Production Supervisor Resume

Objective : Dynamic Production Supervisor with two years of experience in optimizing manufacturing processes and enhancing team productivity. Skilled in implementing effective training programs and quality control measures to ensure operational excellence. Committed to fostering a collaborative work environment and achieving production goals while maintaining safety standards. Eager to contribute my expertise to drive success in a fast-paced production setting.

Skills : Lean Manufacturing Principles, Production Operations Management, Manufacturing Line Oversight, Team Leadership And Development

Description :

- Managed production line operations to meet quality, cost, and safety targets.

- Developed training programs for new hires, ensuring compliance with company policies.

- Monitored performance metrics and implemented corrective actions to optimize productivity.

- Provided timely feedback to supervisors regarding production challenges and opportunities for improvement.

- Ensured all preventive maintenance protocols were followed to minimize equipment downtime.

- Conducted safety orientations and led safety meetings to promote a safe working environment.

- Collaborated with quality control to address food safety and regulatory compliance issues.

Experience

0-2 Years

Level

Entry Level

Education

B.S. in MFG Mgmt

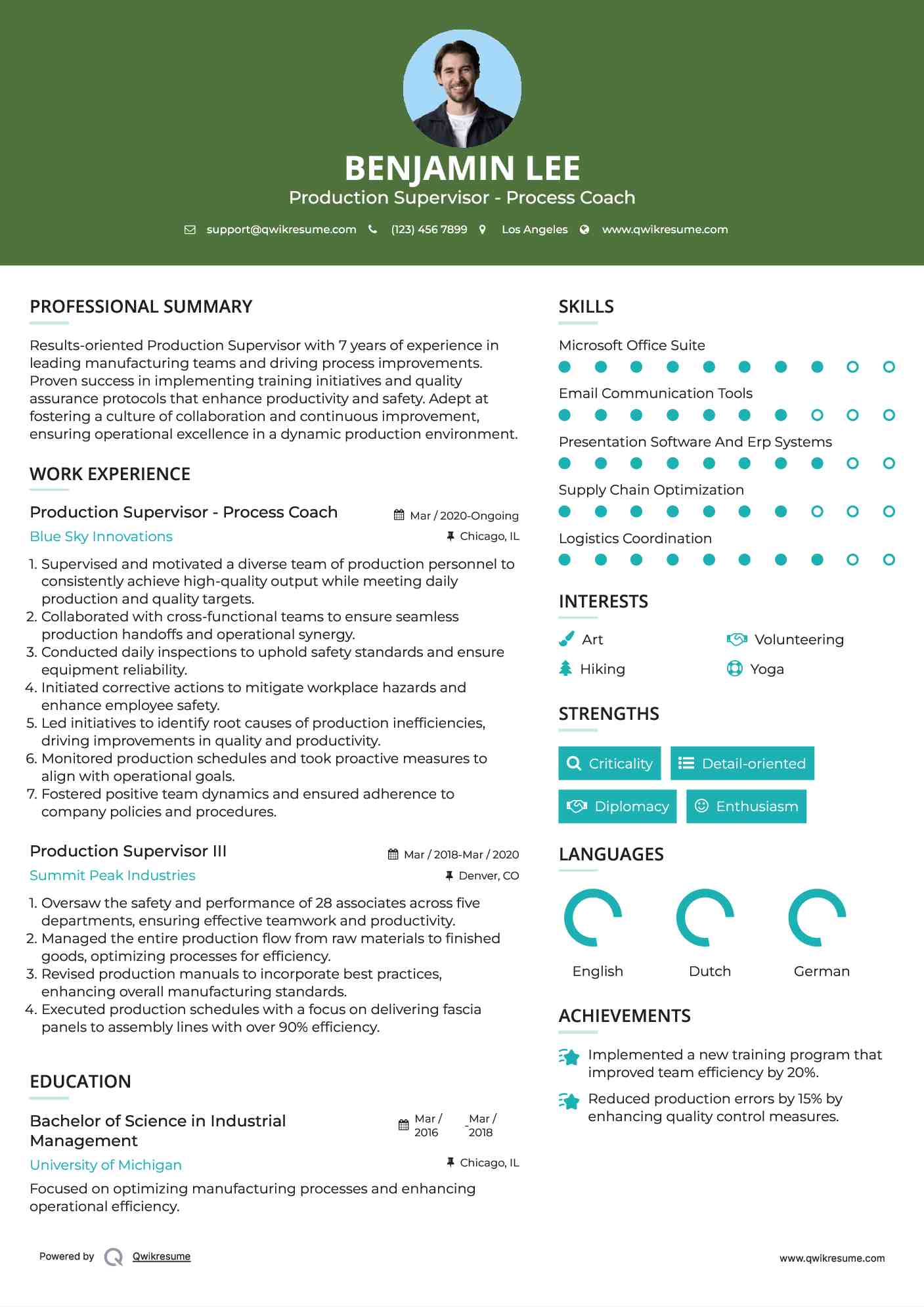

Production Supervisor - Process Coach Resume

Headline : Results-oriented Production Supervisor with 7 years of experience in leading manufacturing teams and driving process improvements. Proven success in implementing training initiatives and quality assurance protocols that enhance productivity and safety. Adept at fostering a culture of collaboration and continuous improvement, ensuring operational excellence in a dynamic production environment.

Skills : Microsoft Office Suite, Email Communication Tools, Presentation Software And Erp Systems, Supply Chain Optimization, Logistics Coordination

Description :

- Supervised and motivated a diverse team of production personnel to consistently achieve high-quality output while meeting daily production and quality targets.

- Collaborated with cross-functional teams to ensure seamless production handoffs and operational synergy.

- Conducted daily inspections to uphold safety standards and ensure equipment reliability.

- Initiated corrective actions to mitigate workplace hazards and enhance employee safety.

- Led initiatives to identify root causes of production inefficiencies, driving improvements in quality and productivity.

- Monitored production schedules and took proactive measures to align with operational goals.

- Fostered positive team dynamics and ensured adherence to company policies and procedures.

