Process Integration Engineer Resume

Objective : As a Process Integration Engineer, designs and implements new equipment to enhance the development lifecycle and launch of mass production (MP) cell manufacturing lines. This includes opportunity to make meaningful contributions to products.

Skills : Process Engineering, Semiconductor Manufacturing Knowledge.

Description :

- Worked with production staff and engineers to develop, validate, and improve processes used in manufacturing and manufacturability of designs.

- Debugged process integration issues to ensure interactions between processes were kept under control.

- Built process documentation to accurately define the process to cross-functional teams (equipment, quality, production).

- Led and directed key strategic projects to achieve performance plans.

- Engaged team members through training, coaching, and empowerment in support of world-class manufacturing methodologies.

- Supported the Manufacturing Unit Leader in developing leadership capabilities and operations-maintenance integration for the manufacturing unit team.

- Led continuous improvement methods required to sustain performance plan results through projects and tasks.

Experience

0-2 Years

Level

Entry Level

Education

Bachelor's degree in Electrical Engineering

Senior Process Integration Engineer Resume

Summary : Support sites in achieving goals that are of importance to the potash business by providing technical resources, assessing execution plans of major innovative projects, contributing to design reviews, critical communications, and change management coaching.

Skills : Process Integration, Data Analysis.

Description :

- Led APT activities in both laboratory and full-scale operations.

- Drove best practices in scientific experimentation to produce trusted results.

- Actively engaged with operations, engineering, and functional groups to share learnings and build collaborative networks.

- Managed risk and removed barriers to ensure completion of project milestones, on time and on budget, for direct reports and project teams.

- Taught and mentored the research team on project execution where complex multi-department coordination was needed for successful implementation.

- Ensured regulatory, safety and environmental standards were adhered to, supporting Site safety programs and risk assessments.

- Continuously searched for novel technologies that could provide step change improvement to aspects of mining, mineral processing, and product development.

Experience

10+ Years

Level

Senior

Education

Bachelor's degree in Chemical Engineering

Process Integration Engineer Resume

Summary : As a Process Integration Engineer, provides the opportunity to deliver solutions to material and integration challenges faced with hybrid microelectronic packaging and advanced electronic and optoelectronic assemblies.

Skills : Problem-Solving, Collaboration.

Description :

- Promoted innovation with internal and external audiences, representing and APT with a high degree of integrity.

- Owned process tools, including responsibility for documentation, training and tool performance monitoring.

- Reported progress to management at weekly and monthly intervals.

- Specified new tools, chemicals and techniques as required to meet the business objectives.

- Provided leadership in the choice of materials and development of manufacturing processes.

- Liaised with and guided unit development packages with process engineering.

- Provided support for new products in manufacturing.

