Metallurgical Engineer Resume

Objective : Results-driven Metallurgical Engineer with 5 years of experience in materials analysis, quality control, and process optimization. Proven track record in enhancing metallurgical processes and product quality in manufacturing environments.

Skills : Metallurgical Testing, Process Optimization, Materials Characterization, Quality Assurance

Description :

- Conducted extensive metallurgical research on Copper and Aluminum rod and wire processing, leading to enhanced production techniques.

- Led a cross-functional team to improve the casting and performance of Copper alloys, resulting in a 15% increase in efficiency.

- Analyzed metallurgical properties of Copper and Aluminum alloys, providing critical data for product development.

- Utilized SEM-EDX and ICP for detailed analysis of wire breaks and alloy compositions, improving quality control.

- Investigated and optimized Nickel and Silver electroplating processes, enhancing product durability.

- Collaborated with multi-plant teams to identify and implement operational improvements, boosting overall productivity.

- Updated and maintained purchase specifications for Copper and Aluminum materials, ensuring compliance with industry standards.

Experience

2-5 Years

Level

Junior

Education

B.S. Metallurgical Eng.

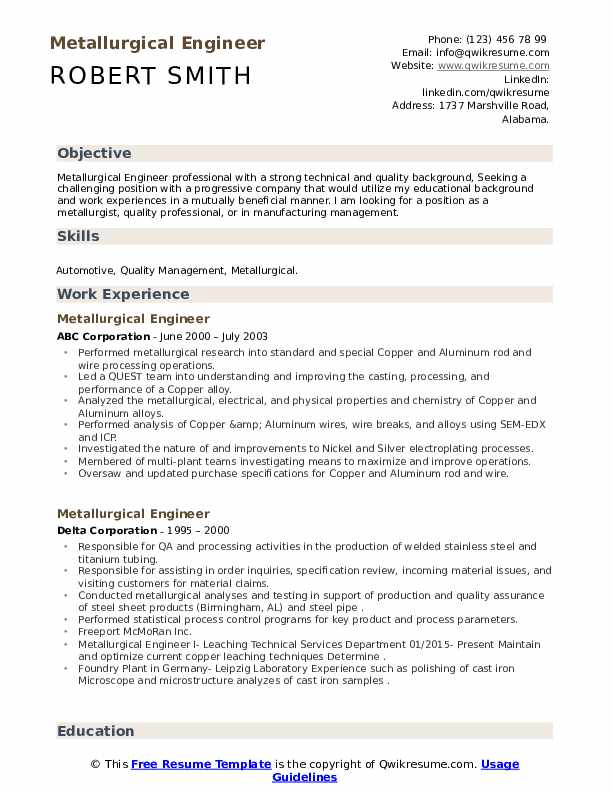

Metallurgical Engineer Resume

Objective : Detail-oriented Metallurgical Engineer with 5 years of experience in materials analysis, quality assurance, and process optimization. Proven ability to enhance product quality and efficiency through advanced metallurgical techniques.

Skills : Metallurgical Software, Data Analysis Techniques, X-Ray Diffraction Analysis, Optical Emission Spectroscopy, Database Management

Description :

- Conducted metallurgical examinations using advanced techniques and equipment, including Spectromax and the Leco oxygen machine, ensuring compliance with industry standards.

- Generated comprehensive reports detailing testing operations, facilitating informed decision-making for product approval.

- Executed titrations on various coolants to assess chemical properties and ensure optimal performance.

- Managed Heat Treatment production, overseeing operators and maintaining equipment such as endothermic generators and rotary furnaces.

- Developed an Excel-based heat treat recipe system, optimizing various products' furnace temperature, time, and quench rates.

- Completed training in engineering print interpretation, enhancing technical communication skills.

- Performed precision inspections on components, verifying specifications for parallelism, flatness, and surface finish against engineering prints.

Experience

2-5 Years

Level

Junior

Education

B.S. Metallurgical Eng.

