Quality Inspector Resume

Summary : Accomplished Quality Inspector with 10 years of experience in manufacturing and quality control. Proven expertise in conducting inspections, analyzing defects, and implementing corrective actions. Demonstrates strong analytical skills and attention to detail, ensuring compliance with industry standards. Eager to contribute to a dynamic team focused on enhancing quality assurance processes.

Skills : Quality Control Methodologies, Regulatory Compliance, Defect Analysis, Inspection Reporting

Description :

- Developed and maintained a comprehensive database for tracking calibration and certification of over 120 lifting devices, ensuring OSHA compliance.

- Conducted thorough inspections across shop floor, receiving, and calibration lab, optimizing workflow and meeting customer demands.

- Performed first piece inspections on supplier and production parts, guaranteeing adherence to customer specifications.

- Collaborated with engineers to address and rectify issues with non-conforming parts.

- Managed the processing of accepted parts via Oracle, streamlining inventory management for production and shipment.

- Calibrated and certified measurement tools, ensuring accuracy for both shop use and customer orders.

- Proposed and evaluated new tooling and equipment options to enhance production efficiency and safety.

Experience

10+ Years

Level

Consultant

Education

AAS

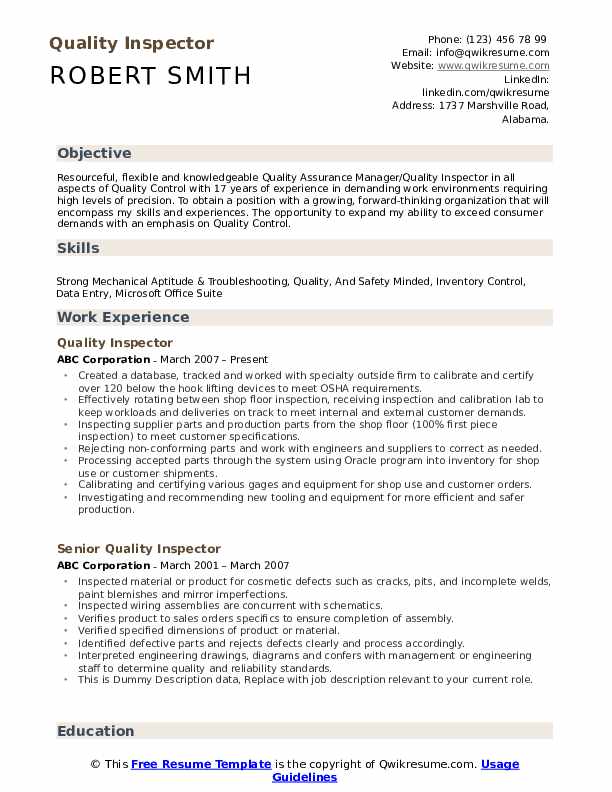

Quality Assurance Manager/Quality Inspector Resume

Summary : With a decade of experience as a Quality Inspector, I excel in ensuring product excellence through rigorous inspections and defect analysis. My commitment to quality and the ability to implement effective corrective actions have significantly enhanced operational standards. Passionate about driving improvements in quality assurance processes, I am ready to contribute to a results-oriented team.

Skills : Quality Management Software, Root Cause Analysis, Precision Measuring Instruments, Calibration Tools, Measurement Techniques

Description :

- Notified supervisors of deviations from specifications and machine malfunctions, facilitating timely corrective measures.

- Marked and stamped products to identify defects and ensure accurate grading.

- Conduct thorough inspections of products to ensure compliance with quality standards.

- Operated machinery that automatically sorted and inspected products for quality assurance.

- Measured product dimensions using precision instruments to verify compliance with specifications.

- Examined products and monitored processing to identify defects using sensory analysis.

- Performed maintenance on equipment to correct defects identified during inspections.

Experience

7-10 Years

Level

Senior

Education

B.S. QA

Lab Quality Inspector Resume

Headline : Dedicated Quality Inspector with 7 years of experience in manufacturing quality assurance. Skilled in performing detailed inspections, identifying defects, and implementing corrective measures to uphold product standards. My strong analytical abilities and commitment to best practices ensure compliance with quality regulations. I aim to enhance operational excellence within a collaborative team environment.

Skills : Data Analysis Software, Precision Measuring Tools, Manufacturing Equipment Operation, Visual Inspection Techniques, Technical Documentation Review

Description :

- Documented inspection results through detailed reports and spreadsheets to track compliance metrics.

- Employed precision measuring instruments, including micrometers and gauges, to verify product specifications and quality.

- Reviewed manufacturing and packaging records to ensure accuracy and adherence to quality standards.

- Analyzed data trends to identify areas for process improvement and quality enhancement.

- Collaborated with production teams to resolve quality issues and implement corrective actions.

- Ensured compliance with SOPs and QA guidelines during all inspection processes.

