Production Planner Resume

Headline : With 7 years of experience in production planning, I excel in optimizing manufacturing processes and managing supply chain logistics. My strong analytical skills and proficiency in MRP systems enable me to forecast needs and streamline operations effectively. I am committed to driving efficiency and ensuring timely delivery while maintaining high standards of quality.

Skills : Production Planning, Demand Forecasting, Operational Coordination, Microsoft Office Suite

Description :

- Utilized MRP system to create master production schedules aligned with sales forecasts and inventory levels.

- Collaborated with cross-functional teams to address material shortages and adjust production timelines proactively.

- Established monthly inventory budgets for raw materials and finished goods, ensuring optimal stock levels.

- Managed the planning and scheduling of over 100 finished goods, prioritizing based on demand and capacity.

- Analyzed raw material needs and component requirements to support production goals.

- Monitored inventory for excess or obsolete items, implementing strategies to mitigate waste.

- Tracked backorders and adjusted production schedules to meet customer delivery expectations.

Experience

5-7 Years

Level

Executive

Education

B.S. Industrial Eng.

Production Planner/Scheduler Resume

Objective : Dynamic Production Planner with 5 years of experience in optimizing manufacturing workflows and enhancing supply chain efficiency. Adept at leveraging analytical skills and MRP systems to forecast production needs and streamline operations. Passionate about achieving operational excellence and ensuring timely delivery of quality products.

Skills : Erp Software Proficiency, Manufacturing Knowledge, M3 Erp Software, Adept Scheduling Software, Epdm Management Systems

Description :

- Develop and maintain production schedules to meet customer demand and optimize resources.

- Analyze production data to identify trends and improve efficiency in manufacturing processes.

- Designed and implemented an efficient scheduling system that improved workflow across departments.

- Coordinate with procurement to ensure timely availability of materials for production.

- Collaborated with department supervisors to assess project status and address potential delays.

- Generated detailed production reports, backlogs, and monthly forecasts to track performance metrics.

- Facilitated cross-departmental communication to enhance operational efficiency.

Experience

2-5 Years

Level

Junior

Education

B.S. SCM

Production Planner/Buyer Resume

Headline : Accomplished Production Planner with 7 years of expertise in enhancing operational efficiency and managing complex supply chain processes. Proficient in utilizing MRP systems for accurate forecasting and effective inventory management. Committed to optimizing production schedules to ensure timely delivery of high-quality products while driving continuous improvement initiatives.

Skills : Attention To Detail, Supply Chain Optimization, Capacity Planning, Supplier Relationship Management, Workflow Management

Description :

- Utilize ERP systems to track production progress and update schedules accordingly.

- Communicate with production teams to ensure alignment on schedules and priorities.

- Implement lean manufacturing principles to streamline production workflows and reduce waste.

- Provided rapid response to urgent customer requests for out-of-stock items, enhancing customer satisfaction.

- Participated in cross-functional continuous improvement teams to drive efficiency.

- Prepare reports on production performance metrics for management review.

- Conduct capacity planning to ensure production capabilities meet forecasted demand.

Experience

5-7 Years

Level

Executive

Education

B.S. IE

Production Planner Assistant Resume

Summary : Bringing a decade of expertise in production planning, I specialize in optimizing workflows and enhancing supply chain effectiveness. My proficiency in MRP systems and analytical acumen allows me to accurately forecast production needs, ensuring timely delivery and high-quality standards. I am dedicated to driving continuous improvement and operational excellence across all phases of the production cycle.

Skills : Performance Metrics, Mk Software Expertise, M3 Manufacturing Solutions, Adept Supply Chain Management, Epdm Process Management

Description :

- Develop and manage comprehensive production schedules to meet organizational objectives and customer demands.

- Coordinate job releases and priorities with the shop floor while optimizing resource allocation.

- Oversee material issuance from inventory and ensure accurate routing verification before production release.

- Communicate shipping priorities to ensure timely deliveries to customers.

- Monitor production progress against monthly goals and adjust plans as necessary.

- Participate in production meetings to provide status updates and resolve any operational issues.

- Collaborate with sales teams to deliver accurate lead time estimates for customer orders.

Experience

7-10 Years

Level

Management

Education

B.S. IE

Production Planner/Supply Chain Manager Resume

Summary : Seasoned Production Planner with a decade of experience in optimizing manufacturing processes and enhancing supply chain efficiency. Expertise in leveraging advanced MRP systems for precise forecasting and effective inventory management. Passionate about driving operational excellence and ensuring timely delivery of high-quality products while implementing continuous improvement strategies.