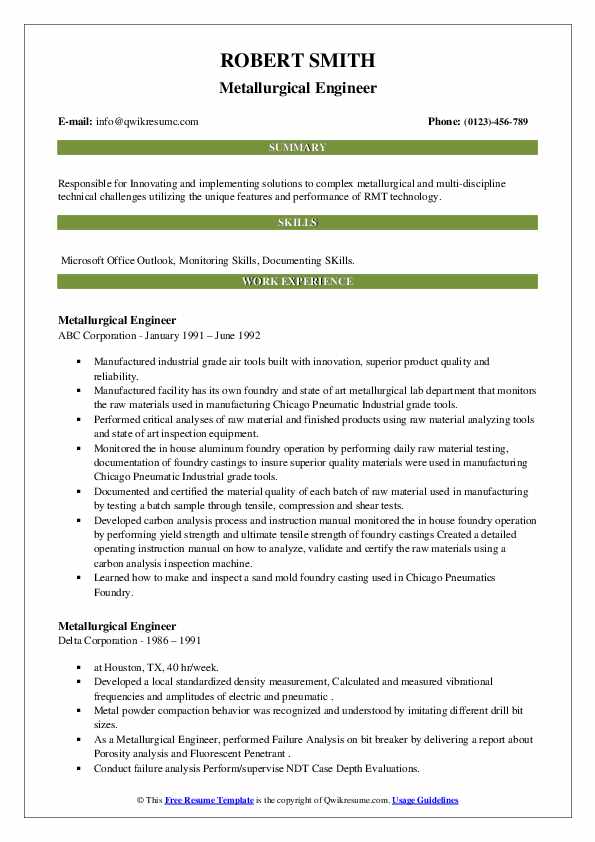

Metallurgical Engineer Resume

Objective : Results-driven Metallurgical Engineer skilled in advanced materials characterization and metallurgical testing. Successfully led projects that improved material properties, resulting in a 15% increase in product durability and customer satisfaction.

Skills : Material Analysis Software, Quality Control Techniques, Metallurgical Testing, Failure Analysis, Process Optimization

Description :

- Engineered and optimized industrial-grade air tools, ensuring superior product quality and reliability through innovative metallurgical practices.

- Oversaw the in-house foundry and metallurgical lab, ensuring compliance with quality standards for raw materials used in manufacturing.

- Conducted comprehensive analyses of raw materials and finished products using advanced metallurgical testing equipment.

- Monitored aluminum foundry operations, performing daily raw material testing and documentation to guarantee high-quality output.

- Certified material quality for each batch by conducting tensile, compression, and shear tests on samples.

- Developed and implemented a carbon analysis process, creating an instruction manual for validating and certifying raw materials.

- Acquired skills in sand mold casting and inspection, contributing to the production of high-quality foundry components.

Experience

2-5 Years

Level

Executive

Education

BSc Met Eng

Metallurgical Engineer Resume

Summary : Dedicated Metallurgical Engineer with expertise in heat treatment and alloy design. Achieved significant cost savings through process improvements and innovative solutions, contributing to a 20% reduction in production time and enhanced product quality.

Skills : Project Management, Metallurgical Analysis, Failure Analysis, Materials Selection, Quality Assurance

Description :

- Conducted comprehensive failure analysis and generated detailed lab reports to inform process improvements.

- Coordinated with regulatory bodies to maintain air quality standards for plasma spray operations, preventing potential shutdowns.

- Oversaw plasma system layout, procurement, and qualification, enhancing operational efficiency.

- Performed rigorous quality checks on diffusion and overlay coatings, as well as laser and TIG welding on superalloys.

- Utilized Ion Chromatography to analyze acid-stripping solutions, ensuring contamination control and concentration monitoring.

- Collaborated with cross-functional teams to implement process improvements, resulting in enhanced product quality.

- Collaborated with cross-functional teams to design and optimize heat treatment processes, resulting in enhanced mechanical properties of alloys.

Experience

10+ Years

Level

Senior

Education

BSc ME

Metallurgical Engineer Resume

Headline : Metallurgical Engineer with a strong background in corrosion resistance and surface treatment technologies. Developed and implemented strategies that reduced corrosion rates by 30%, extending the lifespan of critical components in industrial applications.