Experience

5-7 Years

Level

Management

Education

B.S. Ind. Mgmt.

Production Supervisor Resume

Objective : Accomplished Production Supervisor with 5 years of experience in optimizing production workflows and leading high-performing teams. Expertise in training and implementing quality assurance protocols to enhance operational efficiency. Passionate about fostering a culture of safety and continuous improvement, I aim to leverage my skills to drive success in a dynamic manufacturing environment.

Skills : Forklift Operation, Cross-functional Teamwork, Process Improvement, Quality Assurance, Team Leadership, Cost Reduction

Description :

- Supervised a team of 12, ensuring adherence to production schedules and quality standards.

- Implemented daily production verification processes to meet customer quality expectations.

- Ensured safety compliance while enhancing team performance through accountability measures.

- Monitored line run requirements and coordinated maintenance for optimal efficiency.

- Analyzed production data to forecast needs and improve output.

- Provided clear instructions on specifications and company procedures to enhance workforce understanding.

- Conducted comprehensive training for new employees on equipment and safety protocols.

Experience

2-5 Years

Level

Senior

Education

B.S. in Man. Mgmt.

Senior Production Supervisor Resume

Headline : Proficient Senior Production Supervisor with 7 years of experience in optimizing manufacturing operations and enhancing team performance. Expertise in implementing process improvements and quality control measures to achieve production targets. Passionate about developing a safety-focused, collaborative work culture that drives operational excellence and meets customer demands.

Skills : Production Planning, Manufacturing Systems, Erp Software Proficiency, Team Motivation, Safety Management, Forecasting

Description :

- Oversaw daily operations of hydraulic rod lines, ensuring optimal production efficiency.

- Facilitated tier 1 and tier 2 meetings to communicate daily schedules, safety protocols, and productivity metrics.

- Supervised team members to uphold safety standards while meeting quality and productivity goals.

- Led continuous safety improvement initiatives, addressing incidents through corrective actions and recognition programs.

- Managed machine scheduling and labor allocation to maximize performance and meet delivery timelines.

- Generated production flow reports to monitor and enhance operational efficiency.

- Provided daily feedback on job performance, fostering a culture of accountability and improvement.

Experience

5-7 Years

Level

Senior

Education

B.S. in Mfg. Eng.

