Piping Engineer Resume

Summary : Highly skilled Piping Engineer with 10 years of expertise in designing and optimizing piping systems for the oil and gas industry. Proficient in ASME B31.3 standards and advanced stress analysis methodologies. Eager to apply innovative engineering solutions and collaborative strategies to drive project success and enhance safety standards.

Skills : Stress Analysis, Piping Stress Analysis Techniques, Project Management, Commissioning Support

Description :

- Designed and analyzed piping systems for various industrial applications.

- Utilized AutoCAD and 3D modeling software to produce precise technical drawings in accordance with industry standards.

- Conducted stress analysis and ensured compliance with industry standards.

- Facilitated communication between clients and internal teams by addressing inquiries from various shops.

- Developed piping layouts and isometric drawings using CAD software.

- Created Excel macros to automate calculations for cut lengths, weights, and areas, significantly improving project execution efficiency.

- Collaborated with multidisciplinary teams to optimize project designs.

Experience

7-10 Years

Level

Management

Education

B.S. in ME

Sr. Piping Engineer Resume

Summary : Innovative Piping Engineer with a decade of experience in the design and optimization of complex piping systems across various sectors. Adept in applying ASME B31.3 standards and utilizing advanced stress analysis for improved project outcomes. Committed to enhancing operational efficiency and safety through strategic collaboration and technical excellence.

Skills : P&id Design And Development, Corrosion Engineering And Management, Construction Oversight And Management, Safety Regulations, Cost Estimation

Description :

- Managed project timelines and budgets for piping engineering tasks.

- Reviewed and approved vendor drawings and technical submittals.

- Conducted site inspections to ensure proper installation of piping systems.

- Prepared technical reports and documentation for project stakeholders.

- Implemented quality control measures during piping fabrication and installation.

- Assisted in the development of project safety plans and procedures.

- Utilized software tools for hydraulic and thermal analysis of piping systems.

Experience

7-10 Years

Level

Senior

Education

B.S. in ME

Jr. Piping Engineer Resume

Objective : Accomplished Piping Engineer with 5 years of hands-on experience in the design, analysis, and optimization of piping systems. Expertise in ASME B31.3 standards and advanced stress analysis methodologies. Passionate about delivering innovative solutions that enhance safety and project efficiency while fostering effective teamwork.

Skills : Quality Control, Industry Standards Compliance, Project Risk Management, Stakeholder Engagement, Software Proficiency

Description :

- Engineered and analyzed stress-critical piping systems, ensuring compliance with ASME B31.3 and other industry regulations.

- Developed efficient piping layouts that prioritized accessibility and cost-effectiveness for maintenance and inspections.

- Utilized advanced software to create detailed 3D models and isometric drawings, enhancing design accuracy.

- Reviewed and specified appropriate materials, including carbon steel and stainless steel, for various applications.

- Collaborated with multidisciplinary teams to optimize construction planning and execution strategies.

- Addressed and resolved quality assurance issues, implementing best practices to enhance project outcomes.

- Maintained thorough documentation to support QA processes and ensure regulatory compliance.

Experience

2-5 Years

Level

Junior

Education

B.S.M.E.

Piping Engineer III Resume

Summary : Dedicated Piping Engineer with a decade of comprehensive experience in the design and optimization of piping systems across various industries. Expert in ASME B31.3 compliance and advanced stress analysis techniques, consistently delivering innovative solutions that enhance project efficiency and safety. Ready to leverage technical skills and collaborative spirit to contribute to impactful engineering projects.

Skills : Piping Design Software (solidworks), 3d Modeling Software (pro/e), Fluid Dynamics, Project Management Software (sap), Presentation Software (powerpoint)

Description :

- Executed comprehensive designs for piping systems, ensuring compliance with ASME B31.3 standards.

- Collaborated on large-scale projects, providing construction support for a material storage facility.

- Engineered flex hoses to connect new equipment with existing utilities, enhancing system efficiency.

- Partnered with subject matter experts to develop utility gas piping for glovebox installations.

- Independently designed utility piping for a pre-fabricated change house facility, accommodating large groups.