- Participated in internal audits to uphold quality assurance protocols and standards.

Experience

5-7 Years

Level

Executive

Education

B.S. QA

Warehouse Quality Inspector Resume

Summary : Driven Quality Inspector with a decade of experience in ensuring product integrity and compliance through meticulous inspections and rigorous testing. Expertise in identifying defects and implementing effective corrective measures to enhance quality standards. Committed to fostering a culture of continuous improvement and operational excellence within a collaborative team environment.

Skills : Quality Assurance Techniques, Product Testing, Six Sigma Principles, Quality Management Systems, Analytical Problem Solving

Description :

- Developed and maintained a comprehensive quality control program, ensuring compliance with industry standards.

- Conducted inspections and tests on materials and products to guarantee specifications are met.

- Maintained detailed records of inspections and quality control processes for accountability.

- Recommended improvements in standards and processes based on inspection outcomes.

- Alerted product managers of critical defects to ensure prompt action.

- Initiated continuous improvement activities leading to enhanced product quality and cost savings.

- Authored corporate documents outlining quality procedures and compliance standards.

Experience

10+ Years

Level

Management

Education

AAS

Junior Quality Inspector Resume

Objective : Quality Inspector with 5 years of experience in manufacturing quality control and inspection. Proficient in evaluating product specifications, identifying defects, and ensuring compliance with industry standards. Committed to enhancing quality assurance processes and fostering teamwork to achieve operational excellence.

Skills : Quality Control Techniques, Process Improvement, Preventive Actions, Efficiency Optimization, Attention To Detail

Description :

- Perform routine audits of production processes to ensure adherence to quality protocols.

- Verified in-process production by ensuring specifications and communicating adjustments to the production supervisor.

- Confirmed finished products by validating specifications and coordinating rework as necessary.

- Documented inspection results in quality logs and databases, summarizing rework and waste.

- Maintained measurement equipment by following procedures and coordinating repairs.

- Ensured a safe work environment by adhering to safety standards and regulations.

- Enhanced job knowledge by participating in training opportunities and reviewing technical publications.

Experience

2-5 Years

Level

Junior

Education

AAS QA

Sr. Quality Inspector Resume

Summary : With a decade of experience as a Quality Inspector, I specialize in enhancing product quality through meticulous inspections and effective defect resolution. My extensive background in quality assurance and compliance has driven significant improvements in operational performance. I look forward to leveraging my analytical skills and commitment to excellence in a challenging role within a progressive organization.

Skills : Quality Control Processes, Quality Control Standards, Quality Training And Development, Documentation And Reporting

Description :

- Ensured precise manufacturing processes for pharmaceuticals, maintaining high standards of quality control.

- Executed rigorous inspections and adhered to safety protocols, reinforcing compliance with all operational procedures.

- Monitored quality assurance processes, ensuring accuracy in documentation and adherence to regulations.

- Followed detailed manufacturing instructions, ensuring all specifications were met as per production tickets.

- Assisted management in the technical development of new product initiatives, enhancing overall quality processes.

- Operated and maintained machinery, ensuring a clean and safe working environment.

- Actively contributed to safety improvement programs, fostering a culture of safety awareness among staff.

Experience

10+ Years

Level

Consultant

Education

B.S. Quality Mgmt.

Quality Inspector III Resume

Summary : Quality Inspector with a decade of extensive experience in quality assurance and manufacturing processes. Adept at performing detailed inspections, identifying non-conformities, and implementing effective corrective actions to enhance product quality. My analytical mindset and commitment to industry standards ensure exceptional compliance and operational efficiency. Ready to drive continuous improvement within a forward-thinking team.

Skills : 5s Methodology, Lean Principles, Data Analysis In Excel, Defect Identification, Data Analysis

Description :

- Conducted thorough inspections of tubes for compliance with specifications using precision tools such as calipers and micrometers.

- Executed detailed process and system audits based on established standards, ensuring adherence to quality benchmarks.

- Coordinated the calibration and maintenance of all testing equipment, ensuring optimal performance and accuracy.

- Identified quality issues and recommended corrective actions, collaborating closely with supervisors for effective resolution.

- Provided critical feedback to assemblers regarding assembly accuracy and compliance with quality standards.

- Reviewed device history records for compliance with established documentation practices and protocols.

- Verified product conformance by comparing materials with established standards and specifications.

Experience

10+ Years

Level

Consultant

Education

AAS QA

Quality Inspector/Completions Center Resume

Headline : Quality Inspector with 7 years of hands-on experience in quality assurance and inspection processes. Proficient in executing detailed inspections, identifying defects, and ensuring compliance with regulatory standards. My analytical expertise and commitment to quality improvement drive operational efficiency and enhance product integrity. I seek to leverage my skills in a collaborative environment to promote excellence.