Skills : Metallurgy Expertise, Materials Characterization, Failure Analysis, Process Optimization, Heat Treatment Techniques

Description :

- Dedicated 6 months as a full-time Metallurgical Engineer and 1 year part-time while pursuing B.Eng.

- Gained hands-on experience in the chemical and physical characterization of metals and alloys.

- Developed expertise in optical emission spectrometry (OES) and wavelength dispersive X-ray fluorescence (WD-XRF) for compositional analysis.

- Maintained service records and calibrations for analytical equipment.

- Analyzed samples and generated detailed reports on material composition.

- Established calibration protocols for WD-XRF and OES systems.

- Conducted wastewater analysis using Inductively Coupled Plasma to ensure compliance with environmental regulations.

Experience

5-7 Years

Level

Executive

Education

B.Eng. Metall.

Metallurgical Engineer Resume

Headline : Metallurgical Engineer with 7 years of experience in material testing, analysis, and process optimization. Proven track record in enhancing material properties and leading R&D projects to improve product reliability and performance.

Skills : Metallurgical Analysis, Material Supply Chain, Material Characterization, Failure Analysis

Description :

- Utilized advanced testing methods including Ultrasonic, XRF, and SEM to assess material properties and ensure compliance with industry standards.

- Enhanced mechanical properties of PH 13-8 Mo stainless steel by eliminating hydrogen embrittlement, resulting in a 30% increase in tensile strength.

- Directed R&D initiatives for vehicle brake components, achieving a 20% increase in part lifespan through design and material composition modifications.

- Conducted Weibull Analysis to determine failure rates and improve reliability of critical components.

- Implemented cost-reduction strategies that improved production yields and minimized waste.

- Developed and recommended manufacturing procedures to achieve required reliability levels for automotive parts.

- Collaborated with cross-functional teams to optimize processes across various steel grades.