- Created accurate isometric drawings and material take-offs (MTO) for effective project execution.

- Conducted stress analysis on piping systems, ensuring compliance with ASME standards and reducing failure rates.

Experience

10+ Years

Level

Senior

Education

B.S. ME

Piping Engineer II Resume

Summary : Dynamic Piping Engineer with a decade of experience in the design and optimization of piping systems for diverse industrial applications. Skilled in ASME B31.3 compliance and adept at conducting advanced stress analyses. Passionate about implementing innovative engineering practices to enhance operational efficiency and safety in all projects.

Skills : Autopipe Software, Piping Design, Smartplant 3d Review, Microstation Design Software, Analytical Skills

Description :

- Managed the design and engineering of piping systems, including detailed plans, elevations, and sections for various industrial applications.

- Executed the design and installation of a new urea storage tank with integrated fume scrubbers, enhancing environmental compliance.

- Developed a system to maintain optimal temperatures for urea, preventing crystallization and enhancing operational efficiency.

- Provided engineering support for a water-glycol cooling system, optimizing performance for steel production facilities.

- Analyzed data to identify and rectify abnormal conditions, ensuring system reliability.

- Calculated cooling water requirements to align with production goals, enhancing process efficiency.

- Assessed design modifications for the water-glycol cooling system, improving overall system performance.

Experience

10+ Years

Level

Senior

Education

BSc ME

Piping Engineer I Resume

Objective : Motivated Piping Engineer with 5 years of experience in the design and optimization of piping systems in the oil and gas sector. Proficient in utilizing ASME B31.3 standards and conducting detailed stress analysis to ensure system integrity. Driven to implement innovative engineering solutions that enhance project efficiency and safety while fostering collaborative teamwork.

Skills : Advanced Stress Analysis, 3d Modeling, Field Inspections, Technical Documentation

Description :

- Resolved stress issues during piping layout re-routes, ensuring compliance with equipment nozzle load requirements.

- Specified project specialty items from P&ID, enhancing system functionality and reliability.

- Prepared detailed data and cut sheets for specialty items, improving procurement efficiency.

- Developed comprehensive material requisitions for technical inquiries and purchases.

- Conducted thorough technical evaluations of vendor bids, ensuring compliance with project specifications.

- Completed all QA documentation and necessary reports for project compliance.

- Collaborated with cross-functional teams to ensure timely project execution and adherence to safety standards.

