Process Engineer Resume

Objective : Dynamic Process Engineer with 5 years of dedicated experience in optimizing process systems and enhancing operational efficiency. Proven ability to drive project execution, implement innovative solutions, and collaborate effectively with cross-functional teams. Committed to continuous improvement and delivering measurable results in complex engineering environments.

Skills : Safety Systems Design, Safety Analysis And Risk Assessment, Low-pressure Systems Engineering, Flare System Design And Analysis

Description :

- Executed process improvement projects at various Dow plants, enhancing operational efficiency.

- Played a key role in the commissioning and startup of the PDH-1 plant, ensuring timely delivery.

- Provided engineering support by developing Aspen models and conducting leak rate calculations for safety systems.

- Assisted in the pre- and post-commissioning walk-throughs of various systems, ensuring compliance with standards.

- Contributed to the propane methanol removal project, optimizing design specifications for key equipment.

- Collaborated with cross-functional teams to ensure successful completion of all engineering deliverables.

- Identified process feed variability, leading to a significant cost reduction by eliminating unnecessary equipment.

Experience

2-5 Years

Level

Senior

Education

B.S. Chem. Eng.

Process Engineer Specialist Resume

Headline : Accomplished Process Engineer with 7 years of expertise in refining processes and enhancing production efficiency. Skilled in implementing Lean methodologies and driving continuous improvement initiatives. Adept at collaborating with multidisciplinary teams to achieve operational excellence and deliver quantifiable results in complex manufacturing environments.

Skills : Process Optimization, Lean Six Sigma, Statistical Analysis, Process Improvement Methodologies, Continuous Improvement Techniques

Description :

- Oversaw finishing operations for windshields across three production lines, ensuring quality and efficiency.

- Led troubleshooting initiatives to identify and resolve production inefficiencies, enhancing throughput.

- Implemented poka-yoke techniques that successfully reduced distortion-related scrap from 300 to 30 pieces per day.

- Developed process improvement strategies that generated weekly cost savings of $85,000 on high-volume parts.

- Created and maintained standard work instructions, job safety analysis documents, PFMEAs, and control plans.

- Analyzed scrap data to uncover defect sources, facilitating targeted improvement efforts.

- Collaborated with upstream engineers to enhance quality checks, minimizing defect propagation.

Experience

5-7 Years

Level

Senior

Education

B.S. Chem. Eng.

Process Engineer Resume

Summary : With a decade of comprehensive experience in process engineering, I excel in optimizing production workflows and enhancing operational performance. My expertise encompasses project management, innovative process design, and cross-functional collaboration to drive efficiency and quality improvements. I am dedicated to delivering impactful solutions that contribute to organizational success.

Skills : Process Simulation Software, Project Coordination, Process Quality Management, Statistical Process Control, Risk Assessment, Process Validation

Description :

- Developed innovative applications in organic synthesis, focusing on distillation and microencapsulation for enhanced product quality.

- Designed and installed state-of-the-art reactors and pilot plants, optimizing performance for both liquid and solid materials.

- Led the optimization and automation of batch processes for various resin products, integrating emission control technologies.

- Commercialized novel technologies in polymerization and cross-linking, significantly improving product offerings.

- Managed the installation of robust industrial safety systems, ensuring compliance with PSM and MOC regulations.

- Oversaw the successful start-up of processing systems, achieving operational readiness ahead of schedule.

- Streamlined post-processing techniques for phenolic resins, enhancing production efficiency and product consistency.

Experience

7-10 Years

Level

Management

Education

B.S. Ch.E.

Process Engineer Assistant Resume

Objective : Enthusiastic Process Engineer Assistant with 2 years of experience in process optimization and quality assurance. Skilled in collaborating with diverse teams to enhance manufacturing efficiency and reduce costs. Committed to applying analytical skills and technical knowledge to drive successful project outcomes and support continuous improvement initiatives.

Skills : Process Improvement Management, Process Control Systems, Plc Programming And Testing, Process Flow Diagram Development, Piping And Instrumentation Diagrams, Capacity Planning And Analysis

Description :

- Defined technical specifications for product manufacturing equipment to meet safety and operational standards.

- Enhanced equipment layout and process flow to boost yield and minimize operational costs.

- Managed the completion of technical drawings and documentation for project proposals and equipment procurement.

