaining equipment for maximum efficiency.

Skills : CNC Programming, Precision Measurement, Blueprint Reading, Tool Selection, Quality Control

Description :

- Adjust machine controls and change tool settings to maintain precise dimensions within specified tolerances.

- Set cutting speeds, depths, and feed rates, positioning tools accurately in relation to workpieces.

- Start lathe machines and monitor operations to ensure adherence to specifications and quality standards.

- Select appropriate cutting tools and tooling instructions based on specifications and material properties.

- Replace worn tools and sharpen cutting tools using grinders to maintain optimal performance.

- Manually adjust tool holders or engage automatic feeding mechanisms for efficient machining.

- Direct coolant flow to work areas to enhance machining processes and tool longevity.

Experience

5-7 Years

Level

Executive

Education

AAS-MT

Associate Lathe Operator Resume

Objective : Dedicated Lathe Operator with 5 years of experience in precision machining and quality control. Proven ability to operate and maintain lathes, ensuring high-quality production and adherence to safety standards.

Skills : Machining Skills, CNC Operation, Blueprint Reading, Quality Assurance

Description :

- Operated CNC lathes to produce precision components, adhering to strict specifications and tolerances.

- Performed routine maintenance and troubleshooting to ensure optimal machine performance.

- Conducted quality inspections using calipers and gauges to verify dimensions and surface finishes.

- Set up machines for various production runs, including tool changes and adjustments.

- Maintained a clean and organized workspace, following all safety protocols.

- Collaborated with engineering to improve machining processes and reduce waste.

- Documented production data and quality checks to maintain compliance with industry standards.

Experience

2-5 Years

Level

Junior

Education

AAS Machine Tech

Lathe Operator II Resume

Summary : Dedicated Lathe Operator with 10 years of experience in precision machining. Proficient in operating various lathes and ensuring high-quality production standards. Seeking to leverage expertise in a challenging role to drive operational excellence.

Skills : Machine Maintenance, Precision Measurement, CNC Programming, Quality Control, Tool Calibration

Description :

- Conducted thorough inspections of workpieces using gauges and micrometers to ensure compliance with specifications.

- Monitored machine operations for unusual sounds, adjusting settings to maintain optimal performance.

- Utilized hoists and cranes to safely lift and position workpieces for machining.

- Ensured proper lubrication and cooling of workpieces during machining to prevent overheating.

- Collaborated with supervisors to troubleshoot machine malfunctions and resolve production issues efficiently.

- Maintained a clean and organized workspace to promote safety and efficiency.

- Documented production data and machine settings for quality assurance and process improvement.

Experience

7-10 Years

Level

Management

Education

AAS Machine Tech

Jr. Lathe Operator Resume

Objective : Detail-oriented Lathe Operator with 5 years of experience in precision machining. Proficient in operating lathes, performing quality checks, and ensuring adherence to specifications. Committed to maintaining high production standards and safety protocols.

Skills : Precision Welding, CNC Machine Operation, Industrial Equipment Operation, Lathe Setup, Blueprint Reading

Description :

- Operated CNC and manual lathes, ensuring optimal product flow and conducting hourly quality checks.

- Adjusted programs and performed tool changes to maintain production efficiency.

- Utilized precision gauges to verify specifications of finished components.

- Managed multiple tasks simultaneously, consistently meeting production targets.

- Monitored machine operations and control panel displays, identifying and resolving malfunctions.

- Loaded finished products onto conveyor systems for efficient processing.

- Maintained a clean and safe work environment, adhering to all safety protocols.

Experience

2-5 Years

Level

Junior

Education

AAS-MT

Lathe Operator-Part Time Resume

Summary : Detail-oriented Lathe Operator with 10 years of experience in precision machining and equipment repair. Proven track record in optimizing processes and ensuring high-quality standards through meticulous attention to detail.

Skills : CNC Machining, Blueprint Interpretation, Quality Control, Tool Calibration, Machining Techniques

Description :

- Accurately measured and marked dimensions and reference points for precision machining.

- Utilized measuring instruments to ensure compliance with strict specifications.

- Dismantled, inspected, and repaired components to maintain operational efficiency.

- Trained and mentored apprentices, fostering skill development and safety practices.

