Manufacturing Quality Engineer Resume

Objective : Dedicated Manufacturing Quality Engineer with 5 years of hands-on experience in quality assurance and process improvement. Adept at utilizing Lean Six Sigma methodologies to enhance product quality and operational efficiency. Proven ability to collaborate effectively with cross-functional teams and implement robust quality management systems to achieve organizational goals.

Skills : Lean Six Sigma, Quality Assurance, Root Cause Analysis, Statistical Process Control

Description :

- Oversaw quality control processes for the largest product line at Autocam Corporation, ensuring adherence to industry standards.

- Collaborated with major clients, including Robert Bosch and Hyundai Motors, to address quality concerns and implement corrective actions.

- Conducted regular quality audits and submitted detailed reports to improve customer satisfaction.

- Implemented new workflows and procedures, significantly enhancing operational efficiency.

- Facilitated training sessions for associates on quality protocols and documentation practices.

- Utilized feedback from manufacturing teams to drive continuous improvement initiatives in weekly meetings.

- Maintained up-to-date knowledge of quality standards and best practices to align with industry advancements.

Experience

2-5 Years

Level

Executive

Education

B.S. IE

Sr. Manufacturing Quality Engineer Resume

Summary : Accomplished Manufacturing Quality Engineer with 10 years of extensive experience in quality assurance and process optimization. Expert in deploying Lean Six Sigma techniques to elevate product standards and enhance operational workflows. Demonstrated success in leading cross-functional teams, implementing quality management systems, and driving continuous improvement initiatives.

Skills : Collaboration and Team Leadership, Root Cause Analysis, Lean Six Sigma Implementation, Quality Management Systems Development, Failure Mode Effects Analysis

Description :

- Engineered high-performance materials and components for the automotive sector, ensuring compliance with rigorous quality standards.

- Oversaw the production of critical components, including power cable harnesses and brake hose products.

- Ensured adherence to product specifications and customer requirements throughout the manufacturing process.

- Facilitated root cause analysis and corrective action planning for customer complaints and returns.

- Trained staff in quality protocols and customer expectations to enhance overall product quality.

- Monitored daily quality metrics and reported key issues to manufacturing leadership for prompt resolution.

- Conducted statistical analysis to identify failure trends and implemented yield improvement strategies.

Experience

10+ Years

Level

Senior

Education

BSIE

Jr. Manufacturing Quality Engineer Resume

Headline : Accomplished Manufacturing Quality Engineer with 7 years of experience in quality control and continuous improvement within the manufacturing sector. Proficient in leveraging Lean Six Sigma methodologies to drive product excellence and elevate operational efficiency. Proven expertise in cross-functional collaboration, developing quality management systems, and implementing robust process validations.

Skills : Quality Assurance, Process Validation, Inspection and Testing, Non-Conformance Reporting, Corrective Action Plans

Description :

- Prepared detailed reports by collecting, analyzing, and summarizing quality-related data, making actionable recommendations.

- Monitored and reported trends in quality metrics to upper management, including complaints and product defects.

- Supported validation of manufacturing processes by utilizing DFMEAs, PFMEAs, and Statistical Process Control methodologies.

- Designed and delivered a GD&T training course for engineering and quality personnel.

- Developed new inspection test methods to ensure compliance with customer specifications.

- Managed a calibration program for inspection and testing equipment to ensure compliance with industry standards.

- Conducted risk assessments and FMEAs for equipment to enhance system validation processes in compliance with ISO 14971.

Experience

5-7 Years

Level

Junior

Education

B.S. in IE

Manufacturing Quality Engineer III Resume

Summary : Seasoned Manufacturing Quality Engineer with a decade of experience in enhancing product quality and optimizing manufacturing processes. Skilled in implementing Lean Six Sigma strategies to reduce waste and improve efficiency. Proven track record of leading quality initiatives and collaborating with diverse teams to ensure compliance with industry standards and drive continuous improvement.

Skills : Lean Six Sigma Green Belt, Supplier Quality Management, Documentation Control, Quality Control Plans, Measurement System Analysis

Description :

- Provided quality engineering expertise, utilizing tools such as root cause analysis and process capability studies to enhance product integrity.

- Established collaborative relationships across all operational levels to effectively monitor quality metrics.

- Conducted in-depth analysis of inspection data, scrap rates, and customer complaints to identify and document continuous improvement initiatives.

- Focused on resolving customer complaints through effective quality management practices.

- Implemented containment strategies and drove root cause corrective actions using 8D methodology.

- Ensured validation and documentation of new and modified equipment and processes in compliance with industry standards.

- Remained current with quality engineering principles and regulatory compliance to uphold corporate policies.