Experience

2-5 Years

Level

Executive

Education

B.S. ME

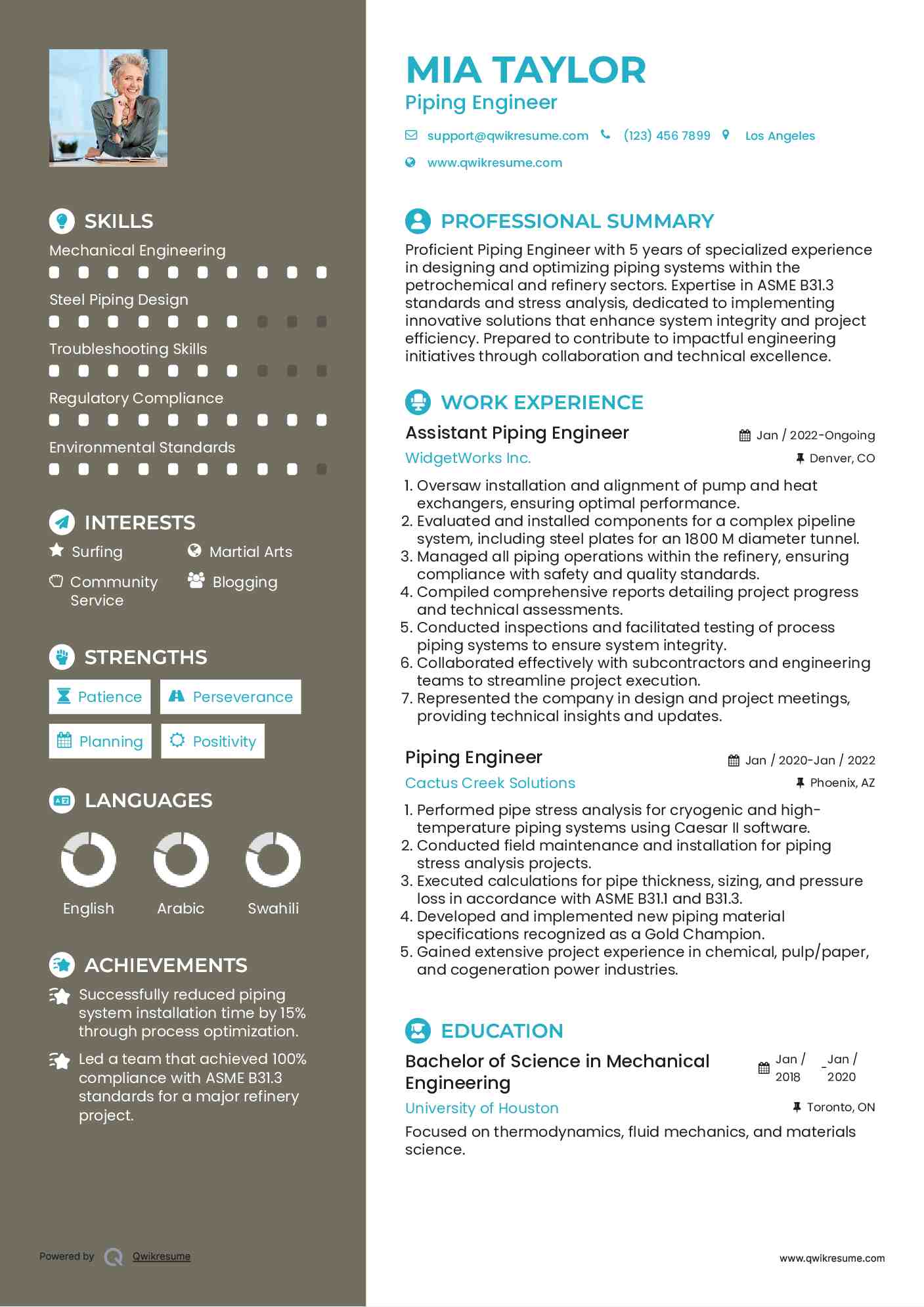

Assistant Piping Engineer Resume

Objective : Proficient Piping Engineer with 5 years of specialized experience in designing and optimizing piping systems within the petrochemical and refinery sectors. Expertise in ASME B31.3 standards and stress analysis, dedicated to implementing innovative solutions that enhance system integrity and project efficiency. Prepared to contribute to impactful engineering initiatives through collaboration and technical excellence.

Skills : Mechanical Engineering, Steel Piping Design, Troubleshooting Skills, Regulatory Compliance, Environmental Standards

Description :

- Oversaw installation and alignment of pump and heat exchangers, ensuring optimal performance.

- Evaluated and installed components for a complex pipeline system, including steel plates for an 1800 M diameter tunnel.

- Managed all piping operations within the refinery, ensuring compliance with safety and quality standards.

- Compiled comprehensive reports detailing project progress and technical assessments.

- Conducted inspections and facilitated testing of process piping systems to ensure system integrity.

- Collaborated effectively with subcontractors and engineering teams to streamline project execution.

- Represented the company in design and project meetings, providing technical insights and updates.

