Quality Control Technician Resume

Objective : Driven Quality Control Technician with 2 years of experience in manufacturing and inspection processes. Adept at ensuring product compliance through meticulous testing and quality assurance protocols. Committed to fostering a culture of safety and efficiency while collaborating effectively with cross-functional teams to meet production goals.

Skills : Quality Inspection Skills, Data Analysis And Reporting, Attention To Detail, Data Analysis

Description :

- Conducted thorough quality inspections in industrial refrigeration, ensuring compliance with customer specifications.

- Acted as the primary QA liaison between clients and suppliers on high-stakes liquefied natural gas projects.

- Strengthened relationships with engineering and shop floor personnel to streamline processes and enhance team collaboration.

- Developed training materials and work instructions to facilitate onboarding for new hires.

- Coordinated with production leads to ensure ISO 9001 compliance and adherence to ASME standards.

- Reviewed engineering drawings for accuracy and compliance prior to production release.

- Certified materials to meet specialized customer and engineering requirements, ensuring adherence to ASME guidelines.

Experience

0-2 Years

Level

Entry Level

Education

AAS QC

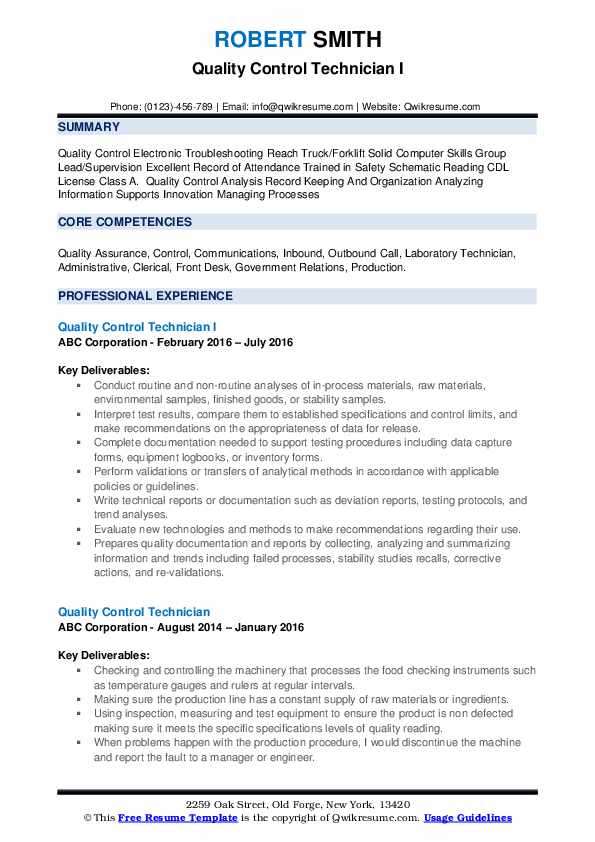

Junior Quality Control Technician Resume

Objective : Enthusiastic Junior Quality Control Technician with 2 years of hands-on experience in quality assurance and testing processes. Proficient in assessing product quality against specifications and implementing corrective actions. Eager to contribute to a safety-focused environment while collaborating with team members to enhance production efficiency and maintain high-quality standards.

Skills : Effective Communication, Quality Assurance Testing, Quality Auditing, Quality Control Procedures, Documentation Management

Description :

- Analyze test results, comparing them to specifications and control limits, providing recommendations for data release.

- Validate analytical methods following established guidelines to ensure compliance.

- Prepare technical documentation, including deviation reports and testing protocols.

- Assess new technologies and methods, offering insights for potential implementation.

- Compile quality reports by analyzing trends and documenting corrective actions.

- Enhance departmental reputation by proactively addressing new challenges and opportunities.

- Collaborate with production teams to ensure adherence to quality standards.

