Materials Engineer Resume

Summary : Results-driven Materials Engineer with over 10 years of experience in materials development, testing, and quality assurance. Proven track record in optimizing material properties and enhancing product performance through innovative engineering solutions.

Skills : Material Analysis Software, Tensile Testing, Differential Scanning, Hardness Testing

Description :

- Supervised quality assurance for materials in power plant projects, ensuring compliance with industry standards.

- Conducted thorough inspections of materials, ensuring adherence to documented procedures and specifications.

- Developed and reviewed quality documentation, enhancing subcontractor compliance.

- Coordinated destructive and nondestructive testing of materials, interpreting results to inform engineering decisions.

- Designed and implemented test programs, providing training to quality personnel on best practices.

- Led technical engineering activities, focusing on problem-solving and process improvements.

- Ensured compliance with ASME standards, focusing on carbon and stainless steel materials.

Experience

7-10 Years

Level

Management

Education

M.S. Materials Eng.

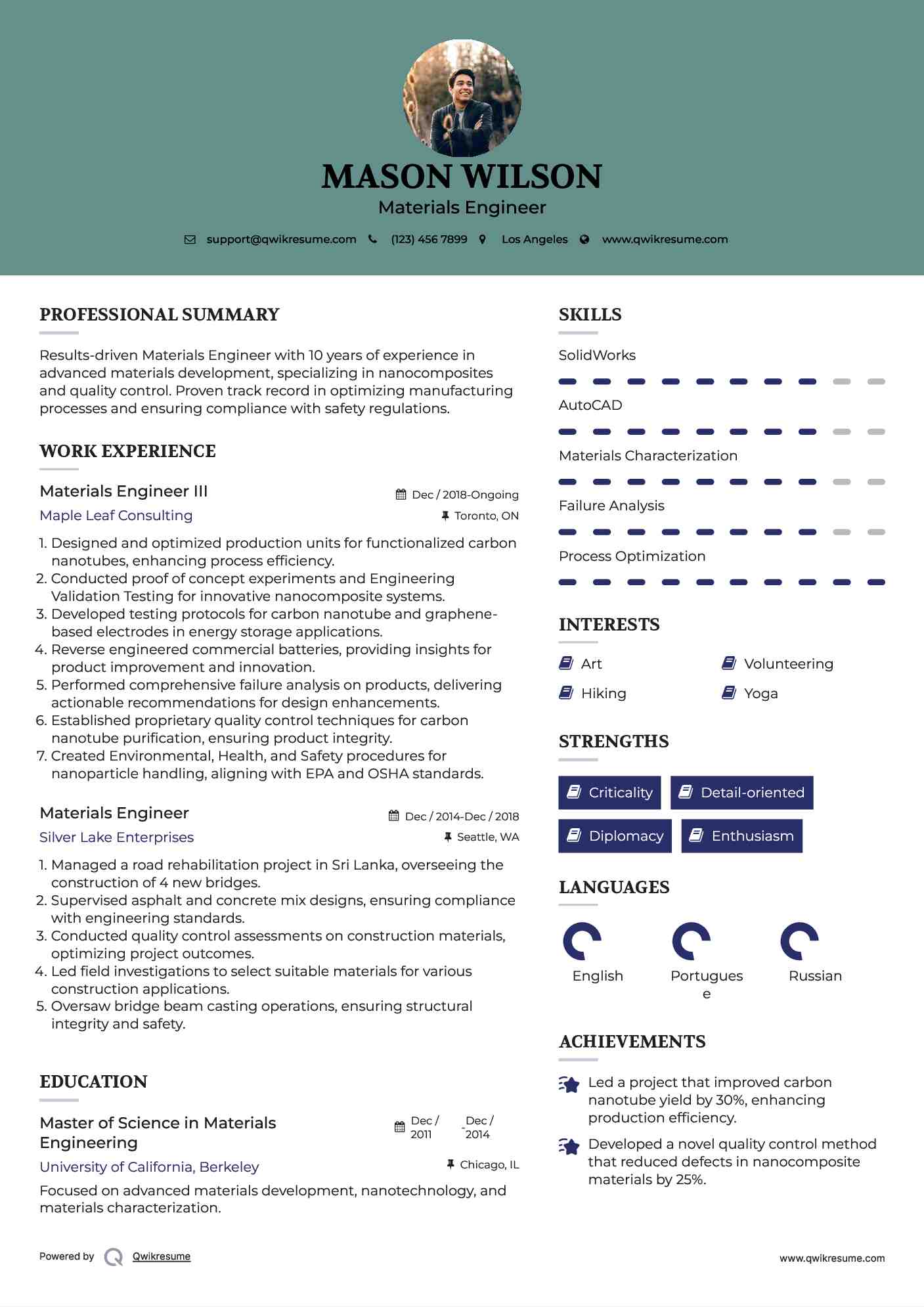

Materials Engineer III Resume

Summary : Results-driven Materials Engineer with 10 years of experience in advanced materials development, specializing in nanocomposites and quality control. Proven track record in optimizing manufacturing processes and ensuring compliance with safety regulations.

Skills : SolidWorks, AutoCAD, Materials Characterization, Failure Analysis, Process Optimization

Description :

- Designed and optimized production units for functionalized carbon nanotubes, enhancing process efficiency.

- Conducted proof of concept experiments and Engineering Validation Testing for innovative nanocomposite systems.

- Developed testing protocols for carbon nanotube and graphene-based electrodes in energy storage applications.

- Reverse engineered commercial batteries, providing insights for product improvement and innovation.

- Performed comprehensive failure analysis on products, delivering actionable recommendations for design enhancements.

- Established proprietary quality control techniques for carbon nanotube purification, ensuring product integrity.

- Created Environmental, Health, and Safety procedures for nanoparticle handling, aligning with EPA and OSHA standards.

Experience

10+ Years

Level

Management

Education

MSc Materials Eng.