Skills : Microsoft Office Suite, Technical Drawing Interpretation, 3d Modeling And Inspection Systems, Iso 9001 Quality Management, Effective Written Communication

Description :

- Conducted comprehensive incoming inspections on components following established sampling plans and procedures.

- Collaborated with engineering to perform design verification testing, ensuring product specifications were met.

- Approved final products for lot release, maintaining stringent quality standards.

- Utilized various measurement tools to inspect assemblies and components accurately.

- Managed compliance issues, assisting functional management in identifying non-conformities.

- Worked cross-functionally to meet engineering milestones and production schedules effectively.

- Ensured correct labeling and performed in-process quality checks, including Tyvek pouch peel strength testing.

Experience

5-7 Years

Level

Executive

Education

AAS QA

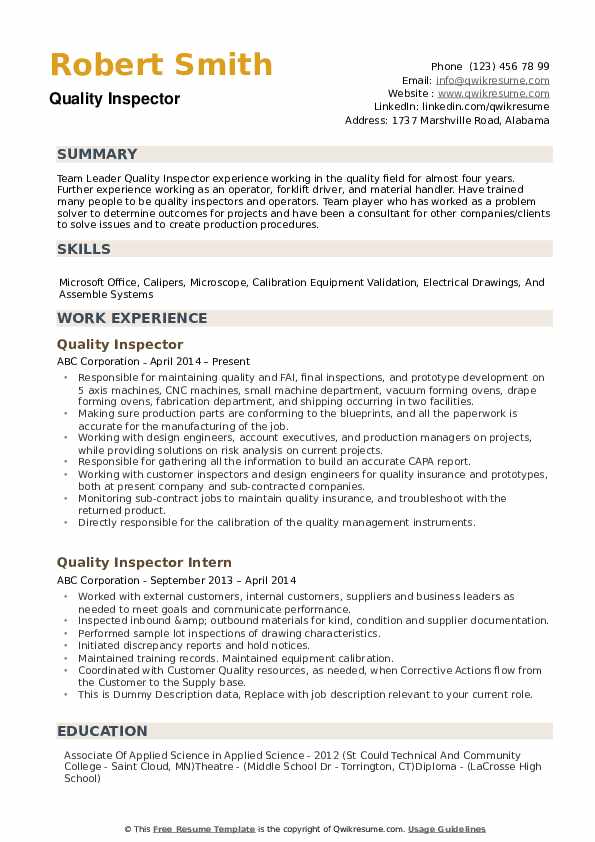

Team Leader Quality Inspector Resume

Objective : Quality Inspector with over 5 years of experience in quality assurance and inspection. Proven ability to conduct thorough evaluations, identify defects, and ensure compliance with stringent industry standards. Committed to enhancing operational processes and fostering a culture of quality within teams. Excited to leverage expertise to contribute to a forward-thinking organization focused on delivering superior products.

Skills : Inventory Management, Forklift Operation And Safety, Quality Auditing, Risk Assessment, Supplier Quality Assurance

Description :

- Performed comprehensive inspections of V6 and V8 engine blocks, identifying defects such as cracks and leaks prior to shipping.

- Utilized precision measuring tools to assess tolerances, ensuring adherence to company standards post-production.

- Collaborated with machine operators and management to address tolerance discrepancies and defect issues promptly.

- Initiated production improvement ideas that enhanced workflow efficiency and product quality.

- Executed minor machine maintenance to resolve operational issues, leveraging acquired technical knowledge.

- Drafted safety proposals and production process enhancements for team review.

- Monitored data outputs to detect internal defects in engine blocks, ensuring high-quality standards.

Experience

2-5 Years

Level

Junior

Education

AAS QA

Quality Inspector Resume

Headline : Quality Inspector with 7 years of specialized experience in quality assurance and compliance within manufacturing environments. Expertise in performing thorough inspections, identifying non-conformities, and driving corrective actions to enhance product integrity. Committed to optimizing processes and fostering teamwork to achieve superior quality standards.

Skills : Inspection Techniques, Optical Inspection Techniques, Calibration And Validation Techniques, Reading Electrical Schematics, Assembly And Systems Integration

Description :

- Conducted quality inspections across multiple manufacturing processes, ensuring compliance with industry standards.

- Reviewed and verified production parts against blueprints, maintaining accurate documentation for all manufacturing jobs.

- Collaborated with design engineers and production managers to perform risk analysis and provide actionable solutions.

- Compiled comprehensive CAPA reports to address quality issues and facilitate continuous improvement.

- Engaged with customer inspectors to validate prototypes and ensure quality assurance across subcontracted projects.

- Monitored subcontracted jobs, troubleshooting returned products to resolve quality concerns.

- Coordinated calibration and maintenance of quality management instruments to uphold standards.

Experience

5-7 Years

Level

Executive

Education

B.S. Quality Mgmt.