Product Development Engineer Resume

Objective : Over 30 years of engineering experience, working on everything from complex test equipment to a communication system for the Space Shuttle, development company, offering my expertise in robotics, product development, software, hardware, and test engineering to companies such as Ugobe Life Forms, Sapidyne Instruments, Pulse Robotics, BlueRail Trains, and BOCOLAB.

Skills : Mechanical And Engineering, Drafting 3D, Sales Engineering.

Description :

- Performed testing of vacuum and atmosphere heat treat furnaces.

- Supervised metallurgic testing of furnace output, and provided subsequent documentation of related findings.

- Provided customer relations and instruction on the proper maintenance of equipment.

- Completed an in-depth study of the performance differences between a salt bath heat treat process and vacuum heat treat process.

- Completed a study comparing electrically heated and gas fired heat-treating in cooperation with East Ohio Gas of Cleveland.

- Improved existing process at an aluminum brazing facility of a major manufacturer of automobile cooling components.

- Tested and evaluated furnace operation of deoiling sequences in brazing furnaces and furnace operation of new gas fired vacuum heat-treating furnaces.

Experience

2-5 Years

Level

Junior

Education

Mechanical Engineering

Sr. Product Development Engineer Resume

Summary : To obtain a position that will enable me to use my strong design skills, my ability to work well with people, where my experience can be utilized to push projects further, all while gaining experience in an office environment and in the field of architecture.

Skills : Autocad, Revit, Rhinoceros, Illustrator, Product Development, Product design, Photoshop, Microsoft office, Content Creation.

Description :

- Supervised 2 technicians and 16 hourly union personnel.

- Working in Quality Control department with responsibility for production of annual, weekly and monthly projects.

- Including developing and implementing supplier quality management for incoming raw materials including stains and other raw materials by developing a Quality System (QS) for sourced materials including developing test procedures and specifications.

- Predict production characteristics of raw materials, additives, compounds, and glazes.

- Supervise testing of finished products to meet prescribed standards.

- Responsible for delivering approved and corrected glazes to the production lines.

- Developed new products to increase market share.

- Troubleshoot and solve production problems related to the manufacturing of products.

Experience

10+ Years

Level

Senior

Education

Ceramic Engineering

Jr. Product Development Engineer Resume

Objective : Mechanical engineering professional with experience in complex dynamic assemblies. Background and specialties lies in the automotive and motorsports industries and executive leadership. Interested in making significant contributions to the future of your company utilizing my engineering experience and leadership capabilities, while continuing to learn with the brightest minds in the industry.

Skills : SolidWorks, Pro-E, SmarTeam, Windchill, Limited SAP, Microsoft Office Programs.

Description :

- Lead and managed a new project for knee implants and instruments.

- System consisted of a standard bank of over 150 implants in addition to instruments specific to the system for various surgical techniques.

- Responsible for casting, machined, and catalog prints for femoral, tibial, insert, and patella components.

- Developed an Instrument Upgrade for the EPIK Uni-compartmental Knee including Verification, Validation, and Manufacturing Transfer, which allowed Encore to achieve a greater portion of the market share.

- Completed Manufacturer of Record Transfer for an acquired product line from OTI, including documentation and drafting transfers to incorporate into the Encore Quality System.

- Additionally, worked diligently to develop a set of special instruments for the acquired product line in order to retain one of the top volume surgeons in the company.

- Delegated drafting and documentation requests to drafters and co-op students based upon capability and resource constraints.

- Designed improvements to the 3D Knee System for tibial downsizing capabilities as well as femoral impaction instrumentation to meet international requests for a clearer and less complicated surgery.

Experience

2-5 Years

Level

Junior

Education

B.S. In Mechanics

Product Development Engineering Manager Resume

Headline : Passionate innovator with product design, engineering support, quality testing, and program management experience derived from years in the aerospace, telecommunications, consumer electronics, and entertainment industries. Driven problem solver who thrives in diverse environments and has a proven record of delivering results under pressure.