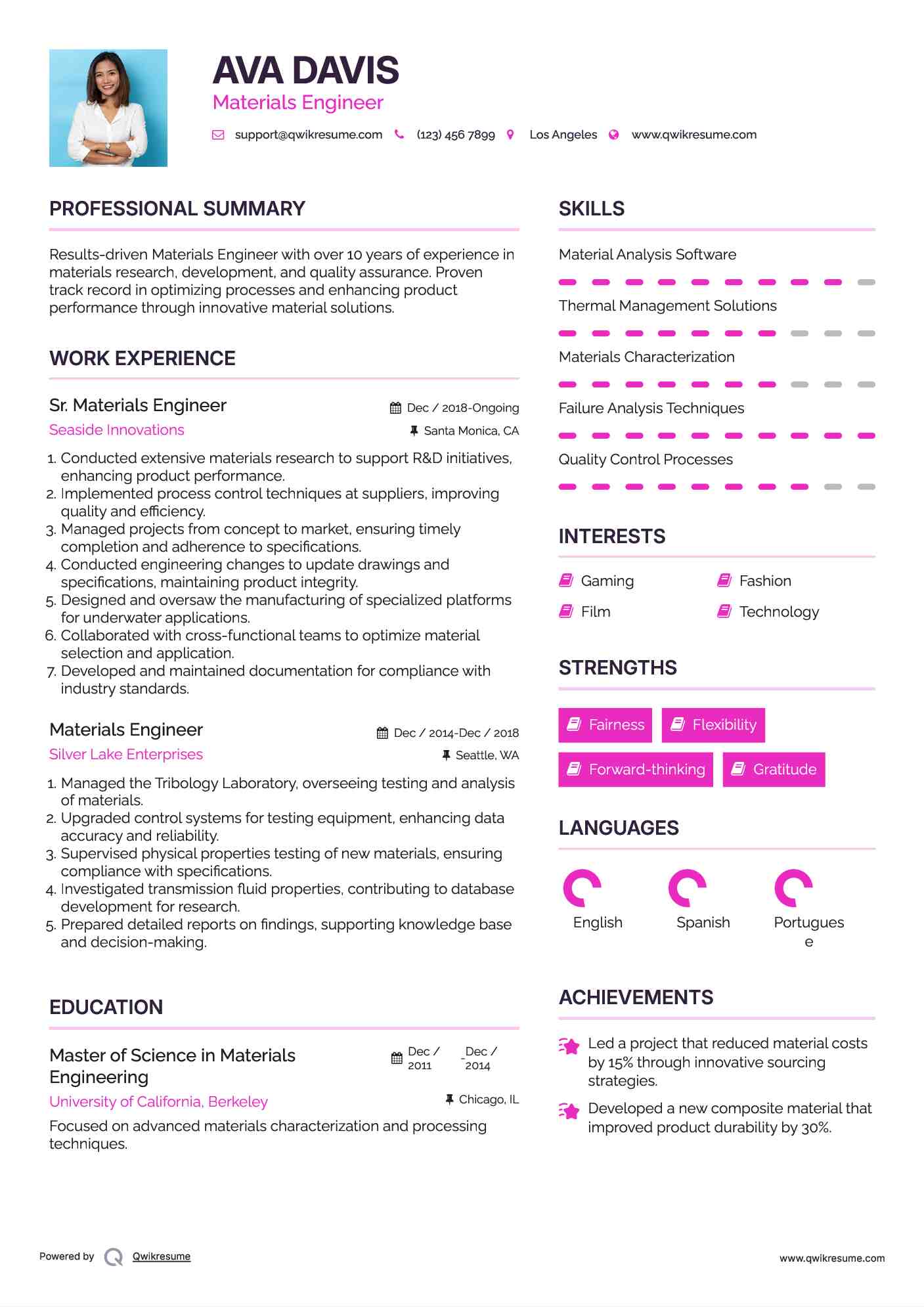

Sr. Materials Engineer Resume

Summary : Results-driven Materials Engineer with over 10 years of experience in materials research, development, and quality assurance. Proven track record in optimizing processes and enhancing product performance through innovative material solutions.

Skills : Material Analysis Software, Thermal Management Solutions, Materials Characterization, Failure Analysis Techniques, Quality Control Processes

Description :

- Conducted extensive materials research to support R&D initiatives, enhancing product performance.

- Implemented process control techniques at suppliers, improving quality and efficiency.

- Managed projects from concept to market, ensuring timely completion and adherence to specifications.

- Conducted engineering changes to update drawings and specifications, maintaining product integrity.

- Designed and oversaw the manufacturing of specialized platforms for underwater applications.

- Collaborated with cross-functional teams to optimize material selection and application.

- Developed and maintained documentation for compliance with industry standards.

Experience

10+ Years

Level

Senior

Education

MSc Materials Eng.