Experience

0-2 Years

Level

Junior

Education

AS in QC

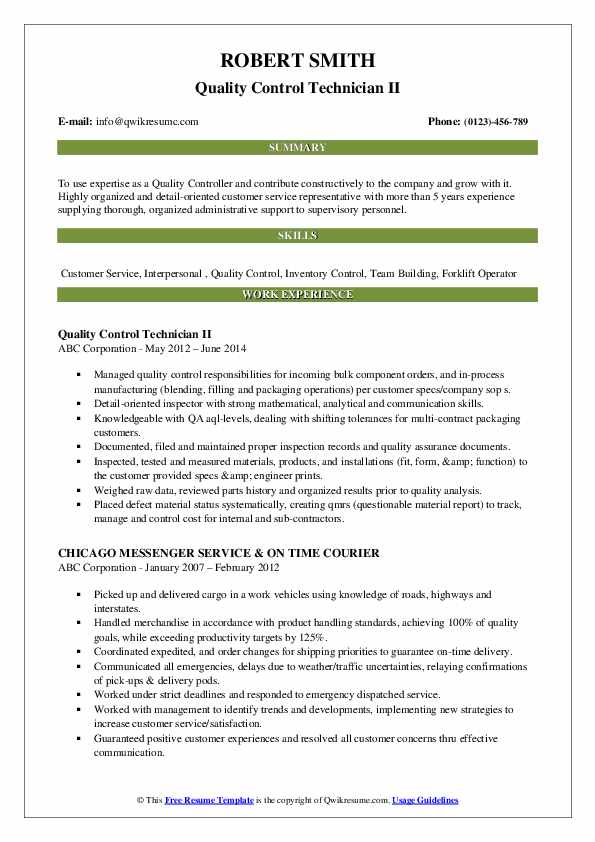

Quality Control Technician Resume

Objective : Quality Control Technician with 2 years of experience in product inspection and quality assurance. Skilled in executing comprehensive testing protocols and ensuring adherence to industry standards. Passionate about driving continuous improvement in processes and fostering teamwork to enhance operational efficiency and product quality.

Skills : Quality Assurance, Communication Skills, Project Management, Quality Control Tools, Statistical Process Control, Visual Inspection

Description :

- Oversaw quality control for incoming bulk components and in-process manufacturing, ensuring compliance with customer specifications and company SOPs.

- Conducted detailed inspections using strong analytical and mathematical skills to maintain high-quality standards.

- Applied knowledge of QA AQL levels to manage varying tolerances for multi-contract packaging customers.

- Inspected and tested materials and products to ensure fit, form, and function met engineering specifications.

- Analyzed raw data and organized results to facilitate comprehensive quality assessments.

- Managed defect material status systematically, creating Questionable Material Reports (QMR) to track and control costs.

- Administered the receipt and retention of packaging components test documentation to ensure compliance.

Experience

0-2 Years

Level

Entry Level

Education

AAS QA

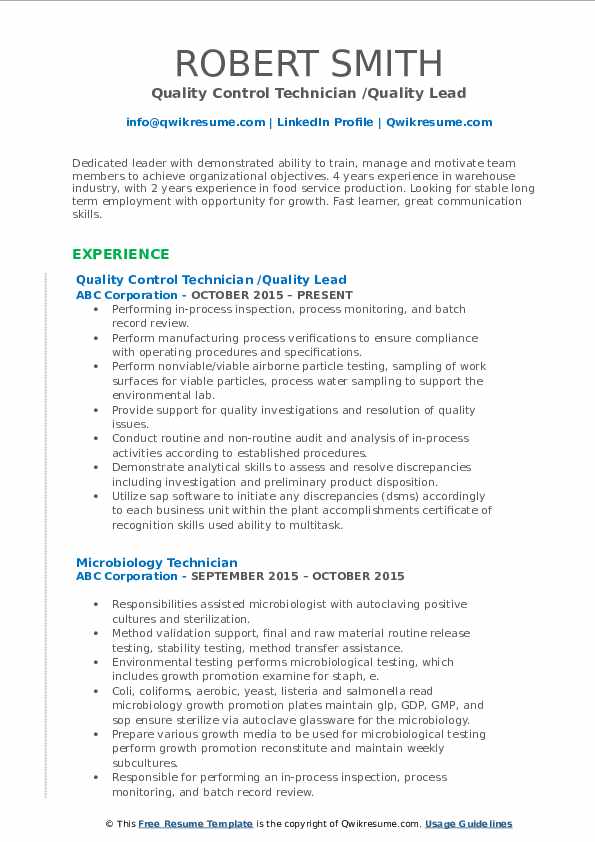

Lead Quality Control Technician Resume

Headline : Accomplished Lead Quality Control Technician with 7 years of experience in quality assurance and compliance within manufacturing environments. Proven expertise in implementing rigorous testing protocols and enhancing operational efficiency. Passionate about cultivating a culture of quality and safety while leading teams to achieve excellence in production standards.