Skills : Engineering, Welding, Design, Microsoft Office, Autocad, Solidworks, Mac.

Description :

- Design and develop new product for truck and SUV vehicles.

- Develop 3-D cad model of parts using Solidworks.

- Develop prototypes using plasma cutter and worked closely with fabricator.

- Conduct product design validation and verification for production.

- Produce engineering drawings for fabricator and create bill of materials for manufacturing.

- Worked closely with overseas vendors on production manufacturing.

- Conducted finite element analysis on various trailer hitch classes per SAE J684, using Solidworks simulation.

Experience

5-7 Years

Level

Executive

Education

Mechanical Engineering

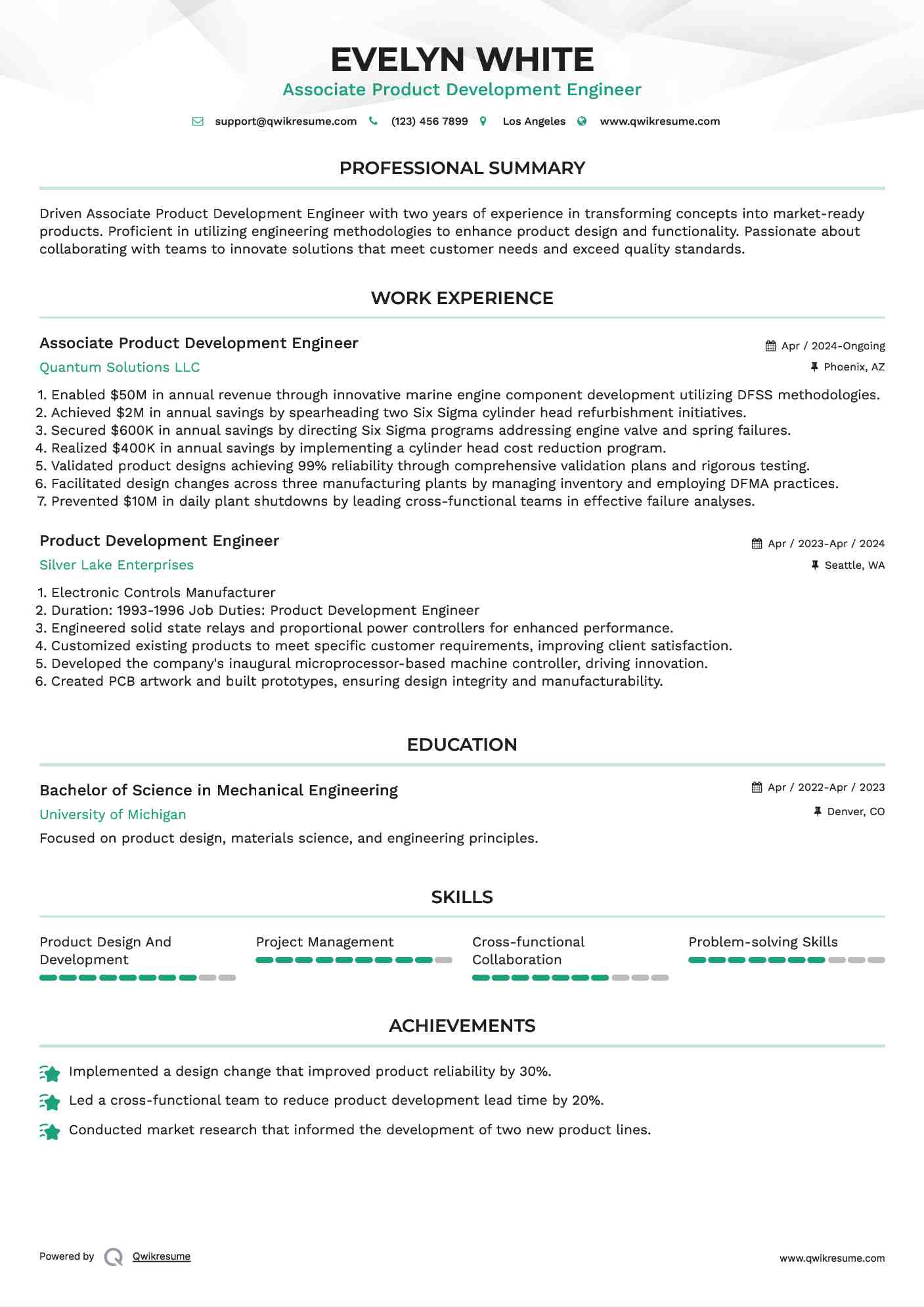

Associate Product Development Engineer Resume

Summary : Creative Manufacturing/Mechanical Engineer with experience in process engineering, new product development, product performance and reliability evaluation, quality systems implementation and auditing. Lean Methodology expert with good command over concepts and methodology of Six Sigma for process Design and improvement, and control of manufacturing Systems Excellent in designing (DOE) and conducting experiments; Hands-on experience and skills on statistical data analysis.

Skills : Manufacturing, Process Engineering, Technical Services, Product Development, Continuous Improvement, Customer Service, Materials.

Description :

- Developed products for home care, baby care & beauty care using the various technologies available within the company.

- Individual products taken from inception to commercialization.

- Directed development programs resulting in over $3.5 million in sales revenue.

- Managed cost savings projects achieving $35K in savings annually.

- Participated in the start-up of new and upgraded commercial production lines.