Production Supervisor Resume

Objective : Highly motivated Production Supervisor with 5 years of experience in enhancing manufacturing efficiency and team performance. Proficient in implementing quality control measures and training programs, ensuring compliance with safety standards. Eager to leverage my expertise to optimize production processes and foster a collaborative work environment that drives organizational success.

Skills : Mechanical Troubleshooting, Forklift Safety Operations, Conflict Resolution, Performance Metrics, Equipment Maintenance, Regulatory Compliance

Description :

- Supervising approximately 80 employees across various production areas, ensuring optimal workflow and productivity.

- Coordinating manufacturing and quality assurance activities to achieve production goals while adhering to cost and quality standards.

- Establishing resource requirements for materials, equipment, and manpower to enhance production efficiency.

- Collaborating with functional groups such as planning and distribution to align production schedules.

- Developing personnel to ensure the efficient operation of production functions and foster team growth.

- Implementing and overseeing safety programs to maintain a clean and secure workplace for all employees.

- Conducting periodic evaluations of process specifications to identify inefficiencies and implement improvements.

Experience

2-5 Years

Level

Junior

Education

B.S. in Mfg. Mgmt.

Production Supervisor II Resume

Summary : With a decade of experience as a Production Supervisor, I excel in enhancing operational efficiency and leading diverse teams. My expertise includes implementing robust training programs and quality improvement initiatives, driving production goals while prioritizing safety. I am dedicated to fostering a proactive work environment that embraces continuous improvement and innovation in manufacturing processes.

Skills : Training Program Design & Implementation, Manufacturing Processes, Production Reporting & Compliance, Operational Equipment Oversight

Description :

- Oversaw the daily operations of a 50-member production team, ensuring alignment with production goals and quality standards.

- Managed employee timecards and coordinated payroll processes in collaboration with HR.

- Developed and executed training programs for new employees on custom cable assembly, enhancing team capabilities.

- Implemented hazardous waste disposal programs, ensuring compliance with environmental regulations.

- Led Kanban development initiatives, resulting in a significant reduction in inventory costs.

- Maintained high performance standards by conducting regular quality checks and process evaluations.

- Coordinated workload assignments and managed capacity for staff scheduling, optimizing resource utilization.

Experience

7-10 Years

Level

Management

Education

B.S. in Manuf. Mgmt.

