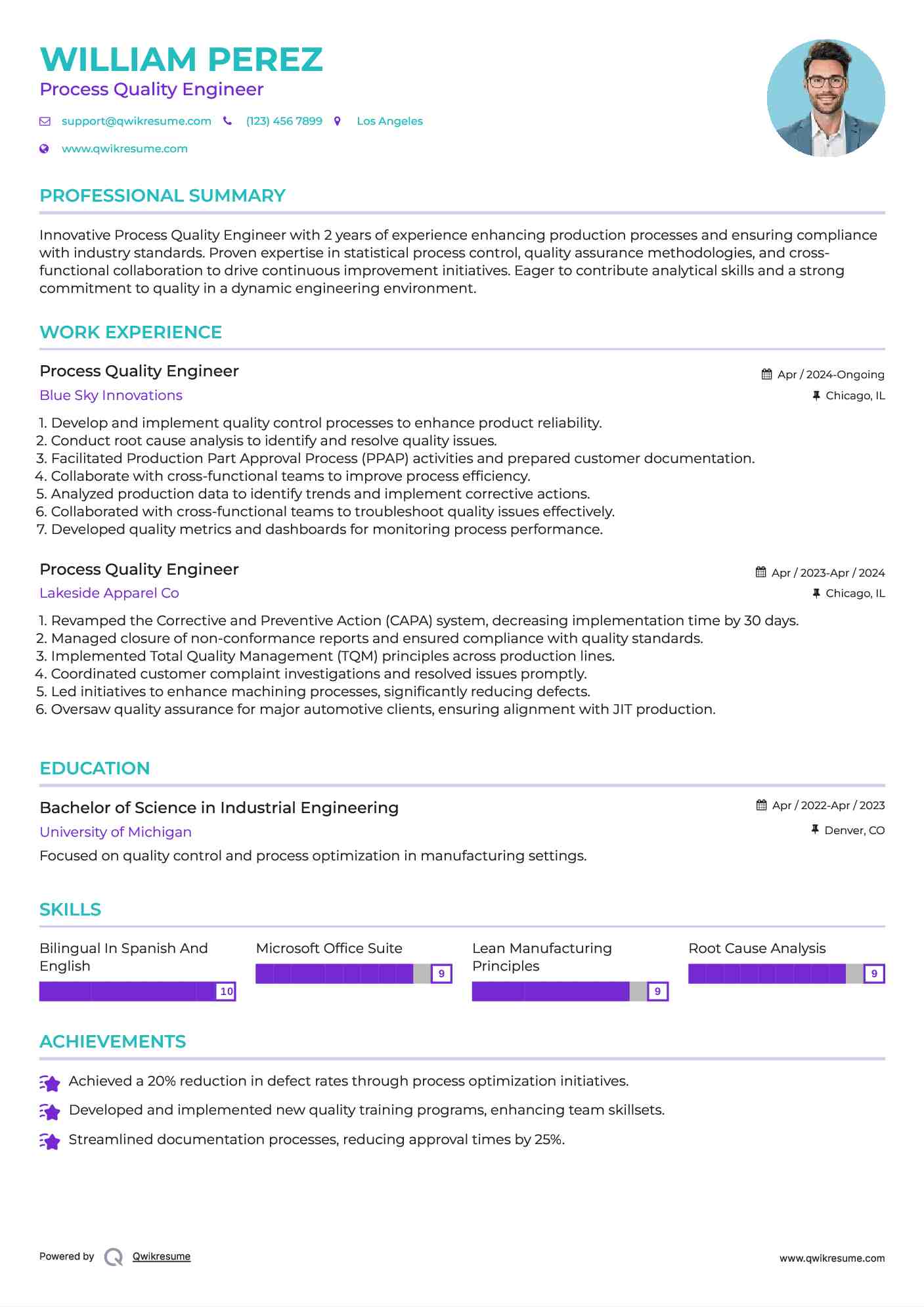

Process Quality Engineer Resume

Objective : Highly skilled Process Quality Engineer with four years of experience improving safety, quality, profitability and processes within the automotive manufacturing industry. Demonstrated ability to design for manufacturability and implement quality standards.

Skills : Bilingual Spanish-English, Microsoft Office, Lean Manufacturing,.