- Managed multiple domestic and international projects simultaneously.

- Received outstanding commendations for commitment to customers, attention to detail, professionalism and follow-up.

- Technical Services Manager Worked for a group within PGI that serviced a specific high profile customer to foster improved relationships via problem solving techniques of converting and/or performance issues.

Experience

10+ Years

Level

Senior

Education

Diploma

Product Development Engineer I Resume

Objective : Innovative product development leader, who engages with internal and external resources, to convert ideas into revenue generating programs. Adept at identifying and analyzing technologies to generate business opportunities and develop high performance engineering teams to successfully commercialize products.

Skills : Researching And Developing New Technologies, Business.

Description :

- Product Development and Cost Reduction Enabled $50M annual revenue by developing marine engine components using DFSS.

- Achieved $2M annual savings by leading 2 Six Sigma cylinder head refurbishment programs.

- Obtained $600K annual savings by leading Six Sigma engine valve and spring failure programs.

- Saved $400K annually by leading cylinder head cost reduction program.

- Validated designs for 99% reliability via validation plans, design reviews, and testing.

- Implemented design changes at 3 manufacturing plants by managing inventory and performing DFMA.

- Plant Support Avoided $10M/day plant shutdowns by leading cross functional teams to perform failure analyses.

- Made expedited decisions by analyzing data from FTIR, scanning electron microscope, X-Ray diffraction, dimensional analyses, chemical and metallurgical tests and engine tests.

Experience

2-5 Years

Level

Junior

Education

M.B.A.