- Conducted development studies to assess the impact of process inputs on product quality.

- Executed qualification activities for equipment installations, ensuring compliance with operational standards.

- Mentored interns and technicians in equipment operations and documentation practices.

- Facilitated technical reviews and project status meetings with cross-functional teams to align project goals.

Experience

0-2 Years

Level

Entry Level

Education

B.S. Chem. Eng.

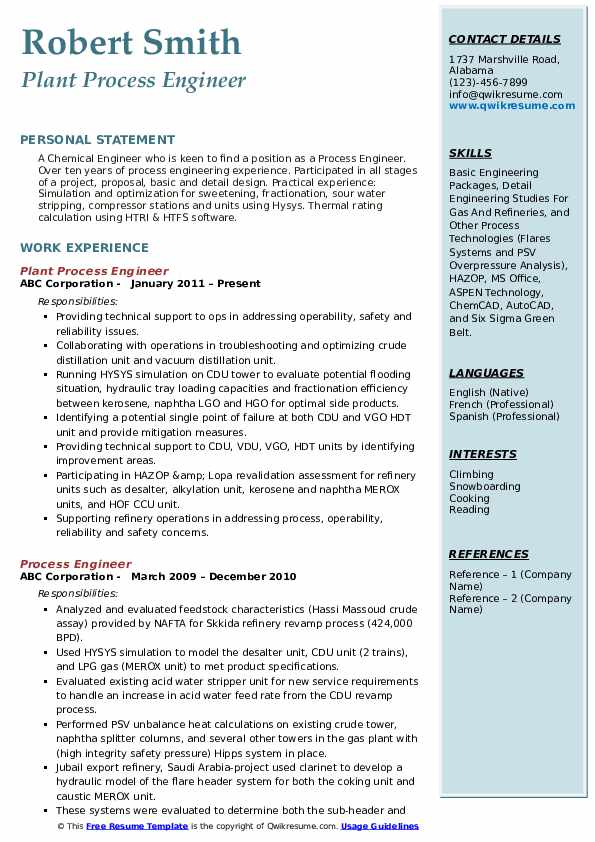

Process Engineer Resume

Objective : Passionate Process Engineer with 5 years of experience in enhancing process efficiency and optimizing production systems. Expertise in utilizing simulation tools like HYSYS for process modeling and troubleshooting. Proven success in implementing safety measures and collaborating with teams to drive continuous improvement initiatives that yield significant operational enhancements.

Skills : Process Design, Process Design And Optimization, Hazop And Risk Assessment, Data Analysis And Reporting, Aspen Plus Simulation, Chemical Process Simulation

Description :

- Provided technical support to operations, resolving safety and reliability issues efficiently.

- Collaborated with cross-functional teams to troubleshoot and optimize crude and vacuum distillation units.

- Executed HYSYS simulations to assess flooding risks and improve fractionation efficiency.

- Identified single points of failure in CDU and VGO HDT units, recommending effective mitigation strategies.

- Supported refinery units by pinpointing improvement opportunities and enhancing operational performance.

- Participated in HAZOP and LOPA assessments, ensuring compliance and safety across various units.

- Reviewed engineering deliverables from contractors, ensuring project completion and technical accuracy.

Experience

2-5 Years

Level

Senior

Education

BSCHE

Junior Process Engineer Resume

Objective : Resourceful Junior Process Engineer with 2 years of hands-on experience in optimizing chemical processes and enhancing operational workflows. Proficient in process simulation and control, I excel in collaborating with teams to implement effective solutions. Eager to contribute analytical skills and engineering knowledge to drive continuous improvement and operational success.

Skills : C Programming, Regulatory Compliance, Equipment Design, Production Planning

Description :

- Developed DCS graphics and highlighted equipment in P&ID for process visualization.

- Executed dynamic simulations of submodels, integrating them into the overall process model.

- Utilized Unisim Operations Toolkit for effective mapping between process models and control systems.

- Develop and optimize manufacturing processes to enhance efficiency and reduce costs.

- Managed change requests and plant operations based on operator feedback.

- Collaborated with the support team to troubleshoot software and hardware issues related to Unisim tools.

- Coordinated with marketing for inventory management and product planning.

Experience

0-2 Years

Level

Junior

Education

B.Sc. Ch.E.