Description :

- Designed, technical management, coordination, monitoring, and control of the project.

- Monitored control plans to report results to the directors of the company.

- Identified the unbalance as well as the qualitative losses.

- Increased OEE from 15% to 75% and quality sigma level to 4.7.

- Reduced process scrap by optimizing process parameters using Response Surface DoE.

- Facilitated PPAP activities and prepare customer documentation and review as required.

- Ensured successful program launches and change control coordination.

Experience

2-5 Years

Level

Executive

Education

MS

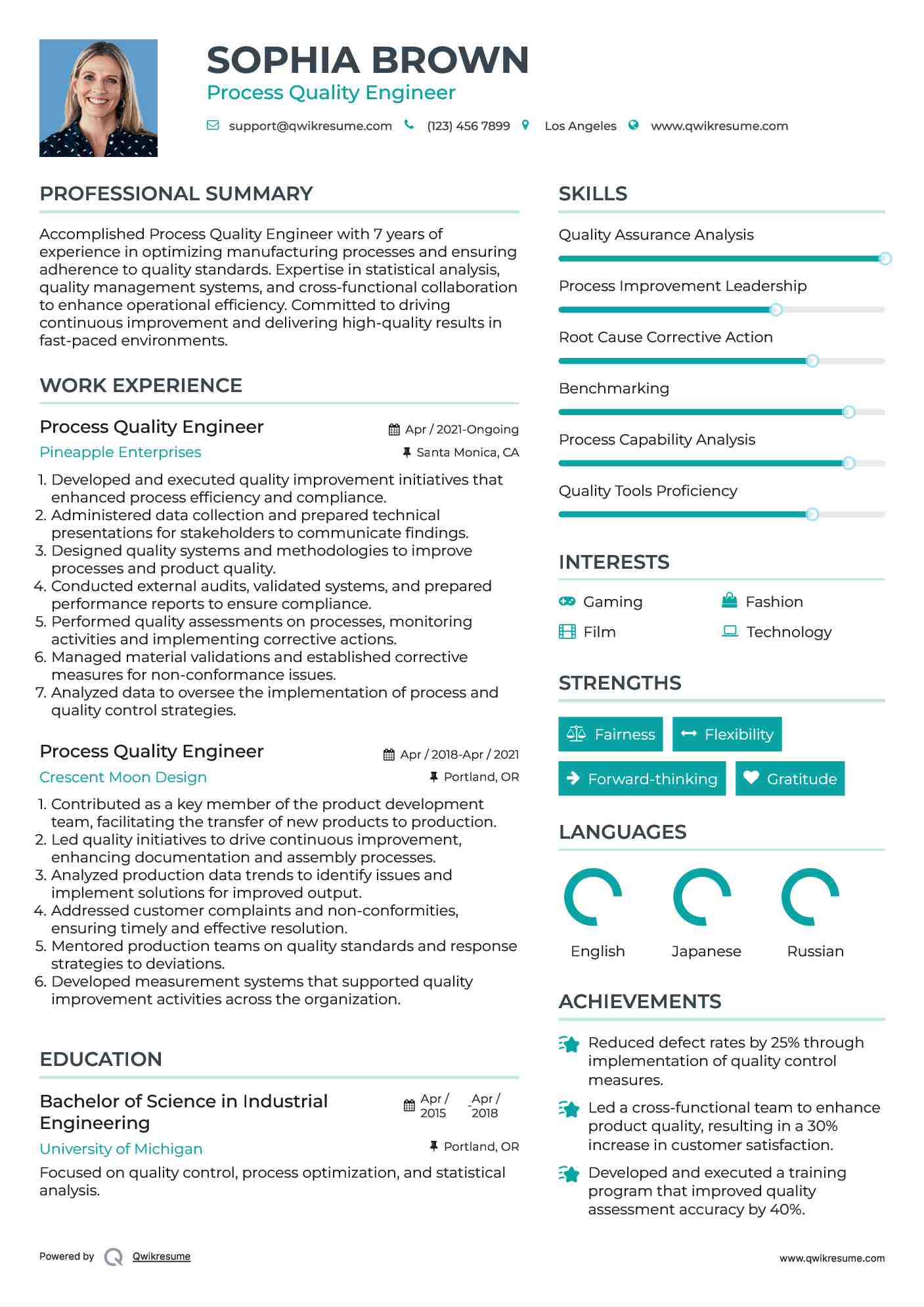

Process Quality Engineer Resume

Headline : Responsible for Reviewing and assuring compliance with customer blueprints, specifications, and other technical documents, Assisting manufacturing in performing studies to establish the effectiveness of gaging and to determine process capability and control (Gage R&R/MSA).