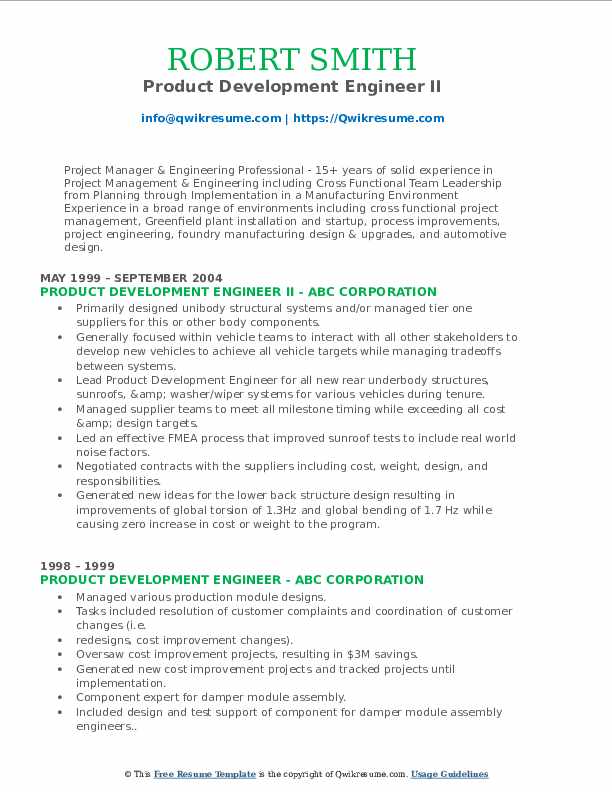

Product Development Engineer II Resume

Summary : Project Manager & Engineering Professional - 15+ years of solid experience in Project Management & Engineering including Cross Functional Team Leadership from Planning through Implementation in a Manufacturing Environment Experience in a broad range of environments including cross functional project management, Greenfield plant installation and startup, process improvements, project engineering, foundry manufacturing design & upgrades, and automotive design.

Skills : Solidworks, autodesk inventor, Solid Edge, geomagic, 3d scanning, Finite element analysis, Matlab, optimum kinematics, six sigma, Motec I2 Pro, Aim Race Studio Plus, Mastercam, TIG Welding, Lathing, Milling.

Description :

- Primarily designed unibody structural systems and/or managed tier one suppliers for this or other body components.

- Generally focused within vehicle teams to interact with all other stakeholders to develop new vehicles to achieve all vehicle targets while managing tradeoffs between systems.

- Lead Product Development Engineer for all new rear underbody structures, sunroofs, & washer/wiper systems for various vehicles during tenure.

- Managed supplier teams to meet all milestone timing while exceeding all cost & design targets.

- Led an effective FMEA process that improved sunroof tests to include real world noise factors.

- Negotiated contracts with the suppliers including cost, weight, design, and responsibilities.

- Generated new ideas for the lower back structure design resulting in improvements of global torsion of 1.3Hz and global bending of 1.7 Hz while causing zero increase in cost or weight to the program.

Experience

7-10 Years

Level

Consultant

Education

Master Of Science

Product Development Engineer III Resume

Summary : Industry Development Experience: Database, Web, Accounting/General Ledger, Warehouse, Tax, Lab/QA, OPC, Embedded Systems, PLC, Communication Drivers/Protocols, Business Intelligence, EDI, and Wireless. Database Systems: SQL Server, Oracle, and Access. Network Design and Implementation: wired, fiber, and wireless.

Skills : Python, HP Quality Center, Microsoft Office, Engineering.

Description :

- Developed a script language, field support utilities, and several graphics tools to implement a company's products with a touch screen system.

- Initiated and developed a feature that simplified and automated the configuration of new tank monitoring products.

- Developed a nationally distributed Windows based software package that collects inventory, EPA compliance, and equipment alarm data for retail petroleum stations.

- Maintained and enhanced a telecommunication-based host to monitor over 150 remote stations.

- Designed, constructed, and tested quad-safety barriers; prepared the circuit assemblies for production and UL approval.

- Participated in team efforts to design automatic tank/line testing systems for retail petroleum outlets.

- Provided assistance and training for installation contractors and end users of the company's compliance products.

- Modified a company product to use a much lower cost touch-screen.