Process Engineer Resume

Objective : Skilled Process Engineer with 2 years of experience in enhancing operational workflows and optimizing industrial processes. Expertise in utilizing simulation tools like HYSYS for process modeling and conducting process evaluations. Strong analytical abilities and a commitment to safety and efficiency, aiming to contribute to innovative engineering solutions that drive continuous improvement.

Skills : Data Analysis, Environmental Compliance, Material Science, Data Visualization, Simulation Software, Quality Assurance

Description :

- Monitored equipment performance to identify inefficiencies and maximize production output.

- Reviewed laboratory test results, analyzing deviations using HYSYS and AutoCAD for process design.

- Calculated equipment sizing and conducted heat and material balance assessments.

- Participated in updating management of change (MOC) procedures and auditing for implementation.

- Provided technical support to operations, ensuring optimization of plant facilities.

- Reviewed and approved feasibility studies and detailed engineering designs.

- Prepared technical safety studies and facilitated hazard identification workshops.

Experience

0-2 Years

Level

Entry Level

Education

B.S. in Chem Eng.

Senior Process Engineer Resume

Headline : Accomplished Senior Process Engineer with 7 years of experience in optimizing manufacturing processes and driving operational excellence. Expert in implementing advanced process design and Lean methodologies to enhance efficiency. Proven ability to collaborate with cross-functional teams and lead projects that deliver significant cost savings and performance improvements.

Skills : Ms Office Suite, Aspen Process Simulation, Chemcad Process Modeling, Six Sigma Methodologies, Quality Control, Aspen Hysys Process Modeling

Description :

- Developed innovative fabrication processes for next-generation photovoltaic products, enhancing efficiency and product quality.

- Served as the tool and process owner for advanced tube furnace operations, including pocl3 and bcl3 diffusion.

- Maintained strong relationships with equipment manufacturers to ensure optimal performance and reliability.

- Collaborated with manufacturers during process development, overseeing the procurement of critical characterization equipment.

- Streamlined the pocl3 process, leading to significant improvements in production efficiency.

- Established and executed preventive maintenance procedures, ensuring compliance with safety regulations.

- Contributed to the development of device monitoring systems, enhancing the characterization of silicon solar cells.

Experience

5-7 Years

Level

Senior

Education

B.S. Chem. Eng.

Process Engineer Resume

Objective : Accomplished Process Engineer with 5 years of experience in enhancing production processes and implementing effective solutions. Expertise in optimizing workflows, conducting root cause analysis, and collaborating with cross-functional teams to achieve operational targets. Dedicated to driving continuous improvement and delivering impactful results in fast-paced engineering environments.

Skills : Problem Solving, Project Execution, Process Control Engineering, Data Analysis Tools, Process Automation, Supply Chain Management

Description :

- Provided comprehensive technical support for polymerization operations, ensuring optimal production efficiency.

- Achieved key performance metrics in EHS and production through effective process monitoring.

- Conducted root cause analysis for equipment issues, implementing solutions that enhanced reliability.

- Monitored quality control data to fine-tune operating conditions, improving product consistency.

- Led maintenance coordination efforts to enhance process uptime and product quality.

- Identified and executed capital projects, driving significant process improvements.

- Facilitated operator training sessions to enhance proactive responses to process challenges.

Experience

2-5 Years

Level

Junior

Education

B.S. Ch.E.

Process Engineer Resume

Headline : Dedicated Process Engineer with over 7 years of experience in enhancing manufacturing processes and driving efficiency improvements. Expertise in applying Lean principles and process optimization techniques to achieve operational excellence. Proven ability to lead cross-functional teams and deliver innovative solutions that yield significant cost savings and performance enhancements.

Skills : Data Analysis Software, Technical Documentation, Performance Metrics, Process Optimization Techniques, Process Safety Management

Description :

- Designed and optimized manufacturing processes, improving efficiency and reducing costs.

- Collaborated with engineering teams to interpret and implement engineering drawings for complex components.

- Utilized SolidWorks for 3D modeling and process simulations, enhancing product design accuracy.

- Developed detailed process documentation and flow diagrams for improved communication and training.

- Managed project timelines and resources to ensure on-time delivery of manufacturing projects.

- Implemented quality control measures, leading to a significant decrease in defects.