Experience

2-5 Years

Level

Executive

Education

B.S. in ME

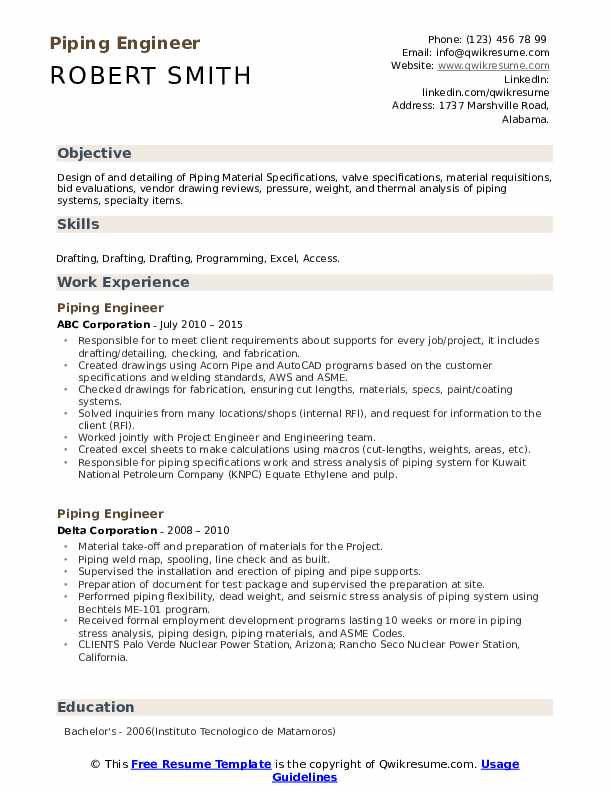

Associate Piping Engineer Resume

Summary : Seasoned Piping Engineer with a decade of experience in the design, analysis, and optimization of piping systems specifically for the oil and gas sector. Specialized in ASME B31.3 standards and proficient in advanced stress analysis techniques. Driven to deliver efficient, safe, and innovative piping solutions that propel project success and operational excellence.

Skills : Material Selection, Asme Standards, P&id Development, Construction Supervision, Pipe Support Design

Description :

- Prepared and verified Pipe Specifications, Valve Specifications, and Line List Data to ensure compliance with industry standards and project requirements.

- Conducted thorough reviews of various Pipe specifications including CS, SS, and exotic alloys to select appropriate materials.

- Developed and validated piping line lists in accordance with ASME B31.3, ASME B31.1, and ASME B16.5 standards.

- Analyzed process conditions and equipment data to establish line design parameters, test pressures, and stress levels.

- Oversaw the selection of Coatings, Insulation, and Stress Relieving requirements to enhance system integrity.

- Facilitated procurement processes for piping components by drafting precise purchase specifications based on engineering standards.

- Reviewed vendor documentation and proposals to ensure alignment with project specifications and quality standards.

Experience

10+ Years

Level

Senior

Education

B.S. in ME

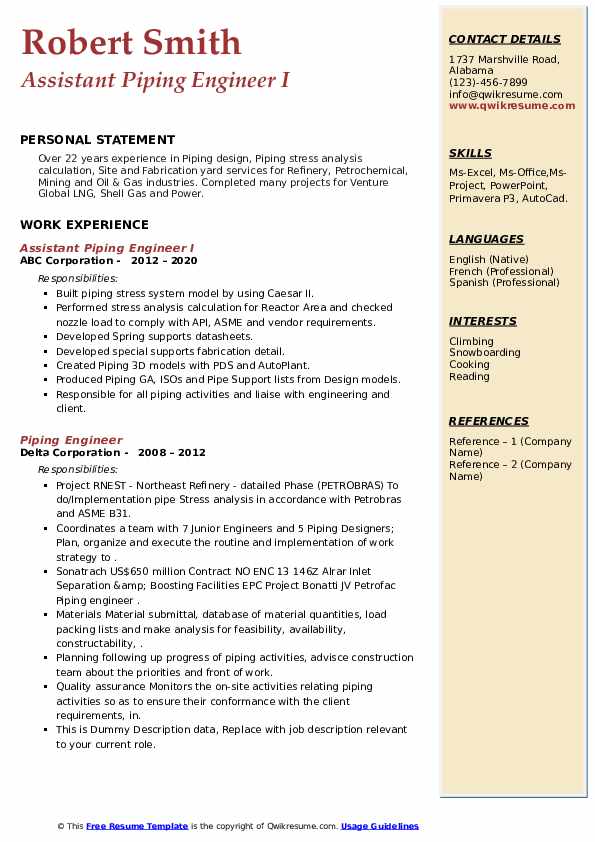

Assistant Piping Engineer I Resume

Summary : With a decade of experience in piping engineering, I excel in designing and optimizing intricate piping systems across the oil and gas sector. My expertise in ASME B31.3 compliance and advanced stress analysis ensures project integrity and efficiency. I am committed to implementing innovative solutions that enhance safety and drive successful project outcomes.