Experience

7-10 Years

Level

Consultant

Education

Electrical Engineering

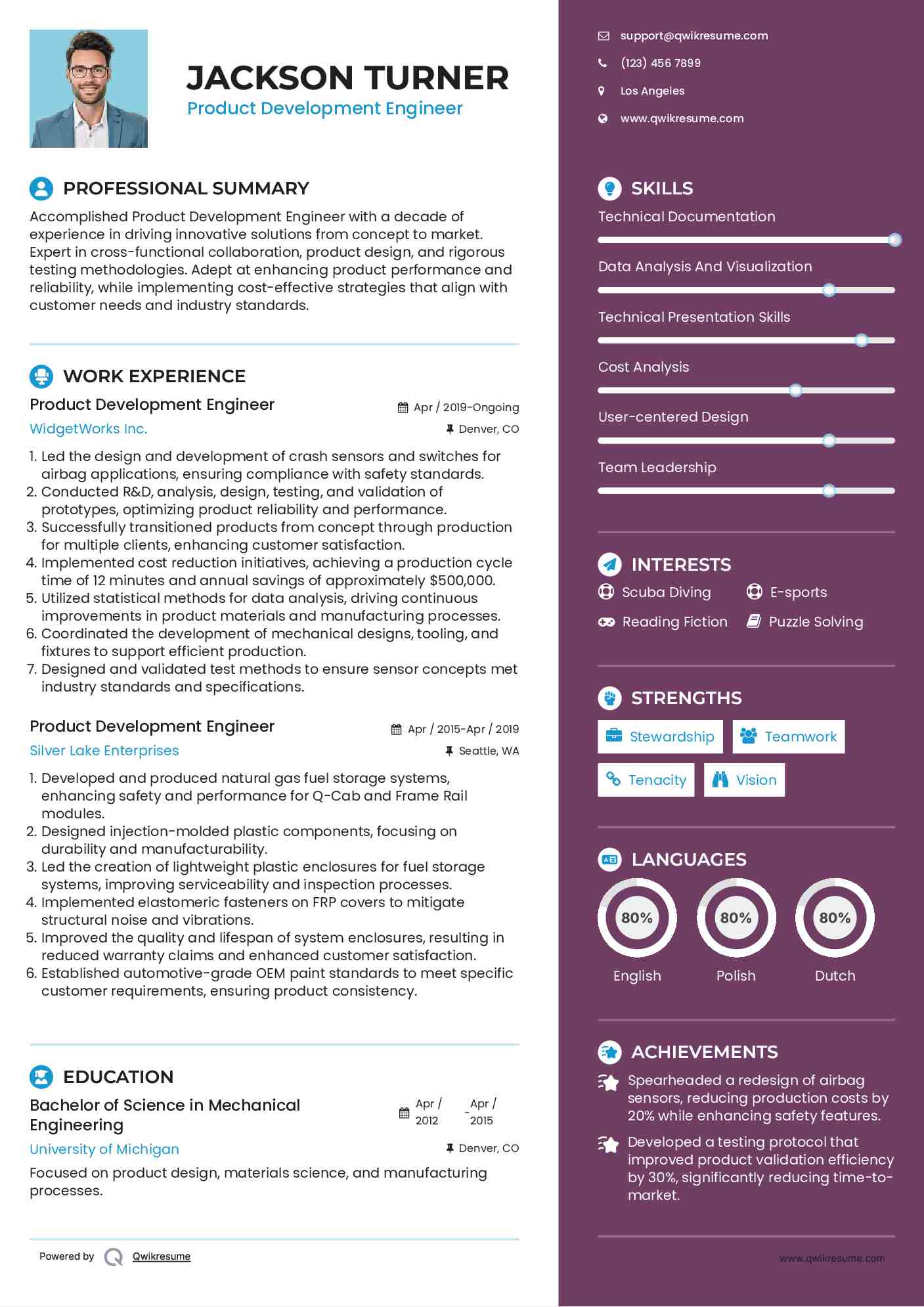

Product Development Engineer Lead Resume

Objective : Seeking out new challenges within the company in need of someone with exceptional planning, leadership, and management abilities. Critical thinker, able to design problem-solving, profit maximizing methods to solve complex issues. Hard working, leadership, and taking command of an operation or project, then guiding it to new performance levels are my greatest strengths.

