Senior Production Engineer Resume

Headline : To utilize extensive Lean, Six Sigma, Quality, Operational, Supply Chain, and Leadership experience in a challenging position where can positively impact the organization.

Skills : Management, Production, Organizing.

Description :

- Communicates with vendors for the procurement of necessary equipment or to source equipment which may result in a beneficial ROI (return-on-investment) for the Production department.

- Uses knowledge and experience to analyze all aspects of quoted equipment.

- Makes recommendations to customize equipment to suit company needs, reducing downtime and increasing efficiency.

- Performs line trials and/or Factory acceptance tests with prospective equipment to verify that all components and processes perform as required.

- Reviews and determines necessary equipment and change-parts with Production maintenance personnel for all new products as well as existing products.

- Works with vendors to obtain necessary items at lowest cost while still being compatible for Production operations.

- Provides technical assistance to Production/Mechanical teams regarding quality issues and technical/mechanical issues.

- Serves as a liaison with various vendors for identifying and solving mechanical and technical issues with Production equipment.

Experience

5-7 Years

Level

Executive

Education

Bachelor's

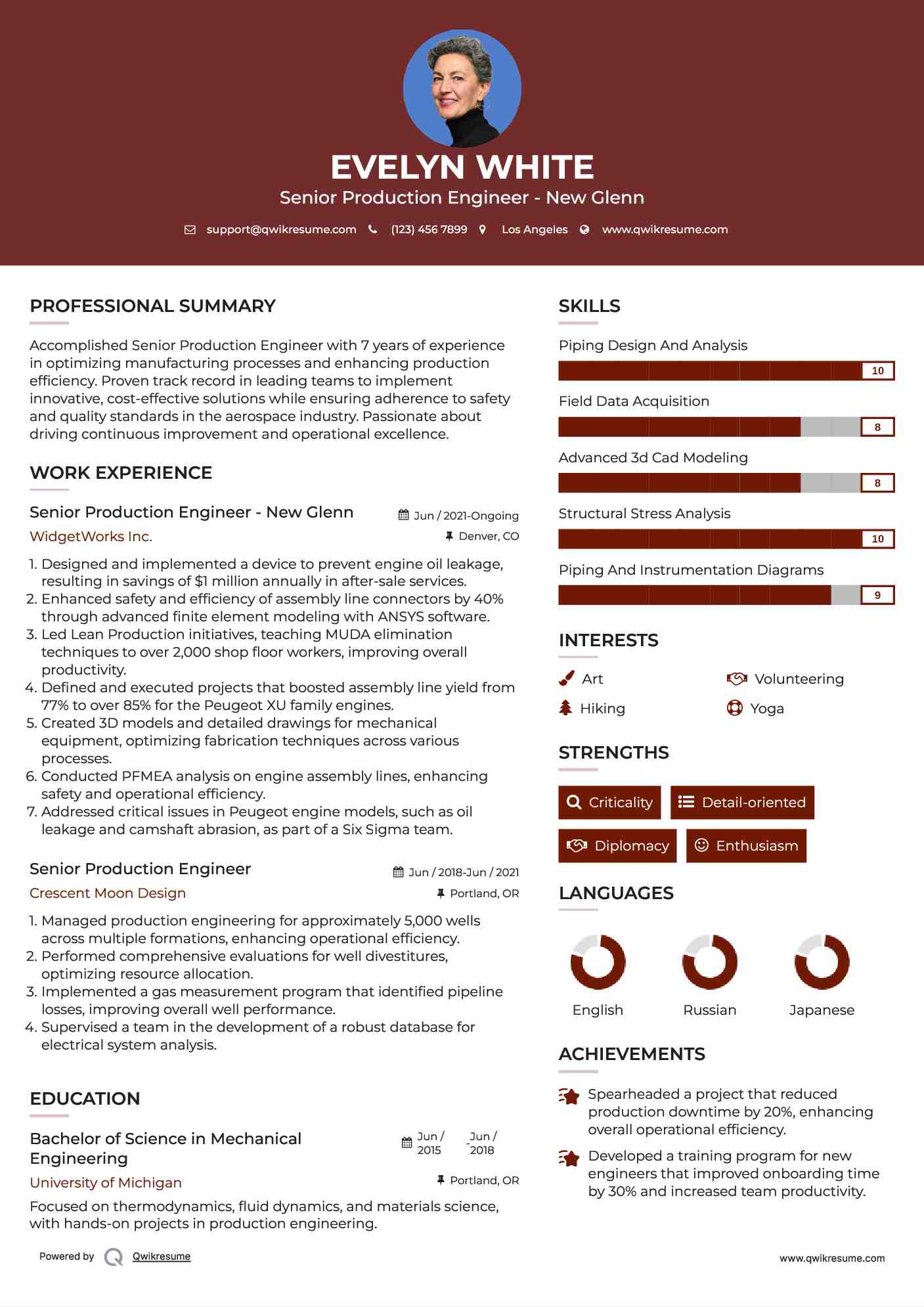

Jr. Senior Production Engineer Resume

Objective : Senior Production Engineer with over 11 years of experience in design, production, manufacturing, piping and stress analysis and having successfully met project standards and deadlines.

Skills : Piping, Field Detailed Survey, 3D Modeling, Stress Analysis, P&ID, Isometric, Pipe Support Detail, BOM/MTO, Lean And SixSigma Methodologies.

Description :

- Designed and built device to prevent engine oil leakage and improve production, generating savings of USD $1,000,000 per year in after-sale services.

- Improved safety, efficiency and reduced weight of connectors between assembly line conveyors and PEYKAN engine by 40% through finite element modeling and analysis with FEM & ANSYS software.

- Led Lean Production and MUDA (waste) elimination by implementing of MUDA elimination activities and Kaizen methodology on the shop floor, and taught Lean Production techniques to 2,000 shop floor workers and technicians by conducting hour-long classes for groups of 40 daily.

- Defined and implemented projects to improve the production efficiency, increasing the Peugeot XU family engine assembly line yield from 77% to over 85%.

- Designed 3D models of mechanical equipment and tools and detailed drawings from solid models for a variety of fabrication techniques, i.e.CNC / Manual Machining, welding, and sheet metal forming.

- Analyzed potential failure modes within the system in the engine assembly line (PFMEA: Process Failure Mode and Effects Analysis) creating a safer and more efficient assembly line.