Experience

5-7 Years

Level

Executive

Education

BSc ME

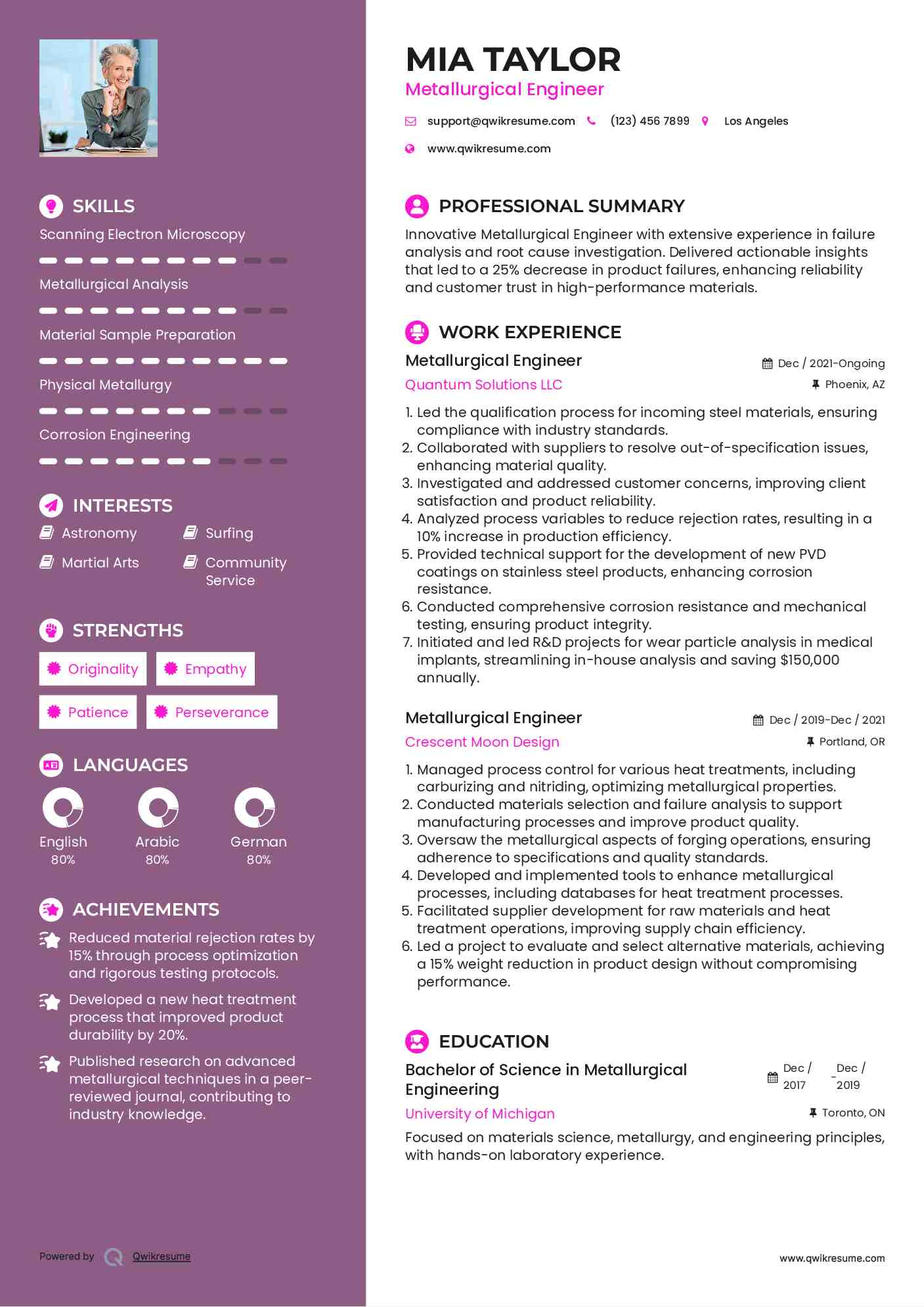

Metallurgical Engineer Resume

Objective : Innovative Metallurgical Engineer with extensive experience in failure analysis and root cause investigation. Delivered actionable insights that led to a 25% decrease in product failures, enhancing reliability and customer trust in high-performance materials.

Skills : Scanning Electron Microscopy, Metallurgical Analysis, Material Sample Preparation, Physical Metallurgy, Corrosion Engineering

Description :

- Led the qualification process for incoming steel materials, ensuring compliance with industry standards.

- Collaborated with suppliers to resolve out-of-specification issues, enhancing material quality.

- Investigated and addressed customer concerns, improving client satisfaction and product reliability.

- Analyzed process variables to reduce rejection rates, resulting in a 10% increase in production efficiency.

- Provided technical support for the development of new PVD coatings on stainless steel products, enhancing corrosion resistance.

- Conducted comprehensive corrosion resistance and mechanical testing, ensuring product integrity.

- Initiated and led R&D projects for wear particle analysis in medical implants, streamlining in-house analysis and saving $150,000 annually.

Experience

2-5 Years

Level

Junior

Education

B.S. Metallurgical Eng.

Metallurgical Engineer Resume

Summary : Metallurgical Engineer with over 10 years of experience in material processing, foundry operations, and quality assurance. Proven track record in optimizing metallurgical processes and leading teams to achieve production goals.

Skills : Material Characterization, Failure Analysis, Heat Treatment Processes, Casting Techniques, Corrosion resistance

Description :

- Oversaw all aspects of metallurgical processes, ensuring compliance with industry standards and safety regulations.

- Managed foundry operations, including metal melting, treatment, casting, and mold design, enhancing production efficiency.

- Designed and implemented sand casting tools, including patterns and core boxes, to improve product quality.

- Supervised a team of 25 employees, fostering a collaborative environment to meet production targets.

- Directed heat treatment operations for tools and dies in a vacuum furnace, optimizing material properties.

- Increased client engagement for failure analysis projects by 30% through effective communication and reporting.

- Enhanced service visibility through targeted marketing initiatives, including informative posters and blog content.

