Quality Manager Resume

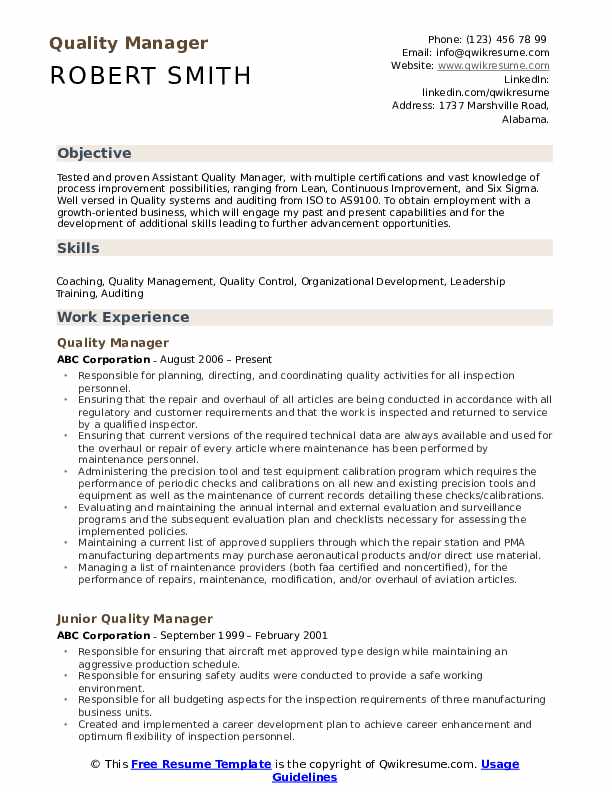

Summary : Dynamic Quality Manager with a decade of experience in driving quality assurance and continuous improvement initiatives across diverse manufacturing sectors. Adept at implementing ISO standards and Lean methodologies, enhancing operational efficiency, and fostering a culture of quality. Committed to delivering measurable results and elevating team performance to achieve strategic organizational goals.

Skills : Data Analysis, Team Leadership, Quality Assurance, Risk Management

Description :

- Planned and directed quality activities for inspection personnel, ensuring compliance with regulatory and customer requirements.

- Oversaw repair and overhaul processes, guaranteeing all work was inspected and returned to service by qualified inspectors.

- Managed calibration programs for precision tools and test equipment, maintaining accurate records of checks and calibrations.

- Evaluated internal and external quality systems to ensure effective implementation of policies.

- Maintained a list of approved suppliers for aeronautical products and materials, ensuring quality standards were met.

- Coordinated ongoing employee training programs, verifying participation and compliance with quality standards.

- Implemented corrective action plans to address quality issues, reducing discrepancies in inspections.

Experience

10+ Years

Level

Consultant

Education

B.S. Eng.

Software Quality Manager Resume

Objective : Quality Manager with 5 years of experience in enhancing quality assurance processes and driving continuous improvement initiatives within manufacturing environments. Skilled in implementing ISO standards and utilizing Lean methodologies to optimize operational efficiency. Passionate about fostering a quality-driven culture while delivering tangible results that align with organizational objectives.

Skills : Quality Management Software, Data Analysis Tools, Documentation Skills, Presentation Skills, Communication Skills

Description :

- Supported customers and end-users by addressing technical issues and implementing effective corrective actions.

- Designed, administered, and audited compliance of the QA system to AS9100 and Nadcap requirements.

- Implemented proactive quality management practices across all functional areas, including marketing and manufacturing.

- Facilitated quality tools training for the organization and supply chain, promoting best practices.

- Utilized 8D and root cause analysis methodologies to address quality issues.

- Compiled and presented quality reports detailing performance metrics, issues, and cost analysis.

- Drove quality improvements through effective launch strategies for new products.

Experience

2-5 Years

Level

Junior

Education

B.S. QA

Data And Quality Manager Resume

Summary : Accomplished Quality Manager with 10 years of experience in optimizing quality systems in manufacturing settings. Expert in deploying ISO standards and Lean practices to drive operational excellence and enhance product quality. Proven ability to lead cross-functional teams in continuous improvement initiatives that deliver significant cost reductions and elevate overall performance.

Skills : Microsoft Office Suite, Minitab Statistical Software, Autocad Design Software, Siemens Nx (formerly Unigraphics), Lean Six Sigma Methodologies

Description :

- Developed and implemented a corrective action policy that decreased technical support cases by 20 in three months.