- Fabricated tools, jigs, and fixtures to meet specific manufacturing requirements.

- Indicated proper dimensions on materials for accurate machining processes.

- Calculated and set controls to regulate machining factors, ensuring optimal performance.

Experience

7-10 Years

Level

Management

Education

AAS-MTT

Executive Lathe Operator Resume

Objective : Detail-oriented Lathe Operator with 2 years of experience in precision machining. Proficient in interpreting blueprints and ensuring quality control. Committed to maintaining a safe and efficient work environment.

Skills : Precision Machining, Blueprint Interpretation, Quality Control, Machine Setup

Description :

- Operate and maintain multiple lathes to ensure high-quality production.

- Interpret technical drawings and specifications to produce precise components.

- Utilize gauges and calipers for accurate measurements and quality assurance.

- Adhere to safety protocols to maintain a secure working environment.

- Monitor machine performance and troubleshoot issues to minimize downtime.

- Collaborate with team members to meet production targets efficiently.

- Document production data and maintain accurate records for quality control.

Experience

0-2 Years

Level

Entry Level

Education

AAS Machine Tech

Sr. Lathe Operator Resume

Objective : Detail-oriented Lathe Operator with 2 years of experience in precision machining. Proficient in setting up and operating CNC and manual lathes, ensuring high-quality production and adherence to specifications.

Skills : Precision Machining, CNC Programming, Quality Control, Blueprint Reading, Lathe Setup

Description :

- Interpreted technical drawings to determine dimensions and tolerances for machining operations.

- Initiated production of precision components, ensuring adherence to specifications.

- Optimized lathe programs to achieve tight tolerances and improve production efficiency.

- Troubleshot and resolved machine errors to minimize downtime.

- Coordinated with team members to maintain continuous production flow.

- Set up, operated, and maintained quality standards on CNC and manual lathe machines.

- Conducted final inspections of machined parts for quality assurance.

Experience

0-2 Years

Level

Entry Level

Education

AAS-MT

Assistant Lathe Operator Resume

Headline : Dedicated Lathe Operator with 7 years of experience in precision machining and CNC programming. Proven track record of enhancing production efficiency and maintaining high-quality standards in manufacturing environments.

Skills : CNC Programming, Blueprint Reading, Quality Control, Machine Setup, Tool Maintenance

Description :

- Set up and operated CNC lathes to produce precision components according to specifications.

- Conducted regular maintenance and troubleshooting to minimize machine downtime.

- Collaborated with quality control to ensure all parts met stringent quality standards.

- Adjusted machine settings based on production requirements and quality feedback.

- Documented production data and maintained accurate records for efficiency tracking.

- Trained new operators on machine operation and safety protocols.

- Implemented process improvements that enhanced production efficiency by 15%.

Experience

5-7 Years

Level

Executive

Education

AAS Machine Tech

CNC Auto Lathe Operator Resume

Objective : Detail-oriented Lathe Operator with 2 years of experience in CNC machining and precision manufacturing. Proven ability to produce high-quality components while adhering to safety and quality standards.

Skills : CNC Programming, CNC Lathe Operation, Blueprint Interpretation, Quality Control, Machine Setup

Description :

- Operated CNC lathe machines to produce precision parts according to specifications.

- Programmed and set up machines, ensuring optimal performance and accuracy.

- Monitored production processes, making adjustments to maintain quality standards.

- Conducted quality checks and inspections to ensure compliance with blueprints.

- Maintained detailed records of production metrics and machine performance.

- Collaborated with team members to improve workflow and efficiency.

- Trained new operators on machine operation and safety protocols.

Experience

0-2 Years

Level

Entry Level

Education

AAS Machine Tech

Lathe Operator Resume

Objective : Dedicated Lathe Operator with over 5 years of experience in precision machining and production. Proficient in operating various lathes and ensuring quality control. Committed to optimizing processes and enhancing productivity.

Skills : Lathe Operator, Precision Machining, Blueprint Reading, Quality Control, CNC Programming

Description :

- Set up and operated lathes to produce precision parts according to specifications.

- Monitored machining processes to ensure adherence to quality standards.

- Performed routine maintenance on lathes to ensure optimal performance.

- Trained and mentored junior operators on best practices and safety protocols.