Skills : Microsoft Office Suite, Standard Operating Procedures, Current Good Manufacturing Practices, Research And Data Analysis, First Aid And Cpr Certified, Training And Mentorship

Description :

- Conduct in-process inspections and batch record reviews to ensure compliance with quality standards.

- Verify manufacturing processes against established specifications to maintain product integrity.

- Perform environmental testing and monitoring to support compliance with safety regulations.

- Lead investigations into quality issues, developing corrective actions and preventive measures.

- Execute routine audits of in-process activities to identify areas for improvement.

- Utilize SAP software to track discrepancies and manage quality documentation efficiently.

- Analyze production data to implement preventive actions, ensuring high safety and quality standards.

Experience

5-7 Years

Level

Management

Education

B.S. QA

Quality Control Technician Resume

Headline : Quality Control Technician with 7 years of extensive experience in implementing quality assurance protocols and conducting thorough inspections. Expert in enhancing product integrity through precise testing and compliance checks. Dedicated to continuous improvement and fostering a safety-first culture within teams to achieve operational excellence.

Skills : Leadership And Team Collaboration, Effective Time Management, Computer Proficiency In Quality Control Software, Strategic Quality Control Planning, Strong Communication Skills, Motivational Skills For Team Engagement

Description :

- Executed quality control tests on production samples using advanced chromatography techniques to ensure compliance with industry standards.

- Established and enforced quality control protocols to meet stringent food safety regulations.

- Conducted bi-hourly sample collections, evaluating ingredient quality through moisture, salt, and impurity testing.

- Performed comprehensive qualitative and quantitative analyses to assess food product properties.

- Integrated quality control processes with production workflows to exceed company objectives and client expectations.

- Ensured adherence to quality standards based on client SOPs and in-house regulations.

- Completed final product inspections to confirm compliance with quality and labeling standards.