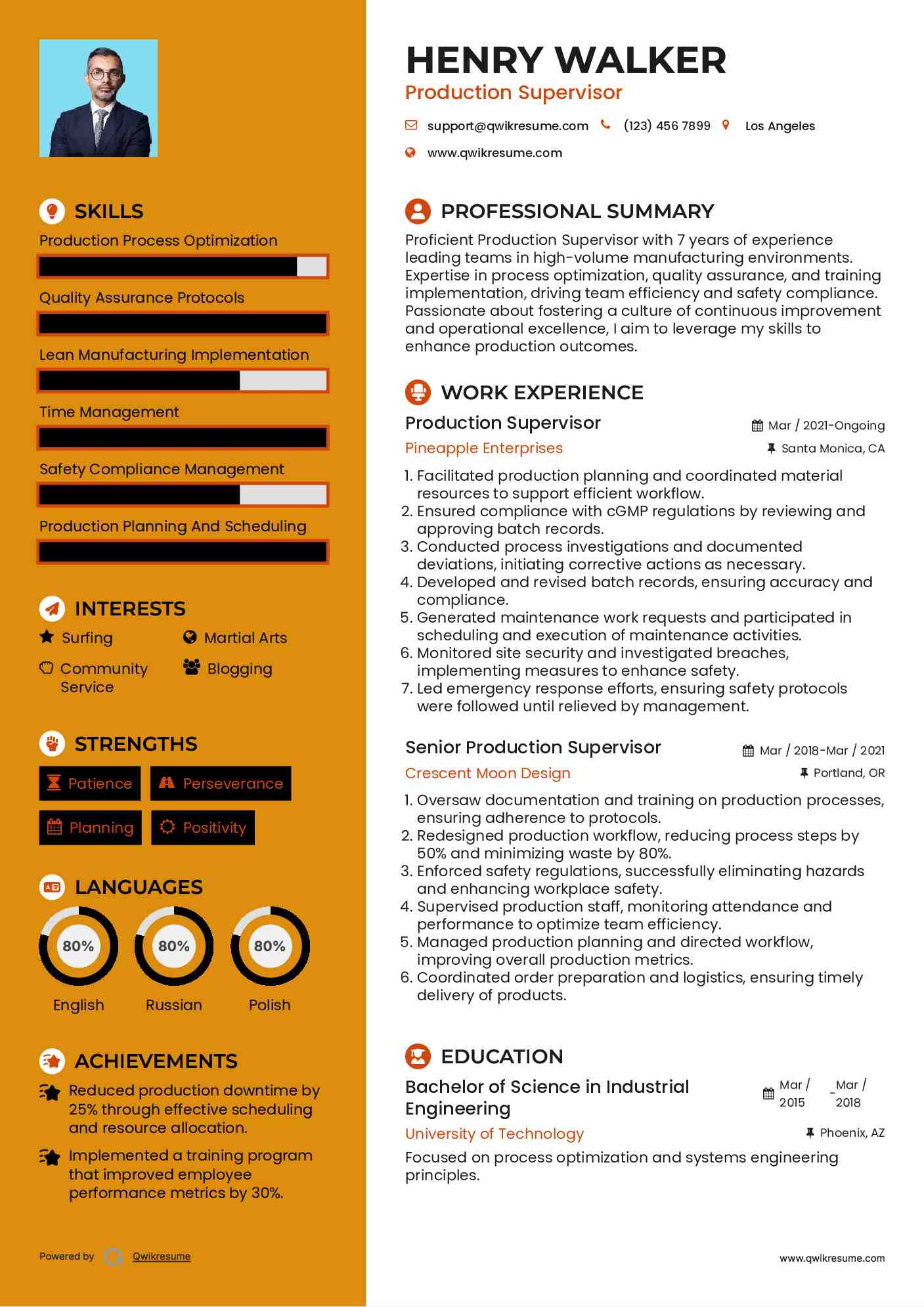

Production Supervisor Resume

Headline : Proficient Production Supervisor with 7 years of experience leading teams in high-volume manufacturing environments. Expertise in process optimization, quality assurance, and training implementation, driving team efficiency and safety compliance. Passionate about fostering a culture of continuous improvement and operational excellence, I aim to leverage my skills to enhance production outcomes.

Skills : Production Process Optimization, Quality Assurance Protocols, Lean Manufacturing Implementation, Time Management, Safety Compliance Management, Production Planning And Scheduling

Description :

- Facilitated production planning and coordinated material resources to support efficient workflow.

- Ensured compliance with cGMP regulations by reviewing and approving batch records.

- Conducted process investigations and documented deviations, initiating corrective actions as necessary.

- Developed and revised batch records, ensuring accuracy and compliance.

- Generated maintenance work requests and participated in scheduling and execution of maintenance activities.

- Monitored site security and investigated breaches, implementing measures to enhance safety.

- Led emergency response efforts, ensuring safety protocols were followed until relieved by management.

Experience

5-7 Years

Level

Management

Education

B.S. IE

Production Supervisor - Plant Resume

Headline : Accomplished Production Supervisor with 7 years of experience driving operational efficiency in high-volume manufacturing settings. Demonstrated expertise in optimizing production workflows, implementing quality assurance protocols, and fostering team collaboration. Dedicated to achieving production goals while maintaining safety standards and enhancing employee performance.

Skills : Bilingual Communication Skills, Advanced Problem-solving Skills, Strong Interpersonal Communication, Payroll And Attendance Management, Proficient In Microsoft Office Suite, Sap Production Planning And Control

Description :

- Oversaw production lines, ensuring adherence to lean manufacturing principles and safety standards.

- Collaborated with cross-functional teams to maintain optimal production flow and resolve operational issues.

- Implemented quality assurance measures, ensuring compliance with product specifications and government regulations.

- Coordinated with HR to manage staffing needs and conduct performance evaluations.

- Engaged with customers and vendors to address inquiries and resolve production-related challenges.

- Processed incoming purchase orders, ensuring alignment with established operational procedures.

- Facilitated continuous improvement initiatives, enhancing operational efficiency and team performance.