- Actively reduced Peugeot engine (XU7/L3-JP4 models) issues including oil leakage of the crankshaft seal and camshaft abrasion as a six sigma member of the power train department.

- Led 7-member engine management system (EMS) team on fuel reduction and other fuel-related projects.

Experience

2-5 Years

Level

Junior

Education

Engineering

Senior Production Engineer/Analyst Resume

Objective : To be employed by a progressive oil and gas company in a challenging upper management or engineering position where analytical, problem solving, teamwork and leadership skills can be used to maximize company profitability.

Skills : Microsoft Office, Economic Analysis, Petroleum Engineering, Management.

Description :

- Works in a role that requires me to manage the East Texas Assets similar to an operations manager.

- Manages the workovers and recompletions we have going on.

- Designs all of the completions we do and write all the procedures and work closely with the production superintendent in the field on workovers, recompletions, and gas lift optimization.

- Works in a coil tubing operation and well intervention engineer role in our Eagle Ford Shale acreage in South Texas as well.

- Responsible for coil toe preps for the completions engineers then responsible for the coiled tubing drill out operation once the well is completed.

- Works on the procedures for coiled tubing fishing operations for well interventions when fishing ops are needed.

- Supports South Texas Production Engineer when needed with procedures and more complicated well intervention workovers.

Experience

2-5 Years

Level

Junior

Education

Bachelor's

Senior Production Engineer I Resume

Objective : Assigned to specific production units the Senior Production Engineer provides chemical engineering expertise to deliver optimum performance of Ascend's process units in the areas of capacity, yields, energy, safety, and quality. The position works under the direction of the site Production Engineering Manager and works closely with professionals in Technology, Project Engineering, and Manufacturing.

Skills : Piping, Field Detailed Survey, 3D Modeling, Stress Analysis, P&ID, Isometric, Pipe Support Detail, BOM/MTO, Lean And SixSigma Methodologies.

Description :

- Works closely with Mfg. Engineers, Control Engineers, and Operations to optimize the economic performance of the assigned process unit(s) by improving yields or reducing energy and other usages.

- Works with Operations, Maintenance, and Reliability professionals to improve the reliability of the process unit(s) and to maximize OEE.

- Actively supports the site & area safety programs via participation (or leadership) in PHAs, LOPAs, MOC, incident investigations, resolution of action items, and other activities to ensure safe operation and regulatory compliance.

- Serves as the unit production expert and provides technical counsel and troubleshooting assistance to Mfg. Engineers and Operations as needed to deliver planned performance.