Experience

5-7 Years

Level

Senior

Education

B.S. Food Science

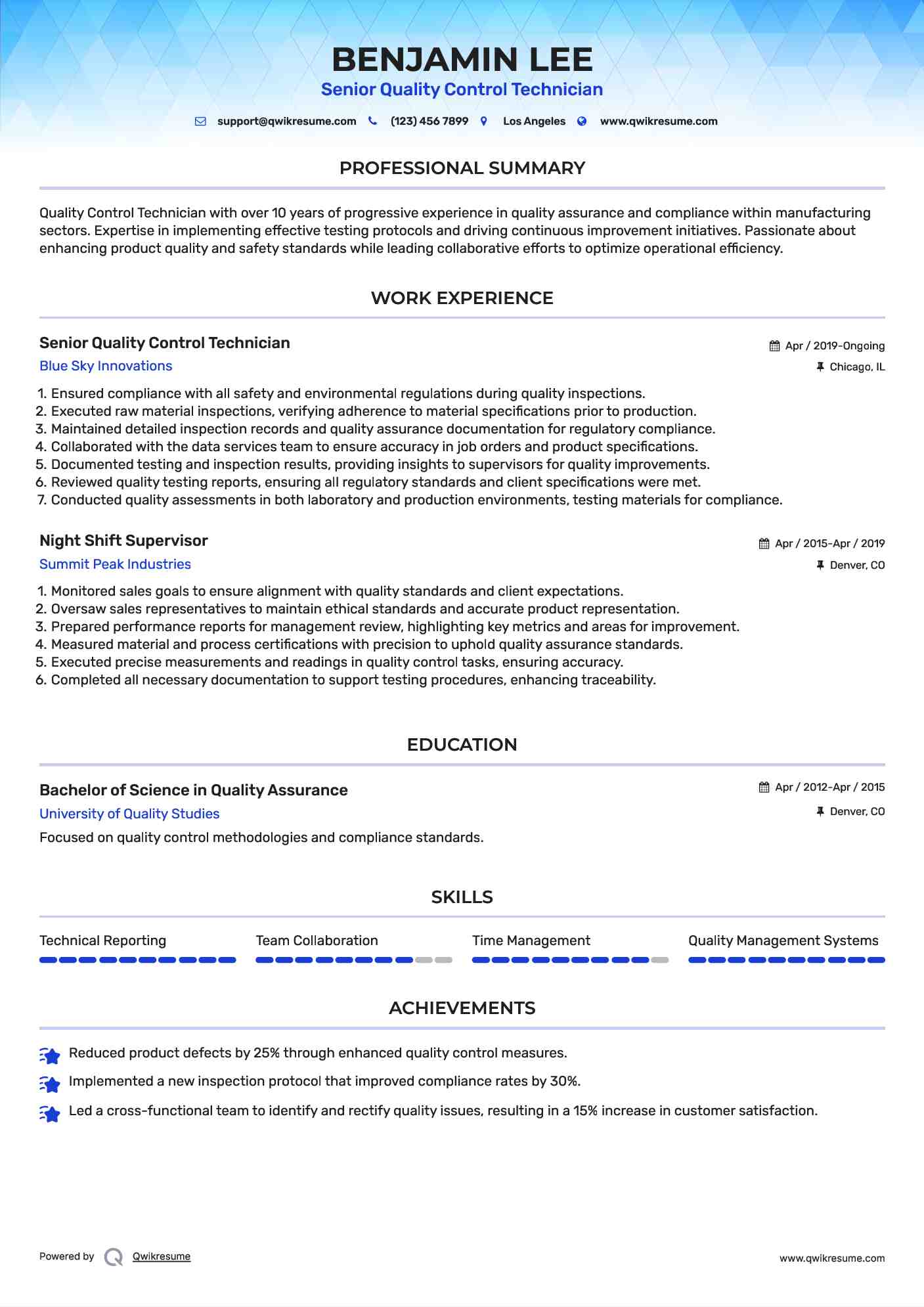

Senior Quality Control Technician Resume

Summary : Quality Control Technician with over 10 years of progressive experience in quality assurance and compliance within manufacturing sectors. Expertise in implementing effective testing protocols and driving continuous improvement initiatives. Passionate about enhancing product quality and safety standards while leading collaborative efforts to optimize operational efficiency.

Skills : Technical Reporting, Team Collaboration, Time Management, Quality Management Systems

Description :

- Ensured compliance with all safety and environmental regulations during quality inspections.

- Executed raw material inspections, verifying adherence to material specifications prior to production.

- Maintained detailed inspection records and quality assurance documentation for regulatory compliance.

- Collaborated with the data services team to ensure accuracy in job orders and product specifications.

- Documented testing and inspection results, providing insights to supervisors for quality improvements.

- Reviewed quality testing reports, ensuring all regulatory standards and client specifications were met.

- Conducted quality assessments in both laboratory and production environments, testing materials for compliance.