Skills : Communication SKills, Management SKills, MS Office.

Description :

- Improved the process, quality, safety, and logistics of the assembly line through several projects at the same time in a fast-paced environment.

- Evaluated project feasibility: cost, timing, human resources, necessities, targets, KPIs.

- Designed, technical management, coordination, monitoring, and control of the project.

- Monitored control plans to report results to the directors of the company.

- Identified the unbalance as well as the qualitative losses.

- Actively participated and assisted manufacturing to ensure quality requirements are in compliance in daily operations.

- Investigated customer concerns, develop containment activities, and coach the 8D team in the implementation of both process and system countermeasures.

Experience

5-7 Years

Level

Executive

Education

Diploma

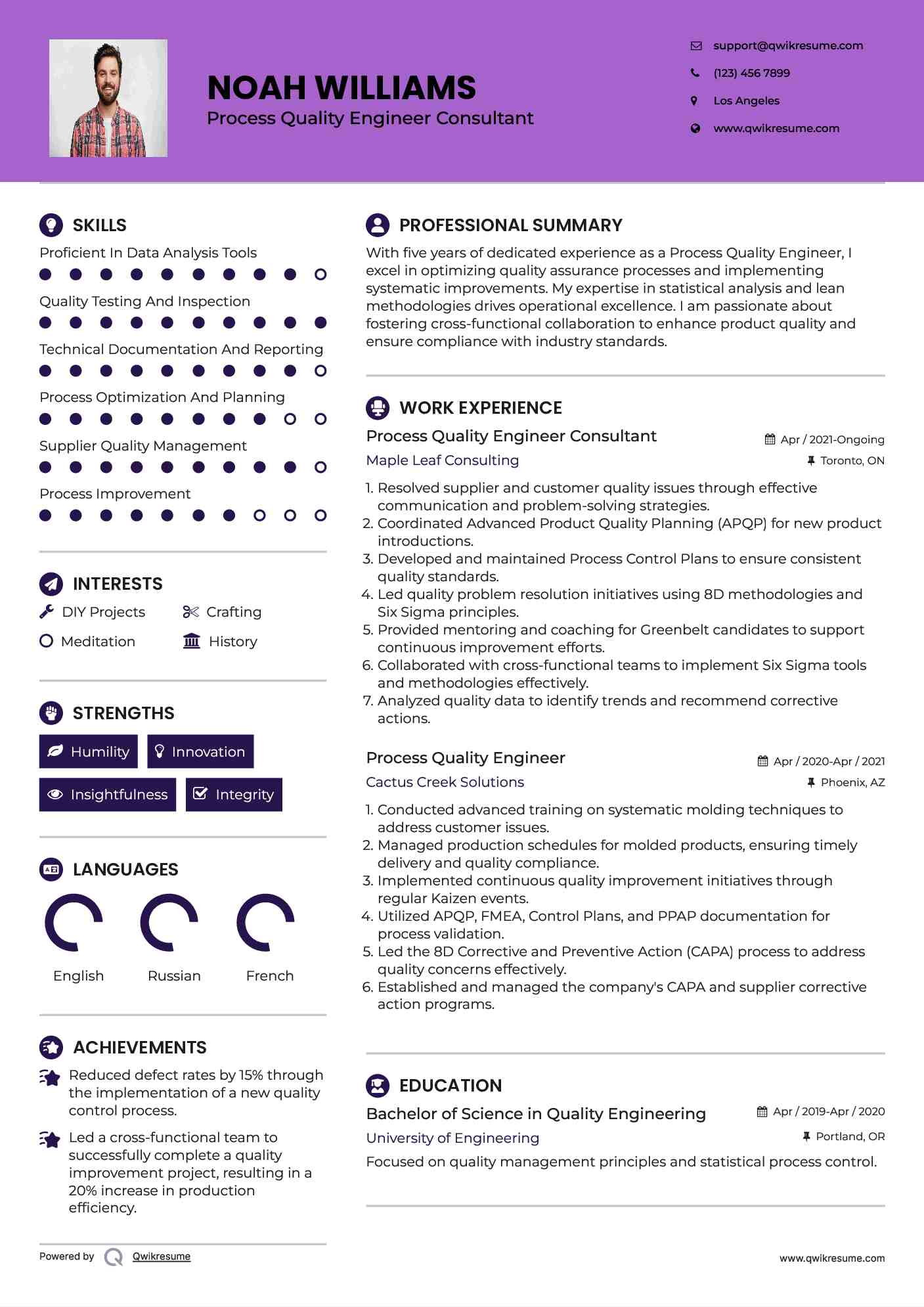

Process Quality Engineer Resume

Headline : To obtain a leadership Process Quality Engineer position that utilizes my years of management experience and my analytical experience. Proficient working knowledge of Distribution Center, Logistics Operations, Warehouse Inventory Systems, and Inventory Audit process in dry, perishable, and frozen environments.

Skills : Administrative Assistant, Executive Management, Functional.

Description :

- Developed and executed various improvements to the Quality process and develop new processes on the same.

- Administered collection of data, prepare technical presentations for customers and management.

- Developed and executed quality systems and design methods to improve or enhance the process.

- Performed external audits and validate systems, establish critical processes, and prepare reports for performance.

- Performed quality assessments for process and monitor all activities for measuring processes.

- Managed and validated all materials and establish corrective actions for any non conformance.

- Analyzed data and monitored the implementation of al Process and Quality Control Strategy.