- Facilitated communication between vendors, engineers, and quality teams to meet project specifications.

Experience

5-7 Years

Level

Senior

Education

B.S. Ch.E.

Jr. Principal Process Engineer Resume

Headline : Results-oriented Process Engineer with 7 years of experience in enhancing process efficiency and driving innovation in engineering projects. Demonstrated expertise in applying process optimization techniques and collaborating with teams to execute complex projects. Passionate about continuous improvement and delivering impactful solutions that drive operational excellence.

Skills : Root Cause Analysis, Lean Manufacturing, Unisim Design Suite, Promax Process Simulation, Aspen Energy Data Retrieval

Description :

- Specified equipment, evaluated bids, and selected vendors for key process components.

- Scaled up processes from laboratory data, optimizing pilot plant performance and final process design.

- Conducted start-up and troubleshooting for hazardous materials, ensuring compliance with safety regulations.

- Developed process flow diagrams (PFDs), P&IDs, and performed equipment sizing and material selection.

- Collaborated with cross-functional teams to ensure alignment in project goals and deliverables.

- Utilized simulation software to model and optimize process conditions, enhancing productivity.

- Led continuous improvement initiatives that resulted in measurable operational efficiencies.

Experience

5-7 Years

Level

Senior

Education

B.S. Chem. Eng.

Principal Process Engineer II Resume

Objective : Innovative Process Engineer with 2 years of experience in refining chemical processes and enhancing operational workflows. Skilled in applying process optimization techniques and collaborating with diverse teams to deliver effective solutions. Passionate about leveraging analytical skills to drive continuous improvement and optimize project outcomes in engineering environments.

Skills : Project Management, Process Mapping, Troubleshooting, Process Improvement, Flowcharting, Process Simulation

Description :

- Contributed to the Kitimat LNG Project, focusing on process engineering for LNG trains and associated utilities.

- Guided junior engineers by providing mentorship and technical support.

- Served as lead process engineer on the Chayvo Sakhalin Island project, managing deliverables through construction and detail phases.

- Supported startup and commissioning efforts, ensuring operational readiness of the plant.

- Developed and maintained comprehensive design history files to support project documentation.

- Executed failure analysis and risk management strategies, enhancing operational safety.

- Conducted verification and validation testing to ensure project compliance with engineering standards.

Experience

0-2 Years

Level

Junior

Education

B.S. Chem. Eng.