- Conducted inspections of finished products to verify conformance to specifications.

- Collaborated with engineering to troubleshoot and resolve machining issues.

- Maintained accurate records of production and machine performance.

Experience

2-5 Years

Level

Junior

Education

AAS-MT

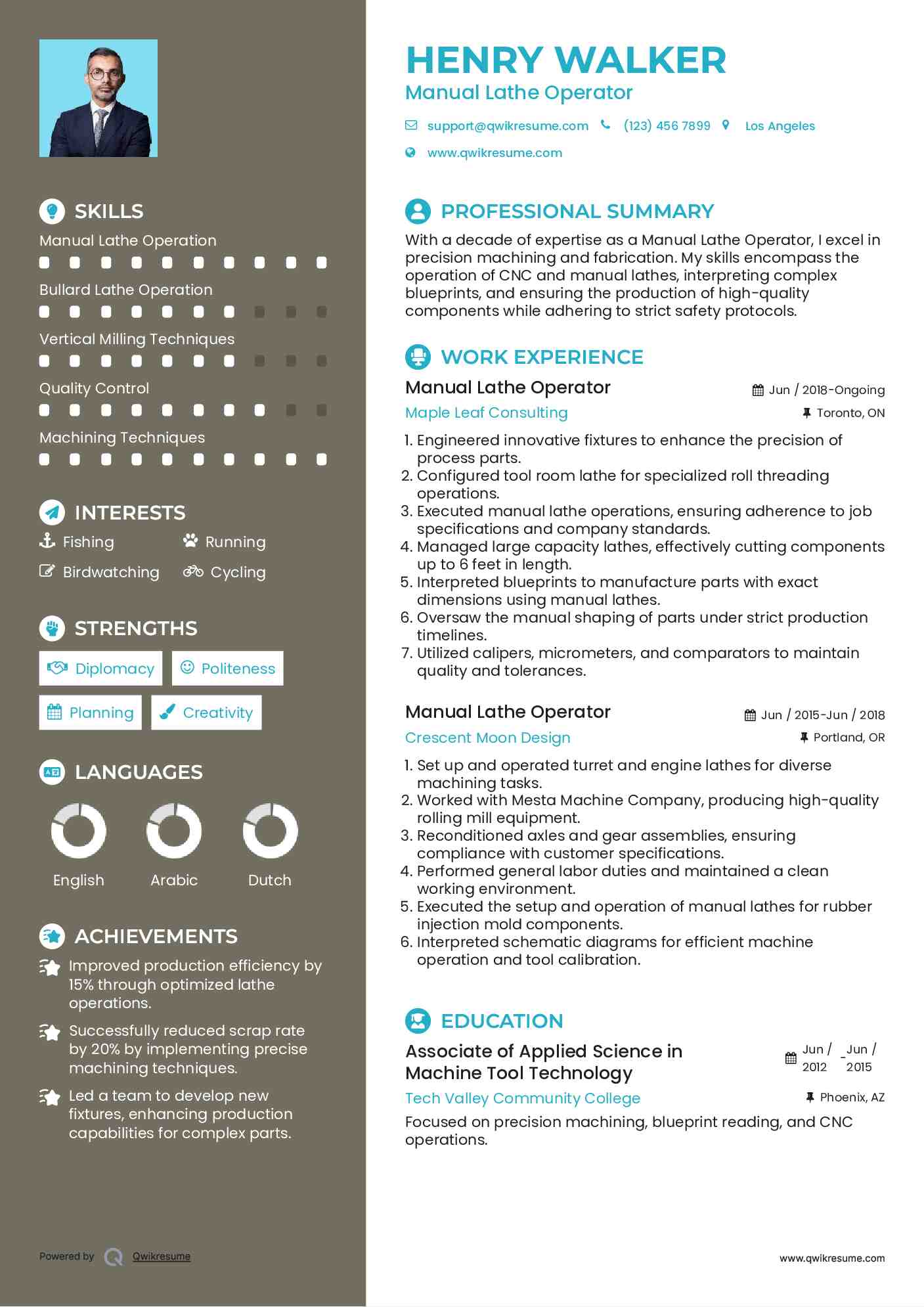

Manual Lathe Operator Resume

Objective : Self-motivated Machinist determined to produce high quality parts per blueprint specifications with the willingness, drive and passion to learn and excel in the machining industry. Ensuring speeds, feeds, and tooling is correct for material being processed in order to maximize machine efficiency. Setting up and operating at least 2 types of CNC equipment (i.e. lathe & mill). Determining and may editing programs to ensure proper radius, contour, and angle measurements.