Experience

5-7 Years

Level

Entry Level

Education

MS

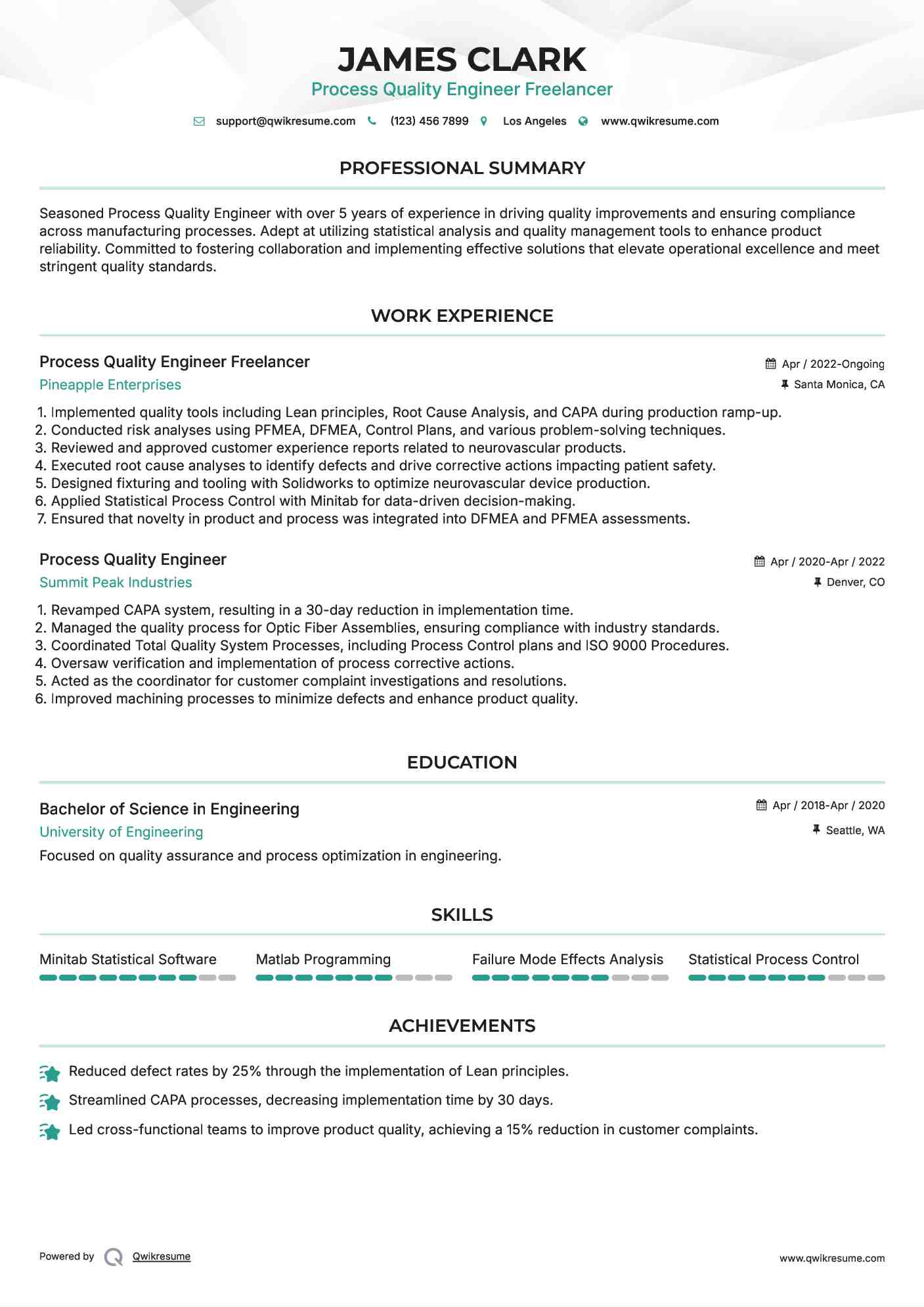

Process Quality Engineer Resume

Objective : Highly qualified Process Quality Engineer with experience in the industry. Enjoy creative problem solving and getting exposure on multiple projects, and would excel in the collaborative environment on which your company prides itself.

Skills : Proficient in Microsoft Office, Minitab, Instron Tensile Testing, Technical Writing Intermediate SolidWorks, Production Planning, Material Purchasing And Procurement, Quality Assurance.

Description :

- Reviewed and Improved quality systems.

- Resolution of Supplier and Customer Quality Issues.

- Coordinated new product introduction (APQP) thru Powerway.

- Developed Process Control Plan Responsible for Quality Problem resolution thru 8D's Six Sigma Black Belt Performed Greenbelt training to support local and regional training requirements.

- Performed Greenbelt Mentoring / Coaching.

- Directed Greenbelt in the correct application of DMAIC tools and techniques.

- Worked with all Functional Departments to ensure successful application of the Six Sigma tools and methodologies.

Experience

2-5 Years

Level

Junior

Education

GED

Process Quality Engineer Resume

Objective : Seeking a Process Quality Engineer profession with an outstanding career opportunity that will offer a rewarding work environment along with a winning team that will fully utilize management skills.

Skills : Microsoft Office, Matlab, Solid Edge, Solid Works, Unigraphics, Maple, AutoCAD, Lean/ Six Sigma certified, FMEA, Ladder Logic, GD&T.

Description :

- Reviewed and Improved quality systems.

- Planned and evaluated process conformance and perform quality audits for various business processes.