Skills : Proficient In Mrp Systems, Advanced Excel Skills, Strong Organizational Skills, Adaptable To New Technologies, Production Scheduling

Description :

- Identified and implemented operational improvements, enhancing quality and reducing costs.

- Collaborated with production teams to support efficient workflow and achieve company objectives.

- Maintained compliance with safety standards and procedures to ensure a secure work environment.

- Communicated job progress and material needs effectively to supervisors.

- Applied lean manufacturing principles to streamline processes.

- Managed supply orders to maintain optimal inventory levels.

- Utilized ERP software to track production metrics, enhancing reporting accuracy and decision-making speed.

Experience

10+ Years

Level

Senior

Education

B.S. SCM

Materials & Production Planner Resume

Summary : Experienced Production Planner with a decade of expertise in optimizing manufacturing processes and enhancing supply chain efficiency. Proficient in MRP systems and data analysis, I effectively forecast production needs and streamline operations. Committed to achieving on-time delivery while maintaining exceptional quality standards and driving continuous improvement across all production phases.

Skills : Expert In Sap, Advanced Microsoft Office Skills, Highly Organized, Adaptable And Quick Learner

Description :

- Coordinate the procurement of electronic components for military contracts, ensuring compliance with customer specifications and BOMs.

- Utilize Excel for tracking orders and managing inventory levels to prevent production delays.

- Expedite parts and sub-assemblies through all production departments to meet tight deadlines.

- Develop and maintain assembly travelers, ensuring adherence to current print revisions.

- Release production orders and schedule sub-assemblies in collaboration with department supervisors.

- Oversee kitting processes to ensure timely availability of components for assembly.

- Facilitate the final assembly process by coordinating with Test and Inspection departments to meet shipping schedules.

Experience

10+ Years

Level

Senior

Education

B.S. IE

Production Planner/Coordinator Resume

Summary : Accomplished Production Planner with a decade of experience in streamlining production operations and enhancing supply chain logistics. Expert in utilizing MRP systems for precise forecasting and efficient resource allocation. Committed to driving continuous improvement and ensuring on-time delivery of high-quality products, all while maximizing operational efficiency.

Skills : Production Reporting, Process Improvement Strategies, Sap Erp Systems, Syteline Erp Management, Matrix Management

Description :

- Developed detailed production schedules to align with sales forecasts, ensuring timely fulfillment of customer orders.

- Optimized workflow processes to improve operational efficiency and reduce production costs.

- Utilized MRP systems to monitor inventory levels and forecast material requirements.

- Coordinated with various departments to adjust production plans based on real-time operational changes.

- Generated comprehensive status reports for upper management, tracking job progress from initiation to completion.

- Identified and communicated schedule discrepancies to management, facilitating timely corrective actions.

- Conducted post-production evaluations to ensure all costs were captured accurately before job closure.

Experience

7-10 Years

Level

Management

Education

B.S. IM

Senior Production Planner Resume

Summary : Accomplished Production Planner with a decade of extensive experience in optimizing production schedules and enhancing supply chain logistics. Expert in utilizing MRP systems for precise forecasting and resource allocation, ensuring timely delivery of high-quality products. Driven to implement innovative solutions that elevate operational efficiency and support continuous improvement initiatives.

Skills : Sap Erp, Inventory Optimization, International Trade Regulations, Communication Skills, Negotiation Skills

Description :

- Skillfully negotiated contracts with vendors and suppliers to secure optimal pricing and quality for production materials.

- Managed production schedules to ensure alignment with contract requirements, budgets, and timelines.

- Developed strong relationships with suppliers and customers globally to enhance collaboration and efficiency.

- Coordinated workflow across departments and factories to expedite production processes.

- Monitored performance metrics, proactively addressing any delays impacting sales and inventory.

- Ensured timely shipments from international vendors to distribution centers, maintaining supply chain fluidity.

- Utilized JESTA software to maintain accurate cost records for materials, fostering strong vendor relationships.

Experience

7-10 Years

Level

Management

Education

B.S. IE

Junior Production Planner Resume

Objective : Results-oriented Production Planner with 5 years of experience in enhancing manufacturing efficiency and optimizing supply chain processes. Skilled in utilizing MRP systems for accurate forecasting and resource allocation. Committed to ensuring timely production schedules and high-quality standards while driving continuous improvement initiatives.