- Facilitated root-cause analysis workshops, leading to a 30% reduction in warranty returns within four months.

- Created failure analysis reports to enhance communication among stakeholders and improve product reliability.

- Streamlined software and hardware designs to improve scalability and reuse, resulting in significant cost savings.

- Enhanced testing processes, achieving a 20% increase in accuracy and an 80% reduction in testing time.

- Successfully transferred over 10 new products into full-scale production with comprehensive documentation and testing plans.

- Championed continuous improvement efforts, resulting in increased operational efficiency and reduced lead times.

Experience

7-10 Years

Level

Senior

Education

B.S. Quality Mgmt.

Operations Manager/Quality Manager Resume

Summary : Accomplished Quality Manager with over 10 years of experience in leading quality improvement initiatives within high-tech manufacturing sectors. Expert in establishing and maintaining ISO compliance and Lean methodologies to enhance product integrity and operational efficiency. Passionate about driving cross-functional collaboration to achieve organizational excellence and deliver sustainable results.

Skills : Data Analysis Software, Benchmarking, Process Mapping, Product Testing, Quality Management Systems

Description :

- Leading quality investigations, ensuring comprehensive analysis and resolution of quality issues.

- Collaborating with production and development teams to enhance product supply and facilitate new product introductions.

- Establishing quality requirements with external suppliers through effective communication and negotiation.

- Integrating diverse teams to formulate and implement comprehensive quality procedures.

- Encouraging staff to adopt quality methodologies and drive cultural change.

- Overseeing raw material testing, in-process evaluations, and final product release processes.

- Managing compliance with labeling regulations as per 21 CFR 101.

Experience

7-10 Years

Level

Senior

Education

B.S. Quality Mgmt.

Regional Quality Manager Resume

Summary : Results-oriented Quality Manager with 10 years of extensive experience in steering quality assurance and process improvement initiatives within manufacturing environments. Proficient in implementing ISO standards and Lean methodologies to drive operational effectiveness. Dedicated to fostering a culture of continuous improvement and achieving strategic business objectives through measurable quality enhancements.

Skills : Process Improvement, Six Sigma Methodology, Regulatory Compliance, Sap Erp Systems, Lean Manufacturing Techniques

Description :

- Managed the quality management system to ensure compliance with AS9100C and ISO 9001 standards.

- Collaborated with AS9100C lead auditors to prepare quality documentation for audits.

- Drafted non-conformance reports and corrective action plans to enhance overall quality.

- Applied Lean Six Sigma principles to analyze non-conformances and implement root cause solutions.

- Updated process maps and quality documents to align with AS9100C standards and client requirements.

- Created comprehensive safety and training manuals to improve employee awareness of quality standards.

- Monitored shipment and return data to generate reports identifying areas for improvement in delivery timelines.

Experience

7-10 Years

Level

Senior

Education

B.S. QA

Corporate Quality Manager Resume

Headline : Strategic Quality Manager with 7 years of experience in enhancing quality control systems and driving process improvements in manufacturing environments. Proficient in implementing ISO standards and Lean methodologies to optimize operational performance. Focused on fostering a culture of excellence and achieving measurable quality enhancements that align with business objectives.

Skills : Hazard Analysis Critical Control Point, Food Safety Regulations Compliance, As/400 Systems Management, Lean Methodology

Description :

- Developed and implemented a corporate-wide API Spec Q1 compliance program, enhancing organizational standardization.

- Transitioned manual record-keeping systems to a digital platform, improving accessibility and accuracy.

- Represented management in QSI setup reviews and compliance audits, ensuring adherence to quality standards.

- Streamlined operational processes across inventory and manufacturing, reducing non-conformance production.

- Integrated an automated digital barcode system for precision instrument distribution, enhancing tracking accuracy.

- Optimized product line management processes, expediting quality staging prior to coating.

- Analyzed customer feedback to drive quality improvements, resulting in a 15% increase in customer satisfaction.

Experience

5-7 Years

Level

Executive

Education

BSQM

Industrial Quality Manager Resume

Summary : Proficient Quality Manager with over 10 years of extensive experience in elevating quality standards and driving continuous improvement in manufacturing environments. Expert in implementing ISO frameworks and Lean principles to streamline operations, enhance product quality, and foster a proactive quality culture. Focused on achieving strategic objectives through measurable performance improvements and team empowerment.