Experience

7-10 Years

Level

Management

Education

B.S. QA

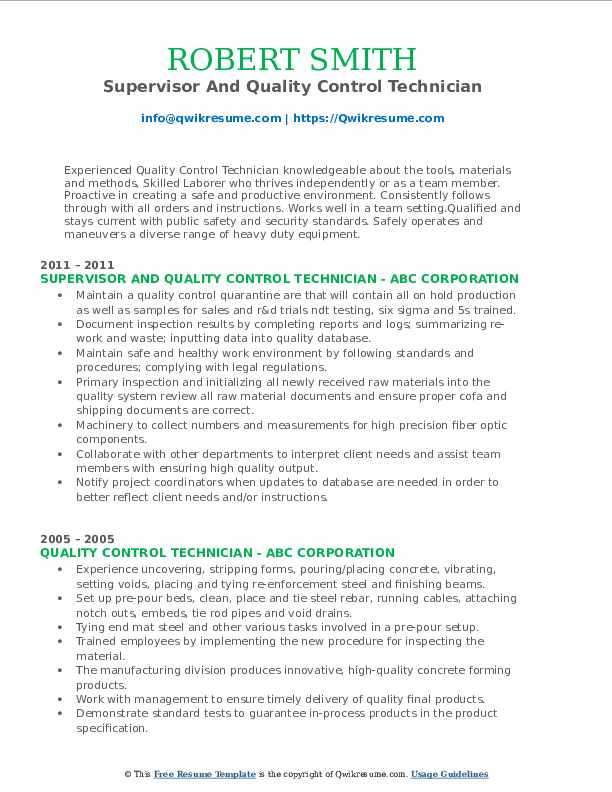

Quality Control Technician Resume

Headline : Detail-oriented Quality Control Technician with over 5 years of experience in manufacturing environments. Proficient in conducting inspections, performing tests, and analyzing data to ensure product quality and compliance with industry standards. Strong problem-solving skills and a commitment to continuous improvement, ensuring optimal production processes and customer satisfaction.

Skills : Continuous Improvement, Quality Metrics, Non-conformance Reporting, Training And Development, Software Proficiency, Risk Assessment

Description :

- Oversaw quality control quarantine area for on-hold production, ensuring proper testing and compliance.

- Documented inspection results through detailed reports, summarizing rework and waste while inputting data into the quality database.

- Maintained a safe work environment by adhering to industry standards and legal regulations.

- Performed primary inspections of newly received raw materials, verifying documents for accuracy.

- Executed high-precision measurements for fiber optic components, ensuring product integrity.

- Collaborated with cross-departmental teams to align client needs with production outputs.

- Updated project coordinators on database modifications to reflect client specifications accurately.

Experience

5-7 Years

Level

Management

Education

B.S. QA

QA/QC Technician

Resume

Headline : Quality Assurance Technician with 7 years of experience in manufacturing quality control and compliance. Demonstrated ability to implement rigorous testing protocols and enhance product integrity through precise inspections. Committed to continuous process improvement and fostering a culture of safety, ensuring all products meet stringent quality standards.

Skills : Analytical Problem Solving, Inspection Techniques, Effective Communication Skills, Collaborative Teamwork, Strong Interpersonal Skills, Organizational Skills

Description :

- Conduct comprehensive laboratory tests to assess the chemical and physical properties of raw and finished products, ensuring compliance with specifications.

- Document test results meticulously and prepare detailed reports on procedures and findings.

- Ensure product safety and compliance with local, state, and federal regulations through rigorous quality checks.

- Adhere to company and regulatory policies related to food safety and quality management.

- Manage and record test data and incidents, ensuring transparency and accountability in product quality.

- Utilize advanced laboratory techniques to evaluate product integrity throughout the manufacturing process.

- Monitor testing procedures to guarantee adherence to established specifications and protocols.