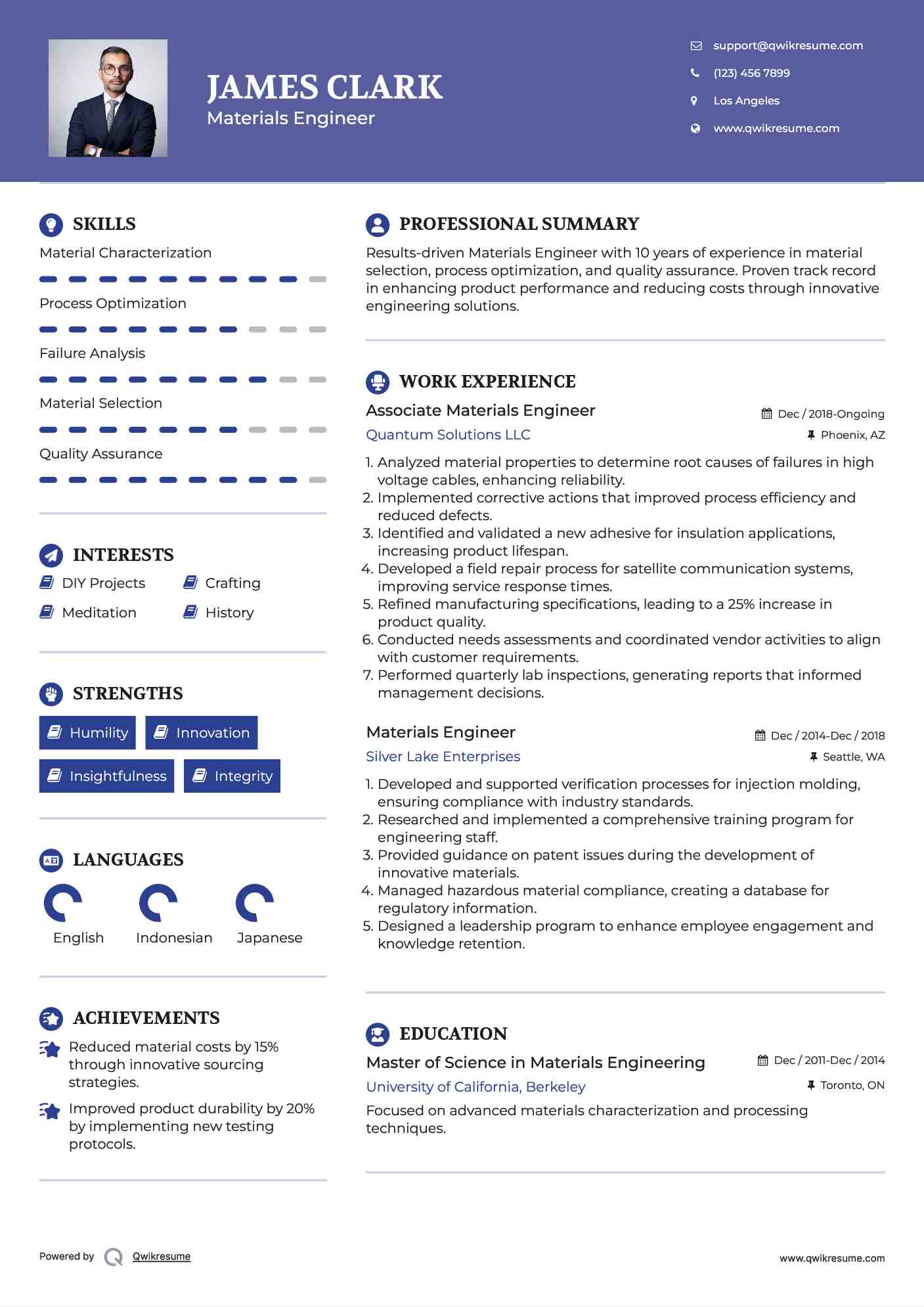

Associate Materials Engineer Resume

Summary : Results-driven Materials Engineer with 10 years of experience in material selection, process optimization, and quality assurance. Proven track record in enhancing product performance and reducing costs through innovative engineering solutions.

Skills : Material Characterization, Process Optimization, Failure Analysis, Material Selection, Quality Assurance

Description :

- Analyzed material properties to determine root causes of failures in high voltage cables, enhancing reliability.

- Implemented corrective actions that improved process efficiency and reduced defects.

- Identified and validated a new adhesive for insulation applications, increasing product lifespan.

- Developed a field repair process for satellite communication systems, improving service response times.

- Refined manufacturing specifications, leading to a 25% increase in product quality.

- Conducted needs assessments and coordinated vendor activities to align with customer requirements.

- Performed quarterly lab inspections, generating reports that informed management decisions.

Experience

10+ Years

Level

Senior

Education

M.S. Materials Eng.