Skills : Corrosion Control, System Integration, Process Flow Diagrams, Presentation Skills, Project Scheduling

Description :

- Developed comprehensive piping stress models using Caesar II to ensure system integrity.

- Conducted detailed stress analysis for critical areas, ensuring compliance with API and ASME standards.

- Created and maintained spring support datasheets to optimize design integrity.

- Designed specialized support fabrication details to enhance project efficiency.

- Utilized PDS and AutoPlant to produce accurate 3D piping models.

- Generated Piping General Arrangement (GA) drawings, Isometric (ISO) layouts, and Pipe Support lists from design models.

- Managed all piping activities while liaising effectively with engineering teams and clients.

Experience

10+ Years

Level

Senior

Education

B.Sc. ME

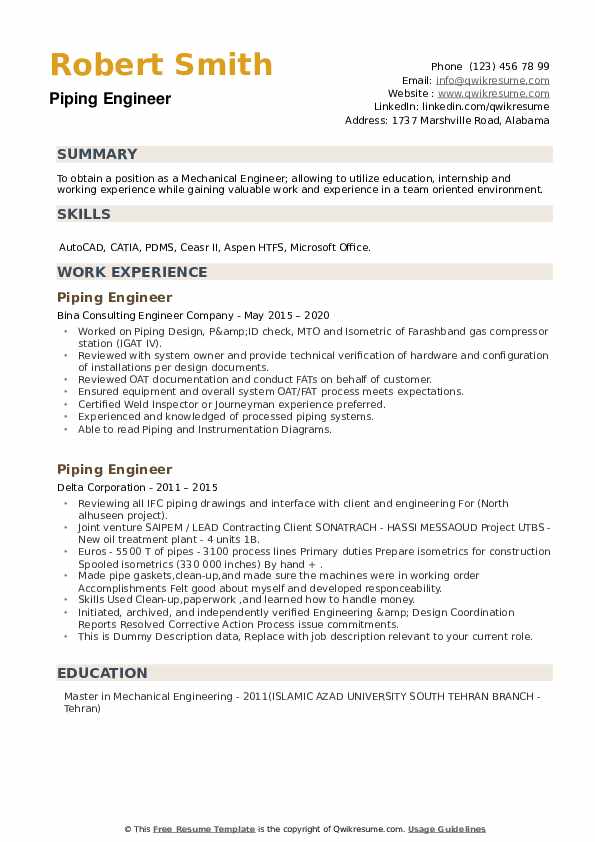

Piping Engineer Resume

Summary : Results-oriented Piping Engineer with 10 years of experience specializing in the design and optimization of piping systems across the oil and gas sector. Expertise in ASME B31.3 standards and advanced stress analysis techniques empowers me to deliver innovative solutions that enhance project efficiency and safety. Passionate about driving operational excellence through collaborative engineering practices.

Skills : Catia V5/v6 Design Software, Plant Design Management System, Caesar Ii Pipe Stress Analysis, Aspen Hysys Fluid Simulation, Time Management

Description :

- Designed and optimized piping systems for the Farashband gas compressor station IGAT IV, ensuring compliance with industry standards.

- Conducted technical verification of hardware installations, collaborating closely with system owners to ensure adherence to design documents.

- Reviewed operational acceptance testing (OAT) documentation and conducted factory acceptance tests (FATs) on behalf of clients.

- Ensured that equipment and overall system OAT and FAT processes met project expectations and specifications.

- Utilized advanced stress analysis techniques to assess and validate piping system designs.

- Interpreted and analyzed Piping and Instrumentation Diagrams (P&IDs) to enhance project accuracy.

- Trained junior engineers on industry standards and best practices in piping design and analysis.

Experience

7-10 Years

Level

Management

Education

B.S. in ME