Experience

7-10 Years

Level

Management

Education

Bachelor's degree in Materials Science

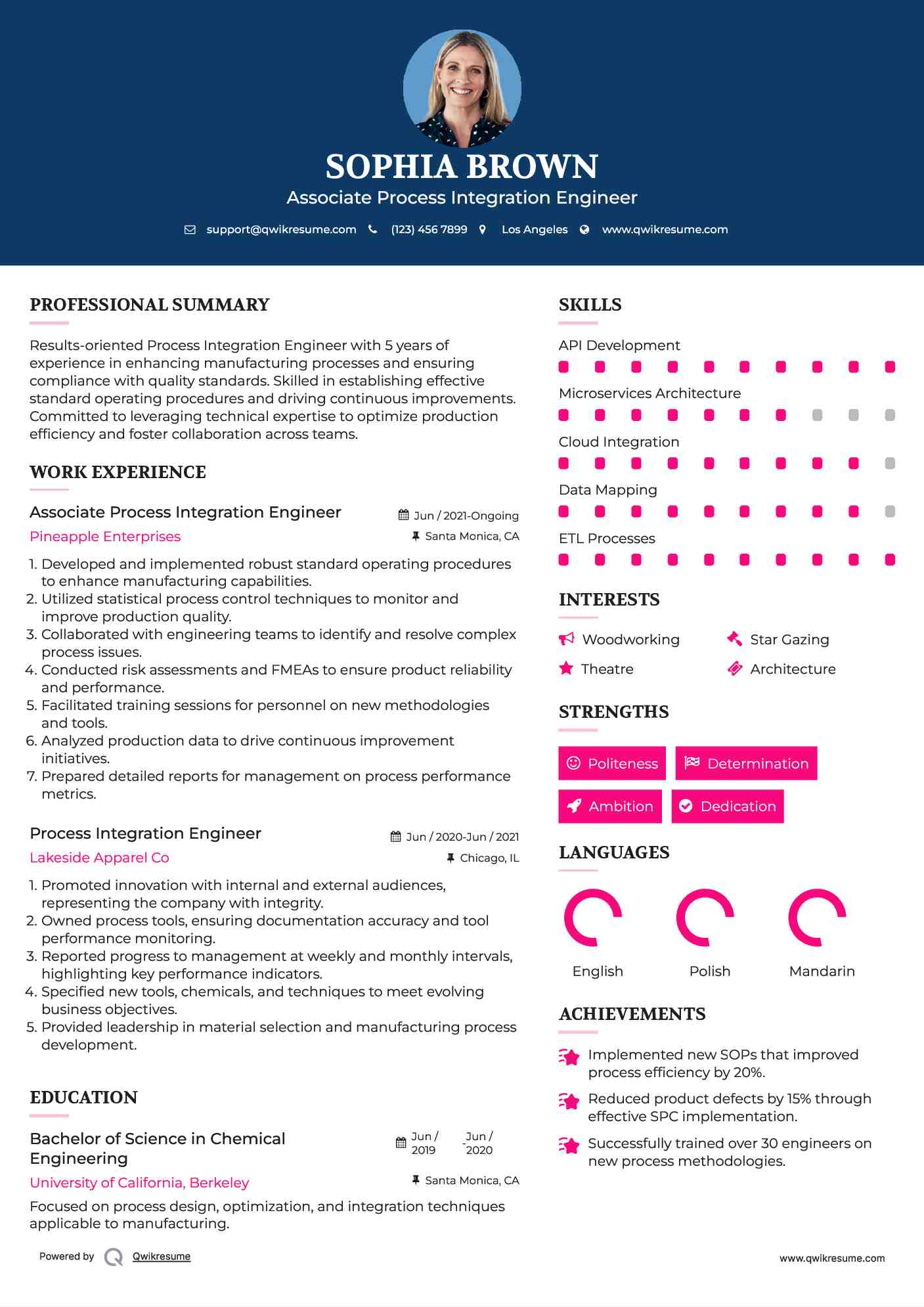

Associate Process Integration Engineer Resume

Objective : As a Process Integration Engineer, responsible for ensuring that manufacturing processes are capable of meeting both customer requirements and internal yield/recovery, quality, reliability, and productivity objectives by establishing and maintaining standard operating procedures, control plans, SPC, FMEAs and job instructions.

Skills : Collaboration, Project Management.

Description :

- Generated and maintained associated manufacturing documents.

- Worked with Quality group, defined and executed qualification plans to release new products/capabilities.

- Worked with external suppliers/contractors to evaluate new process capabilities.

- Communicated project status and technical updates to management.

- Developed processes and tools that designed-in robustness to the Body systems.

- Supported issue investigations with software teams and suppliers ensuring the use of structured problem-solving techniques.

- Captured best practice and lessons learned in process and tool chain improvements.

Experience

2-5 Years

Level

Executive

Education

Bachelor's degree in Electrical Engineering

Junior Process Integration Engineer Resume

Objective : As a Process Integration Engineer, served as a subject matter expert on manufacturing technologies, interfacing with design, manufacturing departments as well as with customers for multi-channel optical communications products.

Skills : Quality Assurance, Documentation, Continuous Improvement.

Description :

- Contributed to test data acquisition, management and automated reporting.

- Designed, collected data, analyzed and compiled reports on significantly complex process engineering experiments for a range of products, within safety guidelines.

- Designed and implemented new technology, products and analytical instrumentation.

- Developed, planned and executed process engineering projects for a range of products.

- Interacted with key customers to resolve significantly complex process engineering issues for a range of products to address our customers High-Value Problems (HVP).

- Defined and validated film measurement techniques. Trained engineers on the techniques and guided them in the interpretation of the data.

- Responsible for managing technical interfaces and challenges throughout the project lifecycle.