Experience

10+ Years

Level

Senior

Education

BSc Metallurgy

Metallurgical Engineer Resume

Objective : Proficient Metallurgical Engineer specializing in welding and joining technologies. Spearheaded initiatives that improved weld quality and reduced defects by 40%, significantly enhancing production efficiency and product integrity.

Skills : Advanced Excel Skills, Statistical Analysis Software, Minitab Proficiency, Matlab Programming, Metallurgical Testing

Description :

- Conducted comprehensive reports on material verifications, failure analysis, and benchmarking to enhance product quality.

- Collaborated with major automotive companies including Toyota and Ford on metallurgical projects, ensuring compliance with industry standards.

- Facilitated communication between multidisciplinary engineering teams to address analysis requests effectively.

- Managed international projects, coordinating with overseas partners to ensure timely completion and adherence to specifications.

- Developed expertise in ASTM testing procedures, contributing to improved testing accuracy and reliability.

- Implemented quality control measures using SPC charts, leading to significant product improvements and reduced waste.

- Executed experimental trials to validate new materials and processes, enhancing overall production efficiency.

Experience

2-5 Years

Level

Executive

Education

B.S. in Met. Eng.

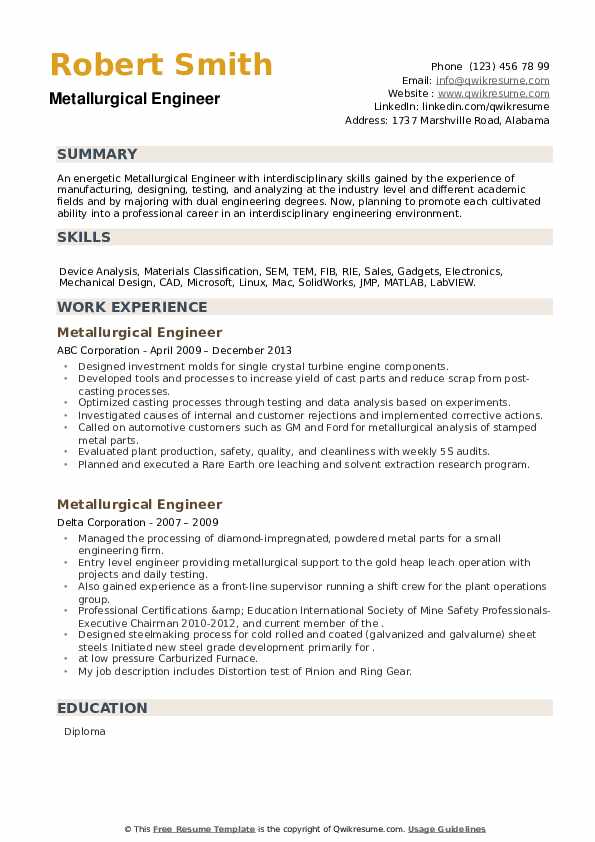

Metallurgical Engineer Resume

Objective : Metallurgical Engineer with 5+ years of experience in materials development and failure analysis. Proven track record in optimizing processes, reducing costs, and enhancing product performance in aerospace and automotive sectors.

Skills : Metallurgical Testing, Material Characterization, Transmission Electron Microscopy, Focused Ion Beam Analysis, Reactive Ion Etching

Description :

- Designed investment molds for single crystal turbine engine components, enhancing performance and reliability.

- Developed innovative tools and processes that increased yield of cast parts by 15% and minimized scrap.

- Optimized casting processes through rigorous testing and data analysis, leading to improved product quality.

- Investigated internal and customer rejection causes, implementing corrective actions that reduced rejections by 25%.

- Collaborated with automotive clients like GM and Ford for metallurgical analysis of stamped metal parts, ensuring compliance with specifications.

- Conducted weekly 5S audits to evaluate plant production, safety, and cleanliness, fostering a culture of continuous improvement.

- Planned and executed a Rare Earth ore leaching and solvent extraction research program, contributing to resource recovery initiatives.

Experience

2-5 Years

Level

Junior

Education

BSc ME