Experience

5-7 Years

Level

Senior

Education

B.S. in IT

Production Supervisor Resume

Summary : With a decade of extensive experience in production supervision, I excel in driving operational efficiency and enhancing team performance in manufacturing environments. My expertise encompasses implementing strategic quality control measures and training programs, ensuring compliance with safety regulations. I am committed to fostering a culture of continuous improvement while achieving production targets and optimizing processes.

Skills : Team Building, Operational Strategy, Motivational Skills, Supplier Coordination, Cross-functional Collaboration, Change Management

Description :

- Managed a medical manufacturing team of 15-20 employees, ensuring adherence to policies and production quotas while providing expert guidance.

- Resolved personnel issues by analyzing data and recommending effective solutions, contributing to a harmonious work environment.

- Communicated job expectations and assessed production volume, enhancing team accountability and performance.

- Ensured department met production plans and shipping deadlines in a fast-paced manufacturing setting.

- Provided training on Epicor production and Kronos workforce software, improving overall team productivity.

- Increased department output by 13-15% annually through clear communication and performance assessments.

- Supervised daily implementation of SOPs and prerequisite programs, ensuring accurate documentation and compliance.

Experience

7-10 Years

Level

Management

Education

B.S. in Manuf. Mgmt.

Production Supervisor Resume

Objective : Results-driven Production Supervisor with two years of hands-on experience in enhancing production efficiency and fostering a culture of teamwork. Proficient in implementing training protocols and quality assurance measures, ensuring adherence to safety standards. Committed to driving operational excellence and meeting production targets in a dynamic manufacturing environment.

Skills : Problem Solving, Communication Skills, Cross-functional Team Collaboration, Effective Communication Skills, Report Writing And Documentation

Description :

- Oversee production lines to ensure compliance with safety, quality, and productivity standards.

- Optimize labor allocation and line density to meet financial objectives.

- Communicate daily production goals to customers and ensure timely delivery.

- Maintain accurate production reports for management review.

- Collaborate with team members to troubleshoot and resolve operational issues.

- Conduct training and performance evaluations for 16-32 direct reports.

- Update visual production tracking boards and facilitate daily team reviews.

Experience

0-2 Years

Level

Entry Level

Education

B.S. in Mfg.

Manufacturing Production Supervisor II Resume

Objective : Results-oriented Manufacturing Production Supervisor with two years of experience in streamlining production processes and enhancing team performance. Proficient in implementing training initiatives and quality assurance practices to achieve operational excellence. Dedicated to promoting a safe and collaborative work environment, I am eager to apply my skills to drive efficiency and meet production objectives.

Skills : Project Management, Root Cause Analysis, Production Reporting, Customer Focus, Technical Skills

Description :

- Oversaw daily operations across multiple departments to ensure efficient workflow.

- Implemented training programs that enhanced employee skills and productivity.

- Streamlined processes to reduce downtime and improve production efficiency.

- Introduced quality control measures that increased product quality and reduced defects.

- Fostered a team-oriented environment that focused on safety and collaboration.

- Conducted regular performance reviews to identify areas for improvement.

- Developed and maintained production schedules to meet customer demand.

Experience

0-2 Years

Level

Entry Level

Education

BSMM

Assistant Manufacturing Production Supervisor I Resume

Objective : Results-driven professional with 5 years of experience in manufacturing supervision, specializing in optimizing production workflows and enhancing team performance. Skilled in implementing training programs and quality assurance measures to ensure operational efficiency and safety compliance. My goal is to leverage my expertise to foster a productive work environment and achieve organizational success.

Skills : Process Optimization, Training And Development, Decision Making, Adaptability, Attention To Detail, Strategic Planning

Description :

- Supervised and coordinated activities of 60-75 employees on a high-speed assembly line to ensure optimal productivity.

- Scheduled daily production activities, ensuring alignment with operational goals.

- Conducted comprehensive employee training in safety protocols and quality standards.

- Initiated job rotation to enhance employee skill sets and adaptability.

- Demonstrated flexibility and attention to detail while multitasking in a fast-paced environment.

- Presented performance reports and operational updates to management.

- Managed equipment preventive maintenance and troubleshooting to minimize downtime.

Experience

2-5 Years

Level

Junior

Education

B.S. in Mfg. Eng.