Experience

7-10 Years

Level

Management

Education

B.S. in IE

Manufacturing Quality Engineer II Resume

Objective : Accomplished Manufacturing Quality Engineer with 5 years of experience in quality control and process enhancement. Skilled in applying Six Sigma principles to improve product reliability and operational performance. Demonstrated success in fostering collaboration among teams to implement effective quality management practices and drive continuous improvement initiatives.

Skills : Quality Control Techniques, Manufacturing Process Improvement, Statistical Process Control, Product Lifecycle Management, Technical Problem Solving

Description :

- Coordinated and managed supplier quality issues, serving as the primary contact for BOPs from second-tier vendors.

- Implemented quality assurance processes, achieving a 15% reduction in loading times through Kaizen methodologies.

- Reduced machine downtime by 20% by optimizing maintenance schedules and improving production workflows.

- Conducted statistical process control (SPC) and root cause analysis to address burr defects in cold forging processes.

- Acted as a liaison between customers and production teams to resolve quality-related inquiries effectively.

- Created and maintained Material Safety Data Sheets (MSDS) to ensure compliance with safety regulations.

- Developed and refined adhesive processes to enhance product reliability and quality control.

Experience

2-5 Years

Level

Executive

Education

B.S. IE

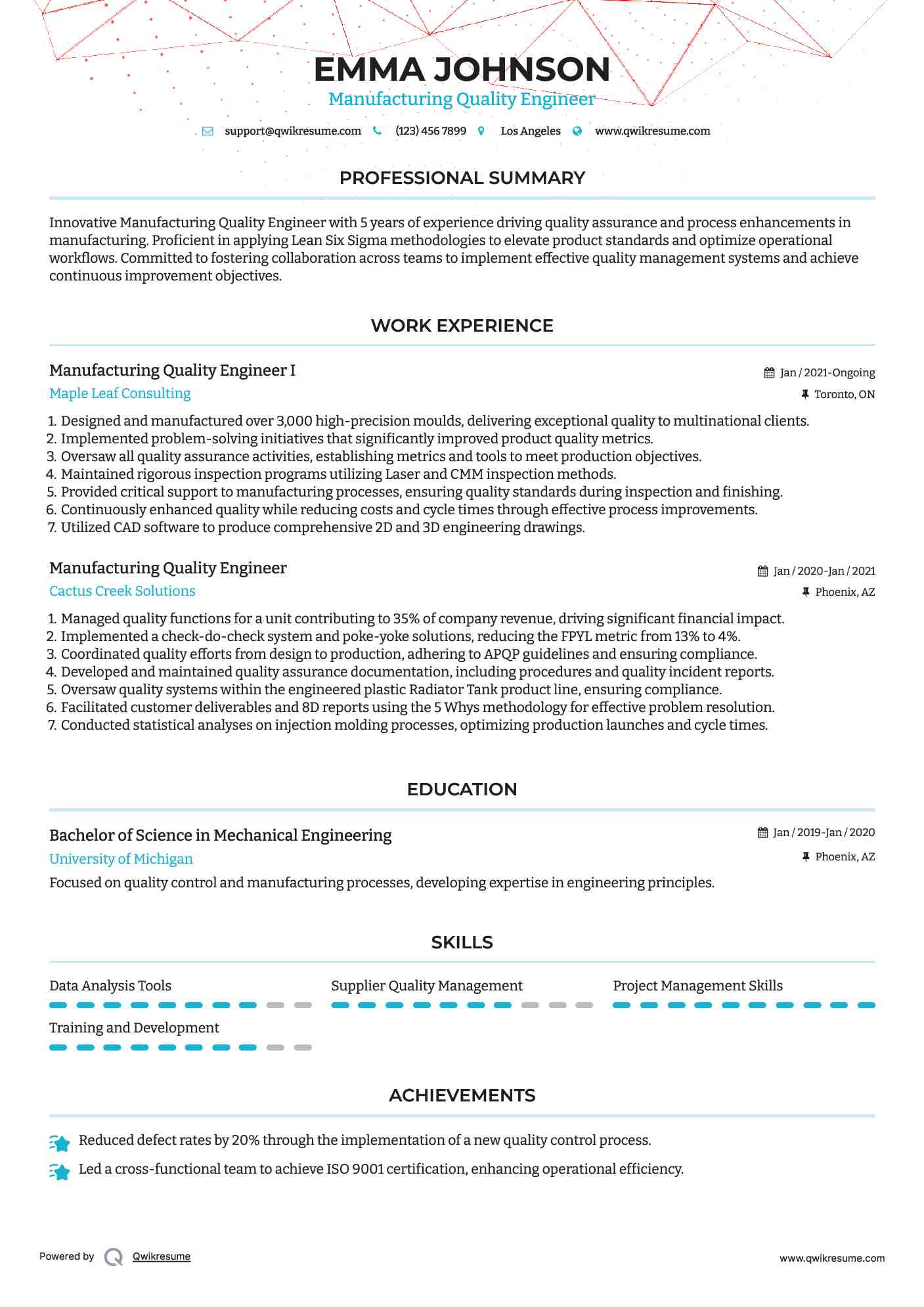

Manufacturing Quality Engineer I Resume

Objective : Innovative Manufacturing Quality Engineer with 5 years of experience driving quality assurance and process enhancements in manufacturing. Proficient in applying Lean Six Sigma methodologies to elevate product standards and optimize operational workflows. Committed to fostering collaboration across teams to implement effective quality management systems and achieve continuous improvement objectives.