- Provided support to hardware and software designs and resolve all manufacturing issues and ensure process improvement.

- Received Quality Grand Prix award for quality systems developed and implemented during the launch of caliper machining, plating, and assembly processes.

- Acted as a technical resource for manufacturing by providing quality expertise to lead the development of APQP documentation.

- Established robust and repeatable process parameters.

- Identified and assessed quality performance and trends, investigating the root cause, implementing corrective actions, and improving assembly related.

Experience

2-5 Years

Level

Executive

Education

GED

Process Quality Engineer Resume

Objective : Process Quality Engineer with 5+ years of experience in Working as required with a customer or supplier representatives to assure all quality requirements are satisfied to Get qualified by the customer to act as a Delegated Product Release Verification personnel for multiple products.

Skills : Solidworks, Minitab, Matlab, Mechanically Inclined.

Description :

- Implemented quality tools such as Lean principles, Root Cause Analysis, and Corrective/Preventative Action (CAPA) in high volume work and during production ramp-up.

- Analyzed risk using PFMECA/DFMECAs, Control Plans, and various problem-solving approaches.

- Investigated and approved customer experience reports with returned neurovascular products.

- Determined defect with root cause analysis, impact on the patient, and corrective action implementation.

- Developed fixturing and tooling using Solidworks to aid in the production of neurovascular devices.

- Utilized Statistical Process Control with Minitab to make data-driven decisions.