Manufacturing Production Supervisor Resume

Objective : Results-driven Production Supervisor with over 5 years of experience in optimizing manufacturing processes and leading teams to achieve production goals. Proven track record in implementing lean manufacturing principles, reducing waste, and improving efficiency. Strong leadership skills with a focus on safety, quality, and continuous improvement. Adept at training staff and fostering a collaborative work environment.

Skills : Lean Manufacturing Certified, Employee Engagement, Operational Efficiency, Risk Management, Workplace Organization, Process Documentation

Description :

- Completed Value Stream Mapping (VSM) activities on three production lines, resulting in reduced manpower and increased efficiency.

- Established lean process improvements, identifying technological applications to enhance safety and efficiency.

- Chosen to create a production plan for launching a new product line, collaborating with senior management.

- Developed a detailed bill of materials and floor plan layout tailored to product specifications.

- Monitored production processes, implementing changes to optimize efficiency, safety, and output.

- Motivated team members to achieve production goals through effective communication and leadership.

- Trained production staff to identify issues and implement solutions while maintaining safety standards.

Experience

0-2 Years

Level

Entry Level

Education

B.S. in Mfg. Mgmt.

Senior Production Supervisor/Analyst Resume

Headline : Accomplished Senior Production Supervisor with 7 years in manufacturing, driving process optimization and team leadership. Expert in implementing training and quality assurance protocols that elevate productivity and safety standards. Committed to fostering a culture of continuous improvement and operational excellence, I am eager to enhance production outcomes in a dynamic environment.

Skills : Forklift Operation Certified, Inventory Optimization, Data Analysis, Resource Allocation, Quality Control, Budget Management

Description :

- Oversaw production of medical devices, ensuring compliance with FDA and cGMP standards while utilizing LEAN principles.

- Trained operators on DOPs, SOPs, and MPIs, enhancing workforce competency.

- Conducted daily production meetings to address issues and coordinate with upper management.

- Certified 30 operators on R&D projects, transitioning them to full production in under a year.

- Collaborated with cross-functional teams to implement process improvements.

- Utilized SAP for effective production scheduling and resource allocation.

- Monitored and reported on production metrics to drive continuous improvement.

Experience

5-7 Years

Level

Senior

Education

BSME

Senior Production Supervisor/Consultant Resume

Headline : Strategic Senior Production Supervisor with 7 years of experience elevating manufacturing performance through effective team leadership and process optimization. Skilled in implementing quality control and training programs that drive efficiency and safety. Committed to fostering an innovative work culture that continuously improves operational standards and meets production targets.

Skills : Production Scheduling, Supply Chain Coordination, Workplace Safety, Documentation Skills

Description :

- Reported directly to the Superintendent, overseeing the daily operations of front and rear seat manufacturing lines.

- Supervised a team of 40 union production workers, ensuring adherence to quality standards and operational goals.

- Conducted product inspections to guarantee compliance with Chrysler's quality requirements.

- Provided actionable feedback and recommendations for continuous improvement, enhancing overall efficiency.

- Projected man hours for union workers, managing labor costs effectively.

- Participated in the grievance process and enforced disciplinary actions as necessary.

- Trained employees across various processes, ensuring a versatile and skilled workforce.

Experience

5-7 Years

Level

Senior

Education

B.S. in ME

Senior Production Supervisor Resume

Headline : Dedicated Production Supervisor with a solid background in overseeing daily operations in fast-paced manufacturing environments. Skilled in workforce management, process improvement, and quality assurance. Committed to fostering a culture of safety and continuous improvement while meeting production targets. Excellent communicator with a focus on team collaboration and problem-solving.

Skills : Workflow Optimization, Staff Scheduling, Risk Assessment, Analytical Thinking, Technical Troubleshooting, Workforce Management

Description :

- Reviewed processing schedules and production orders to optimize inventory and staffing, ensuring budget compliance and timely delivery.

- Directed production and distribution activities, enhancing operational efficiency across multiple departments.

- Developed robust production tracking systems, analyzing operational reports to identify and resolve production issues.

- Collaborated with technical teams to enhance production processes and troubleshoot operational challenges.

- Managed hiring, training, and evaluation of staff, effectively resolving personnel grievances and fostering team cohesion.

- Implemented and enforced safety and sanitation regulations, ensuring a secure working environment.