Experience

5-7 Years

Level

Management

Education

B.S. Food Science

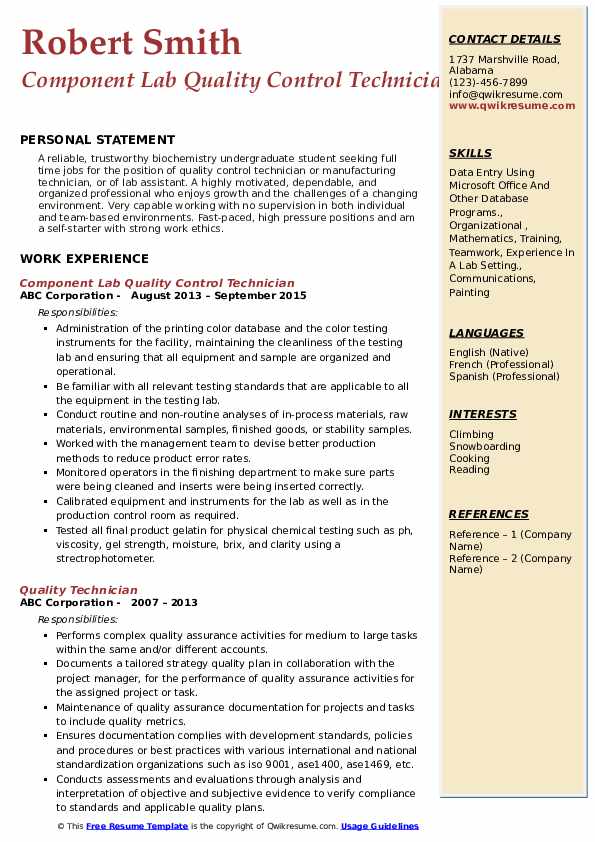

Quality Control Technician Resume

Objective : Quality Control Technician with 2 years of experience specializing in rigorous testing and compliance within manufacturing settings. Demonstrated ability to uphold quality standards through precise inspections and data analysis. Eager to leverage strong problem-solving skills to enhance production processes and contribute to a culture of safety and excellence.

Skills : Safety Standards, Quality Assurance Methodologies, Equipment Maintenance, Collaboration And Communication, Laboratory Testing And Equipment Calibration, Effective Documentation And Reporting

Description :

- Managed the color testing database and ensured cleanliness and organization of the testing lab.

- Familiarized with applicable testing standards for all laboratory equipment.

- Collaborated with management to improve production methods, reducing error rates.

- Monitored finishing department operators to verify correct cleaning and assembly processes.

- Calibrated lab equipment and production instruments as needed.

- Executed chemical and physical testing on final products, ensuring compliance with specifications.

- Documented testing results and maintained accurate records for quality assurance purposes.

Experience

0-2 Years

Level

Entry Level

Education

A.S. in QCT

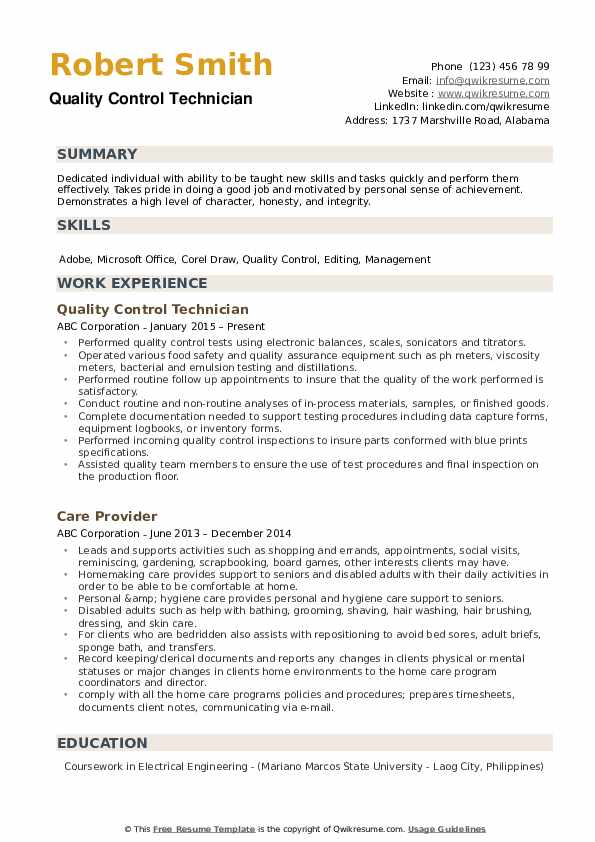

Quality Control Technician Resume

Objective : Quality Control Technician with 2 years of experience in quality assurance and product inspection. Expert in conducting comprehensive tests and ensuring compliance with industry standards. Motivated to enhance operational efficiency and maintain safety protocols while collaborating with team members to drive continuous improvement.

Skills : Supplier Quality Assurance, Process Documentation, Statistical Analysis, Quality Improvement, Inspection Equipment Use

Description :

- Conduct routine inspections of products to ensure compliance with quality standards.

- Perform tests on materials and products to identify defects or inconsistencies.

- Conducted routine follow-up inspections to ensure compliance with quality standards.

- Executed analyses of in-process materials and finished goods to uphold quality benchmarks.

- Compiled documentation to support testing procedures, including data capture forms and equipment logs.

- Completed incoming quality inspections to verify parts conformance with blueprint specifications.

- Collaborated with quality team members to ensure adherence to testing protocols and final inspections on the production floor.