- Works with the Mfg. Engineers and Operations to maintain all process documentation up-to-date.

- Serves as Mfg. Representative on capital project teams.

- Provides process design information for small capital and/or expense projects.

- Generates innovative ideas for process improvements and works with Technology, Process Engineering, and Project Engineering to screen such ideas.

Experience

2-5 Years

Level

Junior

Education

Engineering

Senior Production Engineer II Resume

Headline : A Senior Production Engineer position that utilizes analytical aspects within this field. Develop, guide, and coach salaried and hourly team members to achieve high performance in the areas of safety, quality, delivery and cost.

Skills : Test Engineer, Reliability Engineer.

Description :

- Maintained configuration control of the engineering drawings of all Collective Protection (CP) production equipment.

- Served as the Tri-Service Configuration Control Board (CCB) Chairman to control the engineer drawings of all fielded Collective Protection (CP) equipment.

- Controlled and managed CP engineering drawings through the ECBC drawings database, including Field Hospitals and other tent shelters such as M28, chemically protective filters such as M48, M98, Hermetically Sealed Filter Canister (HSFC), and other CP equipment.

- Prepared Engineering Change Proposals (ECP) to make any necessary changes to engineering drawings for improvements or necessary fixes or changes.

- Ensured needed Special Packaging Instructions (SPI) were prepared by packaging specialists and updated all SPIs in the ECBC engineering drawings database to maintain configuration control.

- Utilized production line boards to collect information on value stream performance, issue identification and problem resolution.

- Ensured information is passed on to the following shift and management.