Skills : Quality Planning, Documentation Management, Problem Solving, Quality Standards, Internal Audits

Description :

- Established and maintained an effective ISO 9001 Quality Management System, ensuring compliance and continuous improvement.

- Led quality management activities, coordinating teams to meet project objectives and deliverables.

- Engaged with clients to resolve quality-related issues throughout the project lifecycle, from design to commissioning.

- Developed and revised quality plans, inspection strategies, and compliance documentation.

- Built a high-performing team of Quality Management engineers to meet project specifications and quality standards.

- Provided training and resources to contract personnel to ensure adherence to quality compliance and procedures.

- Implemented a risk management framework that identified and mitigated potential quality issues proactively.

Experience

7-10 Years

Level

Senior

Education

B.S. in QM

Operations And Quality Manager Resume

Objective : Results-driven Quality Manager with over 8 years of experience in implementing quality management systems and driving continuous improvement initiatives. Proven track record in reducing defects and enhancing product quality through effective team leadership and data analysis. Strong knowledge of ISO standards and regulatory compliance, committed to fostering a culture of quality and excellence within the organization.

Skills : Customer Satisfaction, Data-driven Decisions, Process Improvement Initiatives, Quality Documentation Management, Statistical Quality Control

Description :

- Develop and maintain departmental goals for quality assurance and continuous improvement.

- Coordinate the quality management system to ensure compliance with established standards.

- Promote a quality-driven culture through regular employee engagement initiatives.

- Implement corrective actions for customer complaints and product rejects.

- Utilize root cause analysis tools to address quality issues effectively.

- Manage the audit schedule to ensure compliance with quality standards.

- Led quality improvement projects that saved the company $200,000 annually through waste reduction.

Experience

2-5 Years

Level

Junior

Education

B.S. Quality Management

Maintenance Quality Manager Resume

Summary : Innovative Quality Manager with 10 years of expertise in enhancing quality processes within manufacturing. Proficient in implementing ISO standards and Lean methodologies to drive operational improvements. Known for fostering a quality-centric culture and achieving significant performance enhancements through strategic initiatives and team collaboration.

Skills : Root Cause Analysis, Cross-functional Team Leadership, Quality Training And Development, Process Reliability Improvement, Quality Planning And Strategy

Description :

- Implemented and maintained the Alcoa Business System, aligning it with Toyota's continuous improvement processes to enhance operational excellence.

- Trained and coached employees at all levels on problem-solving techniques and corrective action reporting.

- Facilitated quarterly Kaizen events to identify and execute process improvement opportunities with team involvement.

- Led weekly problem-solving sessions using 5-Why and 8D methodologies to establish root causes and develop effective corrective actions.

- Initiated daily flash communication meetings for cross-departmental updates on performance metrics and operational constraints.

- Managed a quality control department with 4 direct reports and 8 technicians, driving team performance and engagement.

- Oversaw customer and vendor claims, ensuring compliance with quality systems and operational excellence audits.

Experience

10+ Years

Level

Consultant

Education

B.S. Quality Management

Safety Manager-Quality Manager Resume

Summary : Innovative Quality Manager with a decade of experience in spearheading quality management systems and leading cross-functional teams to achieve operational excellence. Proficient in ISO compliance and Lean methodologies, driving continuous improvement and enhancing product quality. Eager to leverage extensive expertise to foster a culture of quality and deliver impactful results in a dynamic organization.

Skills : Six Sigma, Auditing Skills, Process Improvement Strategies, Quality Metrics Analysis, Statistical Process Control

Description :

- Developed and managed a robust quality management system achieving ISO 9001:2015 certification.

- Led continuous improvement initiatives, including value stream mapping, root cause analysis, and corrective action implementation.

- Ensured exceptional customer service by resolving quality concerns and executing effective action plans.

- Conducted thorough management reviews, internal audits, and compliance assessments to maintain quality standards.

- Authored and standardized processes and documentation, driving continuous improvement in engineering and manufacturing.

- Oversaw subcontractor quality assurance through rigorous audits and data analysis, ensuring compliance with quality metrics.

- Facilitated cross-functional teams in process enhancements, achieving significant operational improvements and cost savings.

Experience

10+ Years

Level

Consultant

Education

B.S. in Q.M.