Skills : Econometric, Excel, power point, Word.

Description :

- Responsible for the design and development of crash sensors and switches for airbag applications, and processing them through production.

- Included research and development, analysis, design, testing, prototype construction, design validation, evaluation, product verification, product launching, and continuous improvement.

- Have taken products from design concept through production for various customers.

- Planned and participated in cost reduction programs to reduce the cycle time to produce a sensor in 12 minutes by improving product performance and process efficiency, resulting in annual savings of approximately $500,000.

- Applied statistical methods to analyze data, including gage R&R, repeatability, reliability, and correlation, for continuous improvements in materials, products, and equipment.

- Directed and coordinated the development of mechanism design, tooling and fixturing.

- Designed, developed, and determined appropriate test methods to validate sensor concepts.

Experience

2-5 Years

Level

Junior

Education

M.S.

Asst. Product Development Engineer Resume

Objective : Experienced Manufacturing professional skilled in Lean Manufacturing, Six Sigma, and Assembly processes, line layout, standardized work and process using DMAIC Methodology. Work with NPI Engineer, Procurement, Quality and Design Engineering to Successfully launch New Product Platforms. Assisting with FMEA, design changes tooling, factory floor floors layout setup. Bill of Material creates planning & routing new products for entire production.

Skills : Lean Manufacturing, Autocad.

Description :

- Selection of tooling for production assembly & conduct cost justification capital equipment.

- Design & Modify new tooling fixtures for production.

- Perform time studies, evaluate routing and efficiencies to improvement of 20% labor cost.

- Write process instruction procedure for assembly operations.

- Electronic Automation & programmed robotic material handling applications.

- Update & Correction BOM structure for Services Department.

- Engineering change request, documented properly by using ECN.

- Programmed robotics automation system power coating on microwave cavities.

Experience

2-5 Years

Level

Executive

Education

Bachelor Of Science

Product Development Engineer (Consultant) Resume

Headline : Energetic chemical engineer experienced in developing, designing, and improving new or existing products and processes. Research scientist with an emphasis on materials properties, alternatives and comparisons. Creative and dynamic resource for product and process knowledge resulting in practical solutions. Technical professional with a focus on coordinating activities with a variety of people and departments to achieve mutual goals.

Skills : Computer Programming: LabVIEW, MATLAB, C, C++, Visual C, .NET, Python.

Description :

- Design and develop test fixtures using 3D CAD software.

- Design and assemble electromechanical systems for data acquisition and control.

- Develop Labview software to monitor and control fuel processing systems for Hydrogen generation in Fuel Cells.

- Completed design, construction, and commission of a fuel cell reformer test stand to increase capacity and capability.

- Increased test capacity by 50% for fuel cell reformer development.

- Skills Used Labview programming and 3D CAD design skills.

- Applied Electromechanical assembly and data acquisition skills.

Experience

5-7 Years

Level

Consultant

Education

BS

Product Development Engineer Resume

Objective : Electrical Engineering graduate with 8+ years working experience in RF/Microwave and Defense/Aerospace manufacturing industry. Primarily focused on implementation of RF amplifiers and communication systems up to 6.0GHz. Excellent interpersonal and communication abilities and possess a wide range of technical skills and knowledge of RF theory, optimization, transmission line and devices using LDMOS, GaAs and GaN technology.

Skills : PSpice/B2Spice, MATLAB, C++ Language, Assembler Language, ETAS Software, Customer Service, CANalyzer & CAPL Scripts.

Description :

- Assisted in the design and implementation of Automated Test Equipment (hardware and software) in support of government contracted power amplifiers.

- Collected test data and performed comprehensive test data analysis from Automated Test Equipment.

- Supported new product launch by providing design validation test reports.

- Programed profile and performed Chamber and ESS test as a part of design validation tests.