Experience

0-2 Years

Level

Entry Level

Education

AASQC

Qc Technician II Resume

Objective : Quality Control Technician with 2 years of experience in quality assurance and product testing within manufacturing environments. Skilled in executing precise inspections and adhering to compliance standards. Aiming to leverage analytical skills and a commitment to quality to enhance operational processes and ensure product excellence.

Skills : Data Analysis Software, Root Cause Analysis, Quality Assurance Techniques, Documentation Skills, Iso Standards Knowledge

Description :

- Executed comprehensive quality inspections of raw materials and finished products to ensure compliance with specifications.

- Conducted internal audits to verify adherence to GMP and HACCP protocols.

- Documented findings and collaborated with production teams to implement corrective actions.

- Performed laboratory tests on various products, analyzing pH, moisture content, and other quality metrics.

- Utilized laboratory equipment, including spectrophotometers and autoclaves, to conduct experiments.

- Maintained accurate records of testing results and compliance data.

- Participated in continuous improvement initiatives to enhance product quality and safety standards.

Experience

0-2 Years

Level

Entry Level

Education

ASQA

Associate Qc Technician Resume

Objective : Quality Control Technician with two years of specialized experience in quality assurance and product testing. Demonstrates proficiency in executing rigorous testing protocols, ensuring compliance with industry standards, and driving improvements in product quality. Eager to leverage strong analytical skills and a commitment to safety in a collaborative environment.

Skills : Product Sampling, Quality Control Plans, Supplier Quality Management, Laboratory Equipment Operation, Technical Writing, Regulatory Compliance

Description :

- Performed testing including GC and HPLC to ensure product quality.

- Coordinated the shipment of pre-shipment samples to customers as requested.

- Conducted monthly internal audits, monitored CCPs, and maintained accurate documentation.

- Updated SOPs for the quality control department.

- Audited team processes to expand knowledge of GCHPLC.

- Demonstrated strong communication skills while collaborating effectively with team members.

- Maintained compliance with safety protocols during testing procedures.

Experience

0-2 Years

Level

Entry Level

Education

A.S. QC

Assistant Qc Technician I Resume

Objective : Quality Control Technician with 2 years of experience in ensuring compliance and product quality within manufacturing settings. Proficient in executing precise inspections and testing protocols, utilizing calibrated tools for accurate measurements. Dedicated to promoting safety and efficiency while collaborating with teams to enhance operational processes and uphold industry standards.

Skills : Problem Solving, Analytical Thinking, Testing Procedures, Quality Control Software, Data Entry Accuracy, Inventory Management

Description :

- Conducted thorough visual and functional inspections on medical devices, ensuring compliance with quality standards.

- Verified final inspections and maintained accurate documentation for regulatory compliance.

- Implemented SOPs for testing procedures, adhering to GDP and GLP guidelines.

- Communicated quality issues effectively, facilitating prompt corrective actions.

- Utilized calibrated tools for precise measurements, enhancing inspection accuracy.

- Reviewed labels and manuals for correctness, ensuring clear communication of product information.

- Managed chemical product handling and disposal in accordance with safety regulations.

Experience

0-2 Years

Level

Entry Level

Education

AAS QC

Qc Technician Resume

Objective : Quality Control Technician with 2 years of experience in product testing and compliance verification. Skilled in utilizing precision measurement tools and techniques to ensure adherence to quality standards. Eager to enhance operational performance through effective collaboration and a commitment to continuous improvement.

Skills : Material Handling, Quality Audits, Training Skills, Product Testing, Customer Focus, Troubleshooting Skills

Description :

- Operated robotic welders and CNC machines, ensuring precise fabrication and assembly.

- Conducted thorough inspections of all incoming parts to verify compliance with customer specifications.

- Utilized dial indicators, micrometers, and calipers for accurate measurements of components.

- Performed quality assurance checks on finished products, ensuring adherence to quality standards.

- Executed salt spray tests on coated parts to assess durability.

- Maintained meticulous records of inspections and tests for compliance verification.

- Collaborated with engineering teams to address quality issues and implement corrective actions.

Experience

0-2 Years

Level

Entry Level

Education

AAS-QCT