- Ensured that novelty on product and process are taken into account in DFMEA, PFMEA, DV&PV

Experience

2-5 Years

Level

Junior

Education

MS

Process Quality Engineer Resume

Objective : Responsible for Using appropriate statistical tools such as collecting and summarizing data, drawing conclusions with confidence, determining sample sizes, applying data distributions, identifying relationships between variables, reliability, design, and analysis of experiments, and statistical decision making.

Skills : Continuous Improvement, Lean Six Sigma.

Description :

- Ensured quality standards in production lines: inspection, training, audits, CAPA, complaint, and non-conformance investigations, among other functions in the following technical areas: coating, assembly, sterile pack, and electrical tests to manufacture 10+ categories of two products.

- Led a team in quality program implementation for product transfer.

- Performed Product, Process, Biocompatibility, and Sterilization qualifications.

- Supervised two technicians and 12 inspectors.

- Acted as a Supplier Quality Engineer (Incoming Inspection Supervisor) for six months supervising five people.

- Planned and executed inspection schedules based on customer's priorities and approved supplier and inspection documentation.

- Managed hundreds of investigations successfully resulting in process improvement avoiding reoccurrence.

Experience

2-5 Years

Level

Executive

Education

BS In Electrical Engineering

Process Quality Engineer Resume

Headline : Seeking a Process Quality Engineer position, responsible for Participating in cross-functional teams in the investigation and elimination of causes of quality problems and follow-up on corrective actions.

Skills : Ms. Office Suite, Ms. Project, MS Visio, AutoCAD, Baan, SAP, Minitab, ProModel 7.

Description :

- Responsible for leading process quality team for tubing, printing, and injection molding lines for 5 different customer products.

- Executed IQ/OQ/PQ for new machines and tooling to ensure the transition to the production team.

- Implemented SPC limits for customer CTQ's and developed PFMEA for new processes.

- Performed root cause analysis and implementing corrective and preventive actions on consumer quality issues.

- Ramped up production for a key account by adding 30% capacity of plant's volume.

- Result: Produced 15,000,000 tubes per month.

- Improved OEE and increased quality level in the medium speed tubing line.

Experience

5-7 Years

Level

Junior

Education

MS In Industrial Engineering

Process Quality Engineer Resume

Headline : Hardworking, organized, Process Quality Engineer professional with a proven background delivering sensible business technology solutions on time and under budget while working as a team member or team leader.

Skills : Negotiation, MRP, ERP, Supply Chain, Supplier Relationship Management, Cost Out, Planning, Purchasing, Continuous Improvement, Inventory Management.

Description :

- Provided assurance that appropriate metrics are collected, analyzed, reported and trended over time to assure continual improvement.

- Provided assurance that the calibration program at BAS is compliant with ISO 9001 requirements.

- Optimized the process for identifying equipment requiring calibration and assuring that this equipment is calibrated on time.

- Led PFMEA meetings and create supporting documents Conferring with Design Engineering to provide input concerning new product designs to help assure quality and safety is built into all BAS products by concentrating on GD&T and identifying critical characteristics of new products.

- Created SolidWorks models and drawings for mechanical fixtures and other items needed on the production line.

- Conducted internal audits to proactively identify and correct non-compliances within BAS processes.

- Evaluated BAF documented procedures and assure they are complete, accurate, and are being followed.

Experience

5-7 Years

Level

Executive

Education

BS

Process Quality Engineer Resume

Headline : Process Quality Engineer Professional with expertise in the implementation and improvement of quality management systems in a manufacturing environment. Identifies and implements improvements to supply chain processes, and quality management systems for new products and facilities. Welcomes opportunities to continue to learn and expand skill set to add value for the company.

Skills : Lean Thinking, Statistical Analysis, 5S, Six Sigma, Continuous Improvement, Economic Analysis, SPC.

Description :

- Defined requirements to maximize safety, throughput, and quality of the processes.

- Optimized yield and minimized scrap materials.

- Implemented statistical process analysis in manufacturing processes.

- Managed the cost and time constraints of projects.

- Worked with chemical engineers to improve efficiency.

- Developed skills in plastic extrusion, injection molding, and coating processes.

- Reviewed Failure Modes and Effects Analysis (FMEA).

Experience

5-7 Years

Level

Executive

Education

Diploma