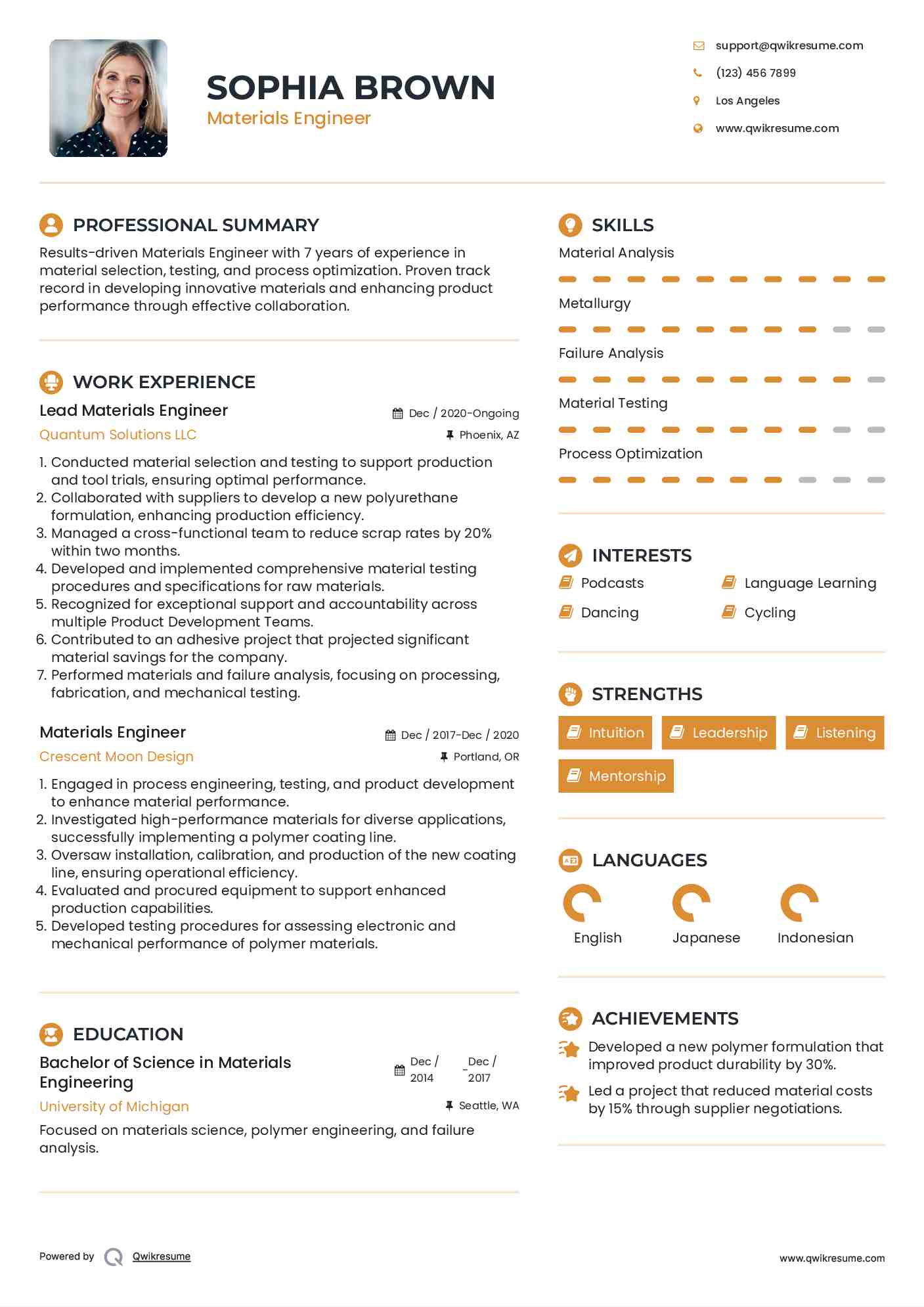

Lead Materials Engineer Resume

Headline : Results-driven Materials Engineer with 7 years of experience in material selection, testing, and process optimization. Proven track record in developing innovative materials and enhancing product performance through effective collaboration.

Skills : Material Analysis, Metallurgy, Failure Analysis, Material Testing, Process Optimization

Description :

- Conducted material selection and testing to support production and tool trials, ensuring optimal performance.

- Collaborated with suppliers to develop a new polyurethane formulation, enhancing production efficiency.

- Managed a cross-functional team to reduce scrap rates by 20% within two months.

- Developed and implemented comprehensive material testing procedures and specifications for raw materials.

- Recognized for exceptional support and accountability across multiple Product Development Teams.

- Contributed to an adhesive project that projected significant material savings for the company.

- Performed materials and failure analysis, focusing on processing, fabrication, and mechanical testing.

Experience

5-7 Years

Level

Executive

Education

B.S. Materials Eng.

Materials Engineer/Co-ordinator Resume

Summary : Results-driven Materials Engineer with 10 years of experience in materials development, testing, and quality assurance. Proven track record in optimizing processes and enhancing product performance through innovative material solutions.

Skills : Material characterization, Failure analysis, Thermal analysis, Mechanical testing

Description :

- Acted as the primary materials specialist, collaborating with R&D to develop innovative material solutions.

- Coordinated material processes and product development to enhance quality and reduce costs.

- Engaged with suppliers to improve product quality and streamline manufacturing processes.

- Provided comprehensive technical support for material processes and product development.