Experience

0-2 Years

Level

Junior

Education

Bachelor's degree in Chemical Engineering

Assistant Process Integration Engineer Resume

Summary : As a Process Integration Engineer, performs material compatibility and characterization testing to assist in the mechanical design, ensuring the optimal selection of materials for specific applications.

Skills : Analytical, API.

Description :

- Generated internal and external documentation for products, presentations, technical reports for integrated products and generated process engineering specifications for integrated products.

- Worked with multiple Module process engineers to achieve these goals.

- Utilized technical educational knowledge of semiconductor device physics to enable competitive technology through process improvements.

- Trained engineers, defined and implemented new methodologies, defined and applied new technologies, and/or troubleshooted and resolved significantly complex process engineering issues/problems.

- Performed material and device research to enhance thin film solar cell performance and stability and to reduce manufacturing cost.

- Responsible for projects or functions that were enablers to department goals and deliverables.

- Resolved action items on a timely basis to meet product development goals.

Experience

7-10 Years

Level

Consultant

Education

Bachelor's degree in Materials Science

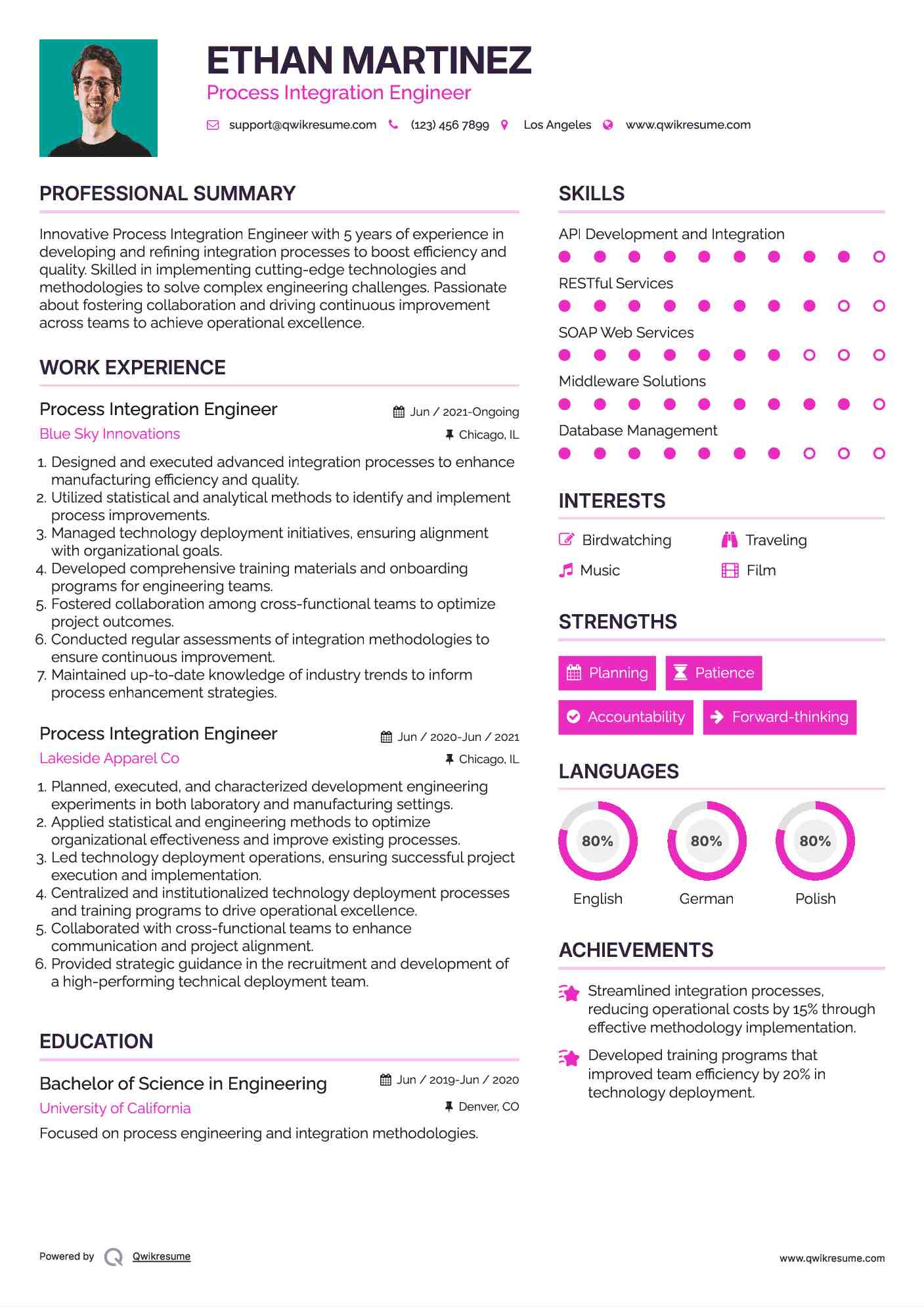

Process Integration Engineer Resume

Objective : As a Process Integration Engineer, responsible for supporting root cause failure analysis around process and quality losses, development of troubleshooting standards to improve MTBF, and decision support tools that drive continuous improvement.

Skills : Networking, Process integration experience.

Description :

- Planned, executed and characterized development engineering experiments in the laboratory and manufacturing environment.

- Applied statistical and engineering methods to optimize organizational effectiveness. Improved methods for use by others.

- Led and oversaw technology deployment operations processes, ensuring successful implementation and execution of projects.

- Developed, centralized, and institutionalized technology deployment processes, tools, training/onboarding programs, and metrics to drive operational excellence.

- Collaborated closely with cross-functional teams and work partners to foster collaboration, alignment, and effective communication.

- Provided leadership and guidance in recruiting and hiring practices to build a high-performing technical deployment team.

- Stayed up-to-date with industry trends and best practices in technology deployment and operations, bringing innovative ideas and solutions to the organization.

Experience

0-2 Years

Level

Fresher

Education

Bachelor's degree in Materials Science

Process Integration Engineer Resume

Objective : As a Process Integration Engineer, responsible for training engineers, defining and implementing new methodologies, defining and appling new technologies, and/or troubleshooting and resolving significantly complex process engineering issues/problems for a range of products.