- Designed and built test fixture/zig for ESS tests.

- Recognized trends and patterns in design validation test failures and feedback to the R&D team with the relevant information of short term fixes and future improvements.

- Evaluated and characterized all prototyped RF power amplifiers.

- Controlled Engineering Change Order (ECO) and RMA's for all prototyped RF power amplifiers.

Experience

0-2 Years

Level

Entry Level

Education

Bachelor Of Science

Senior Product Development Engineer II Resume

Headline : Engineering and Operations executive with significant broad-based experience in the telephone, and power management businesses. Technical background in design and support of telephones, wire, cable, cord sets and surge protection devices. Proven leadership skills and expertise in: Operations Management Project Management Department Start-Up 3PL e-Commerce Fulfillment Services Lean Inventory Control New Product Development Compliance Testing Total Quality Control Expert Witness.

Skills : Microsoft Office, Management.

Description :

- Directed consolidation and transfer of Design Engineering functions from American Electric Cordsets' Bensenville, Illinois office to Belden's Carmel, Indiana office.

- Effectively reduced the number of design engineers from three to one while improving engineering customer response time by 25%.

- Managed new product development and product changes for key company customers.

- Coordinated product design with mechanical development team to ensure high quality and low defect manufacturing.

- Identified opportunities for improvement at the Mexico factory.

- Conducted on-site training across all shifts and resolved issues that resulted in defect levels.

- Revised the product quotation department.

- Implemented an automated process utilizing a Product Configurator feature of the mainframe computer system which shortened the quotation time by 60%.

- Managed the development and implementation of a new corporate mainframe computer system and custom software packages for Design and Plant Engineering functions.

Experience

5-7 Years

Level

Executive

Education

B.S.

Associate Senior Product Development Engineer Resume

Headline : Sr. Product Development Engineer with significant experience in hardware validation, ASIC verification and UEFI BIOS programming. Skilled in co-simulation hardware and software, using Verilog and System Verilog models. In-depth knowledge of logic design concepts and debug tools such as ITP and JTAG.

Skills : CAD, FMEA, Validation, Auditing, Data Analysis, Statistical Analysis, Educator.

Description :

- Responsible for test development and post-silicon validation.

- Successfully participated in bring up of the first arrival of SB900 first silicon.

- Developed ATE test program (C/C++) for M3T chipset, and performed bring up upon arrival of first silicon.

- Worked closing with a designer in getting the target coverage of SCAN patterns.

- Performed pattern conversion and getting the SCAN patterns working in ATE.

- Performed scan diagnostic for the errors found from SCAN patterns on ATE, and subsequently feedback to design engineer in order to get the latest updated patterns.

- Worked closely with Design to fix SATA test instability issue.

- Engaged with Analog team to measure the strength of TX eye of SATA signal.

Experience

5-7 Years

Level

Executive

Education

Engineering

Senior Product Development Engineer Resume

Headline : Product Development Engineer is responsible for the engineering of new products, prototypes, and systems. This includes designing, programming, and testing the product.

Skills : Product Change Management Control, Lean and Six Sigma, Global 8D, Red X Statistical Problem Solving, Supplier Quality Processes and Documentation.

Description :

- Managed multiple projects for various customers.

- Provided initial product development phase to commercialization phase services based on the customer request.

- Designed, developed, prototype and verified the initial balloon catheters, lumen catheters, and braided shaft catheters.

- Developed design inputs, verification and validation protocols and reports, as well as other documentation necessary to support the design history file for the customer.

- Developed manufacturing process and process validation.

- Specialized in polyurethane and non-polyurethane balloons catheters.

- Performed lot release testing, DOE, PFMEA, IQ, OQ, PQ, CAPA, ECO, MRR and Product transfer to manufacturing.

- Provided status reports to supervisors, management, as well as to other team members on the various projects.

Experience

5-7 Years

Level

Executive

Education

Engineering