- Coordinated employee activities in production, ensuring adherence to quality standards and operational goals.

Experience

5-7 Years

Level

Senior

Education

B.S. in Mfg. Mgmt.

Jr. Assistant Production Supervisor Resume

Headline : Results-oriented professional with 7 years of experience in production supervision, focusing on enhancing operational efficiency and team performance. Proficient in implementing quality control measures and training programs that meet safety standards. Committed to fostering a collaborative environment while achieving production goals and driving continuous improvement in manufacturing processes.

Skills : Safety Compliance, Scheduling, Staff Supervision, Production Workflow, Goal Setting, Supplier Relations

Description :

- Delivered comprehensive training on production protocols, safety measures, and quality standards to new hires, documented in the TRAQ matrix.

- Utilized Excel and SAP to accurately enter daily production data and monitor KPIs.

- Reported equipment malfunctions, quality issues, and downtime to management to facilitate prompt resolutions.

- Maintained production flow by managing inventory levels and placing orders for necessary materials.

- Completed leadership, time management, and SAP training to enhance operational skills.

- Developed a high-performing team by mentoring staff to meet departmental expectations.

- Ensured all production machines were adequately supplied with raw materials for seamless operations.

Experience

5-7 Years

Level

Senior

Education

B.S. in Manuf. Mgmt.

Assistant Production Supervisor II Resume

Objective : Results-focused Assistant Production Supervisor with two years of experience in streamlining manufacturing processes and enhancing team performance. Adept at training employees and implementing quality assurance protocols to ensure operational excellence. Passionate about fostering a safe and efficient work environment while driving productivity and meeting production targets.

Skills : Typing Proficiency Certification, Inventory Control And Management, Continuous Improvement, Material Handling, Workforce Training, Data-driven Decision Making

Description :

- Supervised a team of 10-15 personnel in the production of automotive parts, ensuring adherence to quality and safety standards.

- Conducted regular performance evaluations and provided constructive feedback to enhance team skills and productivity.

- Implemented continuous improvement strategies that resulted in a 12% increase in overall production output.

- Performed routine maintenance on automated assembly lines to minimize downtime.

- Oversaw quality checks using precision tools to ensure compliance with production specifications.

- Developed and managed employee schedules to optimize workforce efficiency.

- Trained new hires on safety protocols and operational procedures to maintain a secure work environment.