Skills : Lean Manufacturing, Inventory Management, Process Optimization, Supply Chain Coordination, Quality Control

Description :

- Analyze production documents and monitor processes to ensure compliance with standards.

- Review production schedules and work orders to determine material and staffing requirements.

- Record production metrics, including volumes produced and raw material usage.

- Compile status reports on production rates, material inventory, and customer information.

- Coordinate with logistics to manage material flow and inventory levels.

- Conduct quality assurance checks to ensure products meet specifications.

- Assist in research and development projects to enhance production processes.

Experience

2-5 Years

Level

Junior

Education

B.S. IE

Production Planner/Manager Resume

Summary : With a decade of experience in production planning, I have consistently optimized manufacturing processes and enhanced supply chain efficiency. My expertise in MRP systems and data analysis allows me to forecast production needs accurately, ensuring timely delivery of high-quality products. I am passionate about fostering continuous improvement and operational excellence in every aspect of production.

Skills : Scheduling Software Expertise, Project Management, Workflow Analysis, Statistical Analysis

Description :

- Analyze customer orders and forecast demand to inform production scheduling.

- Participated in interdepartmental team meetings to coordinate activities for multimillion-dollar manufacturing lines.

- Served as purchasing manager during the relocation of a major manufacturing line, ensuring minimal downtime.

- Received recognition from customer service for exceeding delivery commitments and enhancing customer satisfaction.

- Collaborated with international suppliers in manufacturing development planning meetings to streamline operations.

- Evaluated shop floor data software needs and recommended new division-wide software purchases for improved efficiency.

- Led weekly production meetings to align resources, improving communication and reducing downtime by 12%.

Experience

7-10 Years

Level

Management

Education

B.S. IE

Production Planner/Associate Resume

Headline : Strategic Production Planner with 7 years of experience in enhancing operational workflows and optimizing supply chain logistics. Expert in utilizing MRP systems for precise demand forecasting and inventory control. Focused on improving efficiency and ensuring on-time delivery of quality products, I am dedicated to driving continuous improvement initiatives across all production stages.

Skills : Material Requirements Planning, Cost Reduction Strategies, Customer Service Orientation, Technical Documentation, Training And Development

Description :

- Optimized order release processes using AS400 and WMS to enhance workflow efficiency.

- Prioritized tasks based on SLA agreements to improve customer satisfaction.

- Monitored outbound operations and adjusted workflows to meet production demands.

- Investigated and resolved issues with invalid containers and product discrepancies.

- Executed special projects to enhance operational efficiency as directed by management.

- Collaborated with warehouse leadership to adjust staffing based on workload requirements.

- Troubleshot RF device issues, ensuring minimal downtime in operations.

Experience

5-7 Years

Level

Executive

Education

B.S. IE

Production Planner Resume

Summary : Proficient Production Planner with 10 years of experience in refining manufacturing processes and optimizing supply chain operations. Skilled in utilizing MRP systems for accurate demand forecasting and resource allocation. I am dedicated to enhancing operational efficiency and ensuring timely delivery of high-quality products through innovative solutions and continuous improvement.

Skills : Mrp Systems Expertise, Continuous Improvement, Resource Allocation, Scheduling Software, Manufacturing Processes

Description :

- Plan, control, and monitor production programs according to sales orders, ensuring alignment with demand forecasts.

- Prepare purchase requisitions based on MRP 800 part numbers, optimizing procurement processes.

- Supervise production staff and generate comprehensive production analysis reports.

- Program and monitor shipments of materials in transit to ensure timely delivery.

- Oversee warehouse staff to maintain accurate inventory cycle counts and reduce discrepancies.

- Prepare status reports and manage work order systems within MRP using AS400.

- Created detailed production reports for management, facilitating data-driven decision-making and strategic planning.

Experience

7-10 Years

Level

Consultant

Education

B.S. IE

Senior Production Planner/Analyst Resume

Objective : To obtain a Senior Production Planner position that utilizes team building, technical and leadership skills to the best; ability in getting the job done in most accurate, efficient and timely manner possible.

Skills : Lean Six Sigma, Lab Manager For Electrostatic Discharge Sensitive Hardware, Continuous Improvement Team Member.

Description :

- Trained & verified Personnel to process, inspect, and repair various circuit boards in the microelectronics section of Richmond works.

- Provided on the job training for inspectors and repairpersons in the Backplanes IBU.