Skills : Data Analysis Tools, Supplier Quality Management, Project Management Skills, Training and Development

Description :

- Designed and manufactured over 3,000 high-precision moulds, delivering exceptional quality to multinational clients.

- Implemented problem-solving initiatives that significantly improved product quality metrics.

- Oversaw all quality assurance activities, establishing metrics and tools to meet production objectives.

- Maintained rigorous inspection programs utilizing Laser and CMM inspection methods.

- Provided critical support to manufacturing processes, ensuring quality standards during inspection and finishing.

- Continuously enhanced quality while reducing costs and cycle times through effective process improvements.

- Utilized CAD software to produce comprehensive 2D and 3D engineering drawings.

Experience

2-5 Years

Level

Executive

Education

B.S. Mech. Eng.

Manufacturing Quality Engineer/Technician Resume

Objective : Results-driven Manufacturing Quality Engineer skilled in ISO 9001 standards and Six Sigma methodologies. Successfully led cross-functional teams to enhance product quality, achieving a 25% reduction in non-conformance reports over two years.

Skills : VBA Programming, Process Capability Analysis, Root Cause Corrective Action, Quality Improvement Initiatives, Cost Reduction Strategies

Description :

- Maintained and enhanced quality control processes for CLASS 3 medical devices, ensuring compliance with industry standards.

- Utilized KAIZEN principles to identify and eliminate recurring production issues, leading to significant efficiency gains.

- Assessed current manufacturing performance metrics and established critical-to-quality (CTQ) parameters for process improvements.

- Developed and implemented control plans to address identified quality issues and enhance product reliability.

- Conducted PDCA cycles, CAPA actions, and A3 problem-solving reports to address assembly line challenges.

- Reviewed and validated control plans to ensure alignment with process requirements across all operational areas.

- Redesigned work cell layouts to boost operator productivity and optimize workflow efficiency.