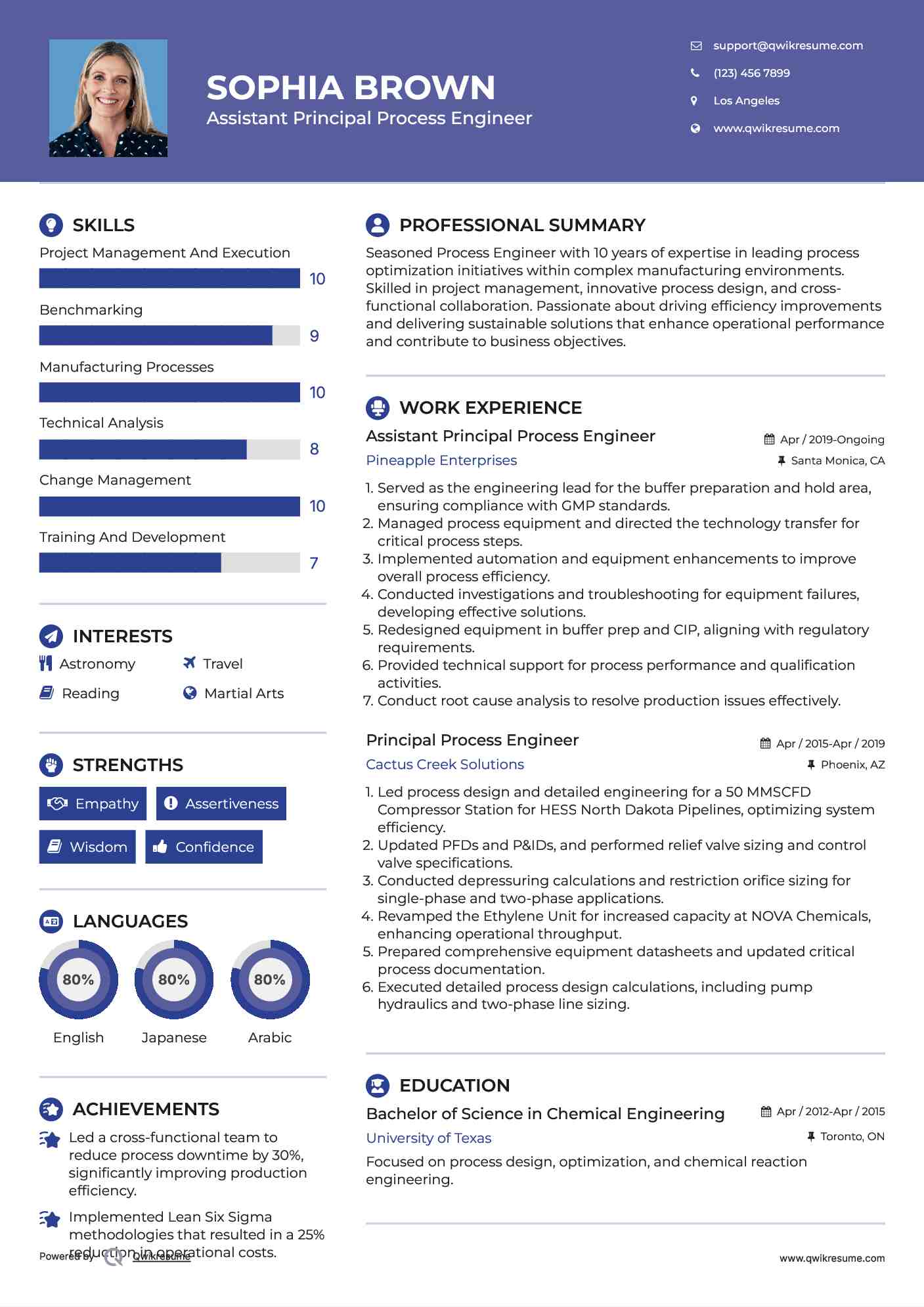

Assistant Principal Process Engineer Resume

Summary : Seasoned Process Engineer with 10 years of expertise in leading process optimization initiatives within complex manufacturing environments. Skilled in project management, innovative process design, and cross-functional collaboration. Passionate about driving efficiency improvements and delivering sustainable solutions that enhance operational performance and contribute to business objectives.

Skills : Project Management And Execution, Benchmarking, Manufacturing Processes, Technical Analysis, Change Management, Training And Development

Description :

- Served as the engineering lead for the buffer preparation and hold area, ensuring compliance with GMP standards.

- Managed process equipment and directed the technology transfer for critical process steps.

- Implemented automation and equipment enhancements to improve overall process efficiency.

- Conducted investigations and troubleshooting for equipment failures, developing effective solutions.

- Redesigned equipment in buffer prep and CIP, aligning with regulatory requirements.

- Provided technical support for process performance and qualification activities.

- Conduct root cause analysis to resolve production issues effectively.

Experience

10+ Years

Level

Executive

Education

B.S. Ch.E.

Principal Process Engineer Resume

Headline : Accomplished Principal Process Engineer with 7 years of experience in optimizing process systems within the petrochemical sector. Expertise in leading innovative solutions and enhancing operational efficiency through advanced simulation techniques. Committed to driving project success and fostering collaboration across multidisciplinary teams to achieve significant results.

Skills : Chemical Engineering, Safety Management, Cost Estimation Techniques, Cost Reduction, Energy Efficiency, Collaboration Skills

Description :

- Developed advanced simulation models for optimizing complex fractionation systems, enhancing efficiency.

- Led a $75 million project focused on solid-phase catalysis of C3H6 oligomer, achieving project milestones ahead of schedule.

- Managed a $20 million multi-site pressure relief system revalidation project with successful compliance outcomes.

- Specified and implemented a 40 MMBtu/hr hot oil Therminol heater, ensuring adherence to API standards.

- Designed a new plant laboratory in compliance with 29 CFR and NFPA regulations, enhancing operational safety.

- Engineered refrigeration requirements for low-pressure LPG storage tanks, optimizing safety and efficiency.

- Created a vapor-balance system for LPG barge unloading, realizing annual savings of $3 million.

Experience

5-7 Years

Level

Management

Education

B.S. Chem. Eng.