- Ordered necessary tooling and assist engineering to resolve quality issues.

- Ordered supplies, coordinate weigh, and sort and pick up defective material, pick up and deliver material throughout the factory.

- Cleaned and maintained C-processor machine, operate pumice scrubber, use hand motorized powered hand Truck & fork lift, pump chemical in and out of machines, and take sample of chemicals to the lab for analysis and plot results.

- Handled hazardous & non-hazardous waste, measure the viscosity of ink, enter work into CRT, inventory product.

- Assisted operator setup machine to ensure quality product, relieve operators for lunch and breaks.

Experience

2-5 Years

Level

Junior

Education

Administration

Senior Production Planner II Resume

Headline : Over 18 years of experience managing/planning high technology manufacturing environments with experience ranging from Production, Production Management to Supply Chain Management. Bring a strong global perspective, strong cross-functional interaction ability, strong accountability for delivering results and solutions, as well as a formidable blend of experience and education.

Skills : Management, Organizing.

Description :

- Scheduled and directed manufacturing to achieve consistent results.

- Increased on-time delivery by 25 percent in 2 year period.

- Scheduled final product for assembly and delivery.

- Developed strong leadership skills between working departments.

- Planned and controlled the material and the master production schedule.

- Liaised between multi-plant planning, purchasing and manufacturing departments, internal sales, and manufacturing assembly.

- Reviewed/authorized customer order change requests and communicated/assist- ed in resolving inadequate customer order lead time.

- Maintained and communicated weekly multi-plant delivery, missed shipments, and assembly load reports along with monthly shipment forecast and inventory levels.

- Supported materials manager in accomplishing all departmental goals.