Experience

2-5 Years

Level

Executive

Education

BSE

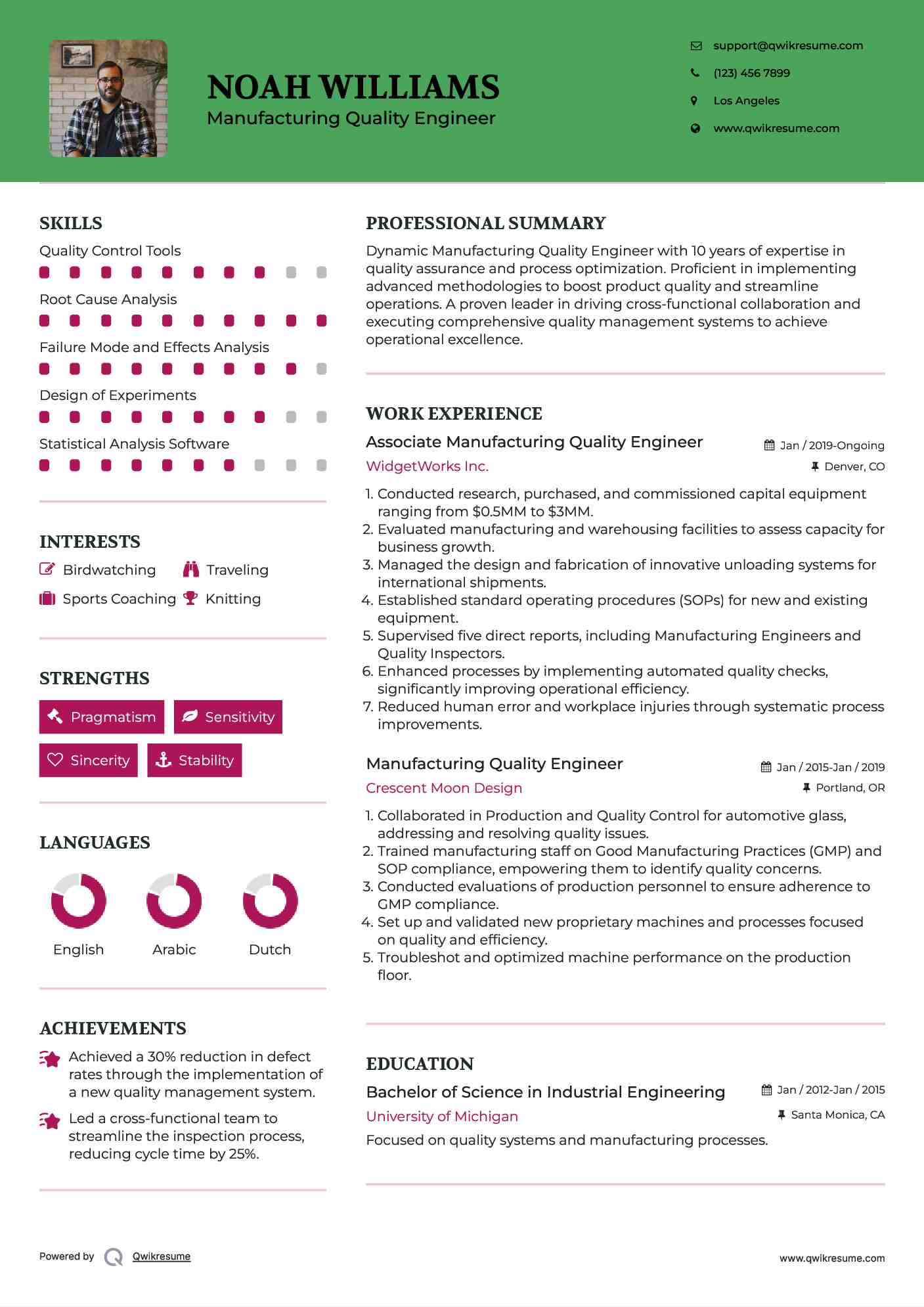

Associate Manufacturing Quality Engineer Resume

Summary : Dynamic Manufacturing Quality Engineer with 10 years of expertise in quality assurance and process optimization. Proficient in implementing advanced methodologies to boost product quality and streamline operations. A proven leader in driving cross-functional collaboration and executing comprehensive quality management systems to achieve operational excellence.

Skills : Quality Control Tools, Root Cause Analysis, Failure Mode and Effects Analysis, Design of Experiments, Statistical Analysis Software

Description :

- Conducted research, purchased, and commissioned capital equipment ranging from $0.5MM to $3MM.

- Evaluated manufacturing and warehousing facilities to assess capacity for business growth.

- Managed the design and fabrication of innovative unloading systems for international shipments.

- Established standard operating procedures (SOPs) for new and existing equipment.

- Supervised five direct reports, including Manufacturing Engineers and Quality Inspectors.

- Enhanced processes by implementing automated quality checks, significantly improving operational efficiency.

- Reduced human error and workplace injuries through systematic process improvements.

Experience

10+ Years

Level

Senior

Education

B.S. IE

Assistant Manufacturing Quality Engineer Resume

Objective : Dedicated Manufacturing Quality Engineer with expertise in statistical process control and quality audits. Instrumental in streamlining inspection processes, resulting in a 40% increase in efficiency and a significant boost in customer satisfaction.

Skills : Quality Control Analysis, Statistical Process Control, Root Cause Analysis, Data Analysis and Reporting, Process Optimization

Description :

- Provided quality engineering support for vacuum thermal processing and powder coating operations.

- Conducted temperature surveys ensuring uniform heating in vacuum furnaces.

- Analyzed heat-treatment cycle data to refine process parameters.

- Implemented changes to enhance the metallurgical properties of high-speed steel.

- Performed preventive maintenance on thermal processing units, optimizing operational reliability.

- Collaborated with cross-functional teams on a $16 million plant expansion project, ensuring design verification and equipment validation.

- Collected and analyzed data to improve overall equipment effectiveness and production efficiency.

Experience

2-5 Years

Level

Executive

Education

B.S. in ME

Manufacturing Quality Engineer Resume

Summary : Accomplished Manufacturing Quality Engineer with a decade of experience in quality assurance and process enhancement. Specializes in utilizing advanced methodologies to elevate product quality, optimize processes, and ensure compliance. Proven success in leading teams to implement effective quality management systems, driving continuous improvement, and fostering a culture of excellence.

Skills : Data Analysis, Cross-Functional Collaboration, Quality Risk Assessment, Supplier Auditing Skills, Technical Documentation

Description :

- Conducted evaluations and compliance audits in manufacturing settings to ensure adherence to cGMP standards.

- Performed real-time batch record reviews to uphold product integrity and quality.

- Created, reviewed, and revised Standard Operating Procedures (SOPs) while assisting with effective root cause investigations.

- Executed comprehensive data analysis to identify trends and areas for improvement.

- Identified corrective and preventive actions, implementing continuous process improvements across operations.

- Provided quality oversight on the shop floor, addressing manufacturing deviations in real-time.

- Monitored compliance in Aseptic and Terminally Sterile Filling areas, ensuring all procedures align with SOPs and regulatory requirements.

Experience

7-10 Years

Level

Management

Education

BSE