Skills : Planning, Editing, Loading.

Description :

- Examined blueprints prior to machine operation to ensure the proper machine set up and tooling was acquired for each different job.

- Determined cutting feeds and speeds per each job.

- Measured work piece with precision measuring tools such as, outside, inside, and depth micrometers.

- Used various types of vernier calipers.

- Machined parts to specifications primarily using lathes, but also using vertical and horizontal milling machines.

- Used 20 ton over head or jib crane in conjunction with chains and/or straps to load and unload machines before and after machining.

- Machined fabricated parts, large rough castings, mechanical tubing, long shafting, and other types of materials.

Experience

2-5 Years

Level

Junior

Education

GED

Manual Lathe Operator Resume

Summary : Extensive experience with calipers, ID and OD micrometers, depth, gauges, indicators,and scales proficient with lathes, mills, drill press and, grinders Working knowledge of cnc equipment Superior knowledge in reading drawings and prints and all instructions related to the production of parts knowledge of tool and die design concepts.

Skills : Operating manual lathes, Bullard, Vertical mills, and Small hand tools.

Description :

- Created new fixtures to fit and trim new process parts.

- Set up tool room lathe for roll threading operations.

- Ran manual lathe to cut specific widths in conformance with job cards making sure finished product met company standards.

- Operated large capacity Lathes cutting up to 6 ft.

- Read blueprints and diagrams to to make parts to a specific dimensions have basic knowledge of a manual lathe and its functions.

- In charged of manually shaping parts on strict time schedules.

- Able to preset tools and maintain quality and tolerances with the use of Calipers, micrometers, comparator and other measuring instruments.

Experience

7-10 Years

Level

Management

Education

High School Diploma

Manual Lathe Operator Resume

Summary : To obtain a Manual Lathe Operator position that will utilize my skills, abilities and experience to contribute to the company's success. Performing quality inspection of parts using standard measuring instruments. Performing preventive maintenance on equipment as required. Supporting Continuous Improvement efforts and maintain a safe, clean work area. Completing other duties as assigned.

Skills : Manual Lathes, Machine Parts Holding.

Description :

- Machined safely basic machine operations such as: single point turning, knurling, hole drilling, part marking, and basic threads including tapping and die cutting of threads.

- Trained in any quality systems subscribed to by the facility and able to perform duties or paperwork associated with those systems.

- Trained is done by the supervisor or other qualified person.

- Conferred with supervisors, engineers, production personnel, programmers, or others to resolve machining problems.

- Operate and maintain a manual lathe or mill, under close supervision, to produce a good quality product in a timely fashion as to satisfy demand.

- Trained is done by the supervisor or other qualified person of equivalent experience.

- Learned to grind basic cutting tools and drills.

Experience

7-10 Years

Level

Management

Education

Diploma

Manual Lathe Operator Resume

Summary : To obtain a Manual Lathe Operator is Selecting cutting tools and tooling instructions, according to written specifications or knowledge of metal properties and shop mathematics. Moving tool holders manually or by turning hand wheels, or engage automatic feeding mechanisms to feed tools to and along work pieces. Lifting metal stock or work pieces manually or using hoists, and position and secure them in machines, using fasteners and hand tools. Computing unspecified dimensions and machine settings, using knowledge of metal properties and shop mathematics.

Skills : Planning, Writing, Security.

Description :

- Interpreted a variety of instructions furnished in written, oral, diagram, or schedule form.

- Met ATF & regulatory security requirements.

- Recognized and be discreet with sensitive financial, personnel, and other business related information.

- Worked with people in a harmonious way to accomplish the task assigned to this position.

- Interfaced with both technical and non-technical personnel.

- Provided improvement to processes as required.

- Cranked machines through cycles, stopping to adjust tool positions and machine controls to ensure specified timing, clearances, and tolerances.

Experience

10+ Years

Level

Senior

Education

GED