Experience

0-2 Years

Level

Entry Level

Education

AAS in Manufacturing Tech

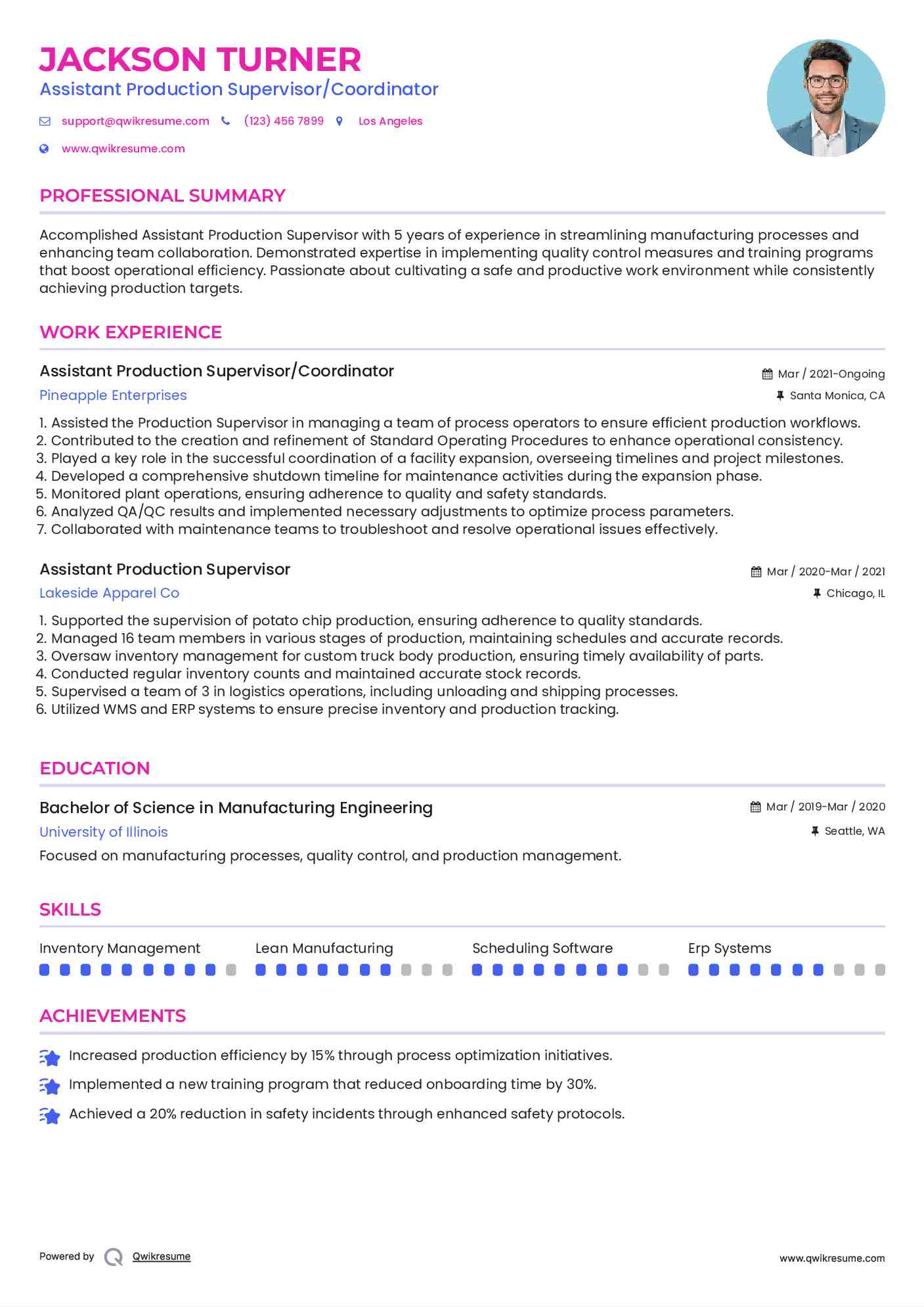

Assistant Production Supervisor/Coordinator Resume

Objective : Accomplished Assistant Production Supervisor with 5 years of experience in streamlining manufacturing processes and enhancing team collaboration. Demonstrated expertise in implementing quality control measures and training programs that boost operational efficiency. Passionate about cultivating a safe and productive work environment while consistently achieving production targets.

Skills : Inventory Management, Lean Manufacturing, Scheduling Software, Erp Systems

Description :

- Assisted the Production Supervisor in managing a team of process operators to ensure efficient production workflows.

- Contributed to the creation and refinement of Standard Operating Procedures to enhance operational consistency.

- Played a key role in the successful coordination of a facility expansion, overseeing timelines and project milestones.

- Developed a comprehensive shutdown timeline for maintenance activities during the expansion phase.

- Monitored plant operations, ensuring adherence to quality and safety standards.

- Analyzed QA/QC results and implemented necessary adjustments to optimize process parameters.

- Collaborated with maintenance teams to troubleshoot and resolve operational issues effectively.

Experience

2-5 Years

Level

Junior

Education

B.S. in Mfg Eng.

Assistant Production Supervisor Resume

Objective : Proactive Assistant Production Supervisor with two years of hands-on experience in optimizing production workflows and enhancing team collaboration. Proficient in implementing quality assurance measures and training programs that elevate operational standards. Passionate about creating a safe and efficient work environment, I am eager to contribute my skills to achieve production excellence.

Skills : Compliance Knowledge, Standard Operating Procedures, Supplier Management, Technical Documentation, Process Standardization

Description :

- Led a team of operators to achieve production targets and maintain quality standards.

- Maintained high-performance standards, focusing on schedules, deadlines, and quality assurance.

- Coordinated Sensor department activities with Engineering and Sales to ensure seamless operations.

- Implemented quality programs that reduced costs and increased customer satisfaction.

- Created effective schedules to meet production deadlines efficiently.

- Oversaw production, assembly, and calibration of over 200 sensor types.

- Managed order picking and shipping processes to enhance customer service.

Experience

0-2 Years

Level

Entry Level

Education

A.S. Manufacturing Tech