Experience

5-7 Years

Level

Executive

Education

General

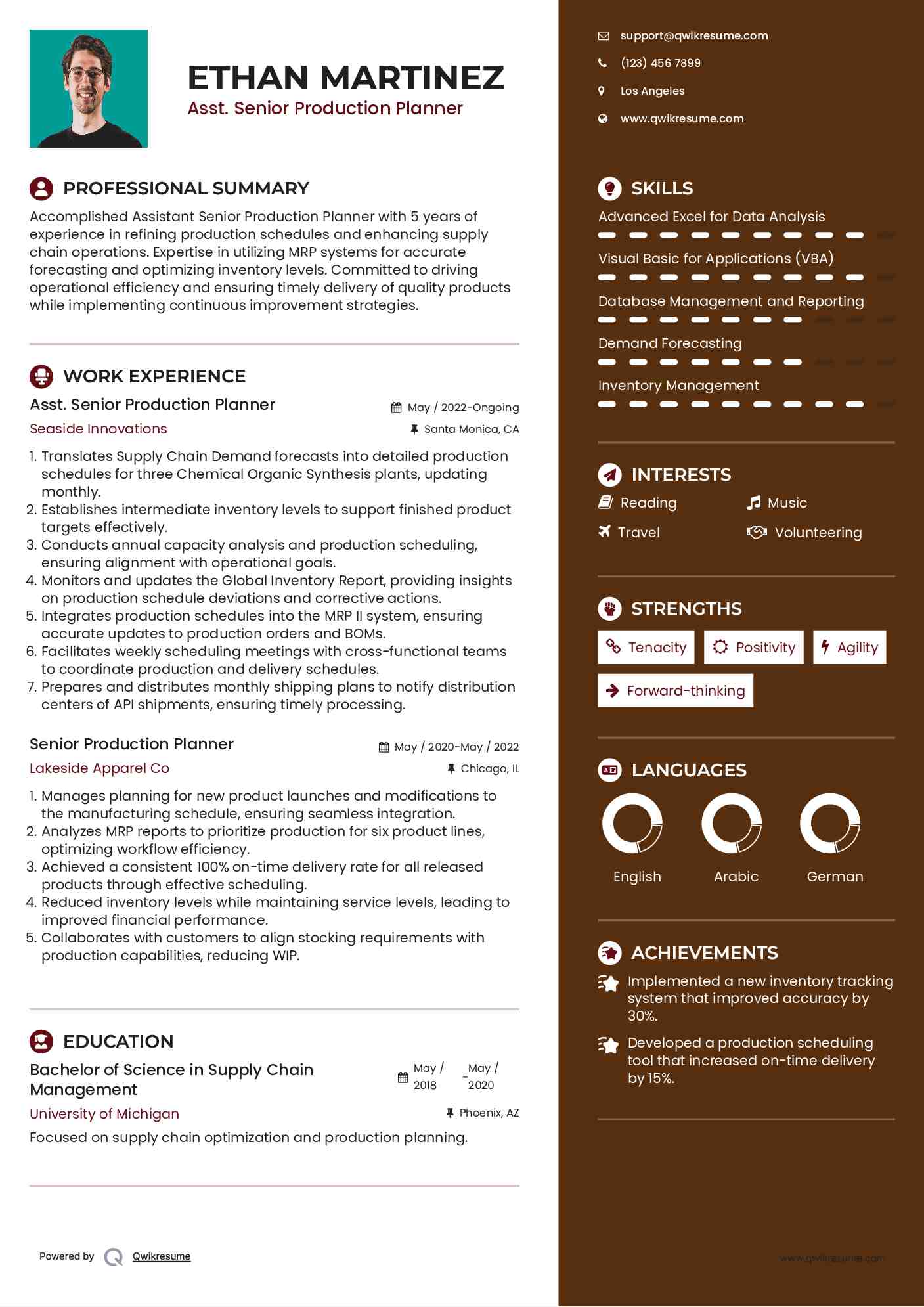

Asst. Senior Production Planner Resume

Objective : Manager with an extensive, well-rounded career in Pharmaceuticals Production Planning (15 years), Warehousing (13 years) and Medical Devices Manufacturing (3 years). Analytical, organized, details and results oriented, with a hands-on management style, constantly implementing operational changes (lean operations) to optimize process efficiency, safety, cost and compliance.

Skills : Microsoft Excel, Visual Basic, Microsoft Access, Japanese Language.

Description :

- Converts the Supply Chain "Demand" forecast into a "Production Supply Plan" analysis for three Chemical (Organic Synthesis) plants, and develop the corresponding detailed twelve month production schedule, updating analysis and schedule at least in a monthly basis.

- Develops the corresponding intermediate inventory schedule levels supporting the finished product inventory targets.

- Develops a "next year" full supply analysis and production schedule, for plant capacity projections, and update as well in a monthly basis.

- Updates in a monthly basis the Supply Chain intranet "Global Inventory Report" (Demand & Supply Analysis), and provide monthly updates on production schedule deviations & corrective plan of action.

- Loads (create) the entire Production Schedule (12 month rolling) into the company's MRP II system (MAP - AS400 system) and make corresponding weekly, monthly updates to the Production Orders, Product Structures (BOM) and Routings as required.

- Directs the weekly Scheduling Meeting with representatives from QA, QC, Engineering, ES&H, QA Labs,, Organic Synthesis Production, Purchasing, Warehousing, and Shipping, coordinating the Production, release and delivery of the drug substance (API) production to the Pharmaceutical plant for final processing into Finished product.

- Prepares, updates and distribute (at least in a in a monthly basis), the corresponding "Shipping Plan" (schedule) to notify Distribution Centers and production management on other corporate manufacturing sites, of Finished product (API) shipments to the distribution centers for further processing in countries supported by them.

- Develops Contingency Plans, Monthly Financial Production Forecast, and Annual Budget Production Volumes with the corresponding Intermediates Inventory.

Experience

2-5 Years

Level

Junior

Education

B.A

Senior Production Planner Resume

Summary : A forward thinking International Human Resources Executive that provides progressive operational, employee development and human resources support for various industries. A creative leader that provides effective advice, guidance and direction to create innovative thinking for enhanced employee development and involvement.

Skills : SAP, Excel, Planning, Procurement, Scheduling, SAP Training Co-Workers.

Description :

- Created and maintained detailed production/manufacturing build plan schedules.

- Created and effectively monitored requisitions through P.O.placement, working with Procurement ensuring timely delivery of material to support a continuous and controlled flow of material to support established production schedules and product lines.

- Created production, machine shop and optics shop work orders through MRP based off the build plan ensuring on time delivery from sub-assembly to finished product.

- Effectively monitored and reported to management production assembly activity to ensure a smooth and seamless flow to support end item deliverables exceeding production requirements.

- Responsible for monitoring and troubleshooting potential scheduling impacts to production.

- Maintained detailed reports on material shortage deficiencies, issues and concerns and prepared/presented weekly program status reports to management.

- Effectively coordinated and followed through with complex engineering changes ensuring timely and accurate implementation through procurement and operations.

Experience

10+ Years

Level

Senior

Education

Bachelor's