- Conducted field testing and analysis of materials, including soil, asphalt, and concrete.

- Collaborated with suppliers to refine materials and develop effective testing plans.

- Designed and executed qualification test plans, managing projects through various stages.

Experience

10+ Years

Level

Management

Education

M.S. Materials Eng.

Lead Materials Engineer Resume

Summary : Results-driven Materials Engineer with 10 years of experience in materials development, failure analysis, and process optimization. Proven track record in enhancing product performance and reliability through innovative engineering solutions.

Skills : Materials Analysis Software, Finite Element Analysis, Material Property Evaluation, Failure Analysis, Materials Characterization

Description :

- Supervised the upgrade of control systems for friction analyzers, enhancing testing accuracy and efficiency.

- Conducted physical properties testing on experimental materials, ensuring compliance with industry standards.

- Investigated transmission fluid properties, contributing to a comprehensive research database.

- Prepared detailed reports on findings, supporting core knowledge base and decision-making.

- Performed failure analysis to address global application development and production challenges.

- Provided technical materials engineering support to refineries, achieving significant cost savings and reliability improvements.

- Independently completed over 400 root cause failure analysis reports, driving continuous improvement initiatives.

Experience

7-10 Years

Level

Consultant

Education

MSc Materials Eng.

Materials Engineer/Representative Resume

Summary : Results-driven Materials Engineer with over 10 years of experience in materials selection, testing, and performance analysis. Proven track record in developing innovative solutions and optimizing material properties for diverse applications.

Skills : Material Analysis, Finite Element Analysis, Data Analysis, Material Selection, Failure Analysis

Description :

- Authored global material specifications and performance standards for automotive components, enhancing product quality.

- Facilitated material selection and failure analysis for Ford and Lincoln programs, ensuring compliance with industry standards.

- Created laboratory test methods for performance specifications, improving testing accuracy for weathering and adhesion.

- Conducted supplier audits to drive process improvements and reduce warranty claims.

- Evaluated emerging technologies to integrate innovative materials into future vehicle designs.

- Reviewed engineering drawings for material specifications, ensuring alignment with performance requirements.

- Developed global performance specifications for chrome plating processes, enhancing product aesthetics and durability.

Experience

10+ Years

Level

Senior

Education

MSc Materials Eng.

Materials Engineer/Technician Resume

Summary : Results-driven Materials Engineer with 10 years of experience in material testing, quality assurance, and product development. Proven expertise in optimizing material properties and ensuring compliance with industry standards.

Skills : Material Specification, Data Analysis, Material Testing, Quality Assurance, Process Optimization

Description :

- Reviewed and approved precast concrete mix designs, ensuring compliance with industry standards.

- Evaluated new concrete products from manufacturers to meet specifications and business needs.

- Supported Quality Assurance teams to deliver high-quality concrete products across multiple projects.

- Assisted field staff during concrete placement and trial batching to ensure optimal performance.

- Taught certification classes for concrete mix design, enhancing producer capabilities.

- Standardized Quality Assurance Plans and edited a comprehensive Materials Manual for local projects.

- Conducted sampling and testing of transportation materials to ensure compliance with safety standards.

Experience

7-10 Years

Level

Management

Education

M.S. Materials Eng.

Materials Engineer Resume

Summary : Results-driven Materials Engineer with 10 years of experience in materials development and analysis. Expertise in metallic and polymer materials, failure analysis, and process optimization to enhance product performance and reliability.

Skills : Materials characterization, Failure analysis, Process optimization, Material selection, Statistical process control

Description :

- Collaborated with production teams to analyze material properties and optimize processing conditions for enhanced performance.

- Developed and implemented a laboratory sample tracking system to streamline workflow and improve efficiency.

- Engaged with stakeholders to define project timelines and deliver regular updates on material analysis and testing.

- Generated comprehensive reports detailing findings and recommendations for product engineers, facilitating informed decision-making.

- Utilized Design of Experiments (DOE) to refine powder metal manufacturing processes, enhancing product quality.

- Conducted thorough analysis of raw materials and processing parameters to ensure compliance with industry standards.

- Achieved a 25% increase in first-pass yield for high-volume powder metal components through process improvements.

Experience

10+ Years

Level

Management

Education

M.S. Materials Eng.