Skills : Understanding APIs, web services.

Description :

- Monitored and evaluated performance metrics, identifying areas for improvement and implementing corrective actions as necessary.

- Fostered a culture of collaboration, accountability, and continuous improvement within the engineering operations team.

- Developed and troubleshooted wafer fabrication process modules in a clean-room wafer fab.

- Led projects by working closely with device and process engineers to explore, develop, troubleshoot, characterize, and validate unit processes and process steps.

- Drove requirements of process modules and flows to establish process steps and sequences with objective goals.

- Drove requirements for metrology and statistical process control.

- Drove responses to process issues and resolved excursions by working closely with process, epi, test, failure analysis, and other cross-functional engineering teams.

Experience

2-5 Years

Level

Executive

Education

Bachelor's degree in Electrical Engineering

Process Integration Engineer Resume

Summary : As a Process Integration Engineer, drove innovative techniques to characterize hardware, define methods and new technologies and apply them to characterize hardware, and/or perform hardware characterization on significantly complex systems for a range of programs, within safety guidelines.

Skills : Programming, Technical skills.

Description :

- Analyzed current processes and identified areas for improvement.

- Designed and built new processes to efficiency, reduce costs, and improve quality.

- Implemented, integrated, and maintained new processes, ensuring that they were properly integrated into the existing production system.

- Assembled reports that documented any changes made to processes.

- Identified and resolved process-related issues, such as those that arose during the production process.

- Monitored process performance and collected data to analyze improvements.

- Collaborated with other departments and teams, such as IT and operations.

Experience

7-10 Years

Level

Consultant

Education

Bachelor's degree in Electrical Engineering

Process Integration Engineer Resume

Summary : As a Process Integration Engineer, responsible for managing and controlling the electromagnetic spectrum. Made the invisible electromagnetic spectrum visible and controllable with industry-leading capabilities.

Skills : Knowledge of latest integration solutions.

Description :

- Worked with Process Engineers to develop processes to maximize operational efficiency.

- Optimized current processes to improve manufacturability, yield, and performance of products.

- Worked with process integration team to implement and integrate new/improved process workflow.

- Maintained documentation for new and improved processes for reference purposes.

- Interacted and coordinated with the product engineering team to resolve yield and quality issues.

- Provided training and guidance to Junior Engineers as needed.

- Managed a process integration team of Engineers and Technicians.

Experience

7-10 Years

Level

Management

Education

Bachelor's degree in Information Technology