Experience

5-7 Years

Level

Executive

Education

Engineering

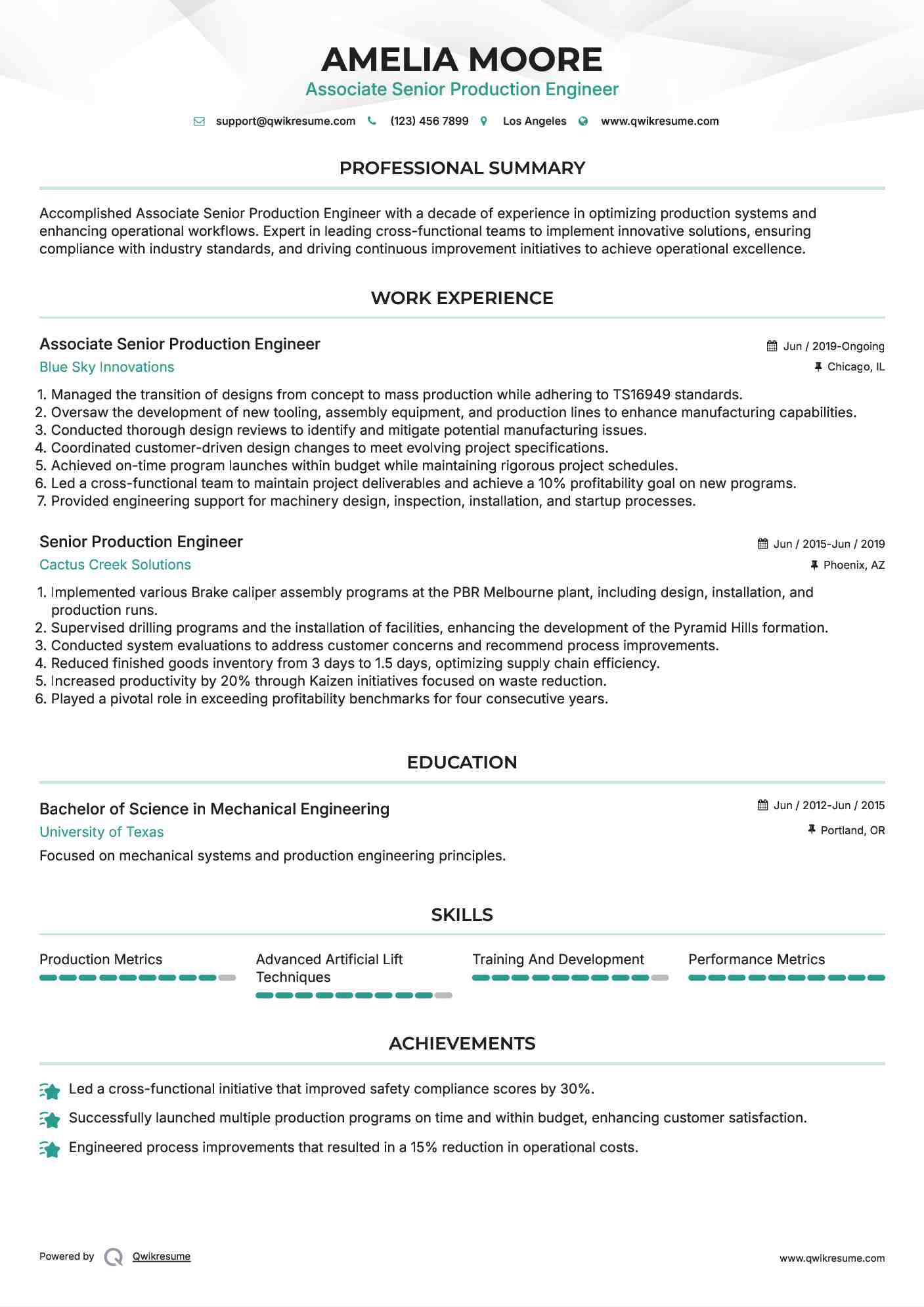

Senior Production Engineer III Resume

Summary : To obtain a challenging and gratifying Senior Production Engineer position were growth, stability and employee satisfaction is second nature.

Skills : Field Operations And Optimization, Artificial Lift Design And Optimization, Reserves And Acquisition Evaluations.

Description :

- Takes programs from drawings to mass production and finally through till obsolescence following TS16949 guidelines.

- Encompasses building new injection tooling, new assembly equipment, welding equipment with tooling, and assembly lines.

- Reviews all designs for potential manufacturing problems and request changes.

- Implements customer design changes according to customers needs.

- Launches program on time and within budget while submitting schedules to customers.

- Maintains project schedule and deliverables Equipment justifications Manage a cross-functional team Prepare documentation, control and distribute Control all engineering functions for a satellite plant Mentor engineers using knowledge and expertise Exceed companies 10% profitability goal on new programs.

- Responsible for new machinery design assistance and review, design changes, buffs, inspection, installation and startups.

Experience

7-10 Years

Level

Management

Education

Bachelor's

Asst. Senior Production Engineer Resume

Objective : Summary More than 20 years of extensive in-depth experience in the field of Production Engineering. Demonstrated experience in Structural and Modular fabrication to the refining, gas processing, and petrochemical industries. Highly accomplished Commissioning Engineer in the site execution of Pre-commissioning and Commissioning activities as well as Start-up and Operations specifically in the Oil & Gas and Petrochemical industries.

Skills : Test Engineer, Reliability Engineer.

Description :

- Responsible to manage and maintain the deployment activities and schedule starting with pilot sites leading up to full deployment

- Creates and maintains a go-live plan; this includes comprehensive checklist(s) and detailed tasks incorporated into an Integrated Master Schedule

- Oversights of environment provisioning activities through an iterative and phased delivery model

- Conducts deployment readiness reviews, milestone reviews and go/no-go reviews

- Works closely with the Technical Operations and System Engineer teams to understand impacts of branches and code merges as well as environment set up activities

- Works with the Configuration team to maintain a release repository; manage key artifacts to include build and release procedures and dependencies

- Coordinates deployment activities as it relates to standing up and supporting a Help Desk; Tier I, II and III

- Provide release, environment provisioning, and deployment status reporting to the leadership team

- Recommends and implements best practices

- Supports Training and Production Support teams as needed

Experience

2-5 Years

Level

Junior

Education

Engineering

Associate Senior Production Engineer Resume

Headline : Worked in Strategic Sourcing on machined sand & die castings and forged assemblies, laser-cut and stamped parts. Plans and implements Quality Assurance programs designed to ensure continuous production of products consistent with established standards

Skills : Operations, Manufacturing Management Quality Manager P&L Responsibility Sales Coordination and Support.

Description :

- Responsible for Operations and production including writing workover procedures, communication with workover supervisors and consultants.

- Utilized S-rod for SRP designs.

- Supervised multiple well repairs where we installed Enventure patches to repair liner failures.

- Responsible for Day to day production optimization and problem solving with production foreman, well testers, and pumpers.

- Advised other production engineers with day to day issues, and ongoing projects.

- Installed gas lift and supervised start-ups and operation.

- Selected and installed Rotaflex, and ESPs this quarter.

Experience

5-7 Years

Level

Executive

Education

Bachelor's

Senior Production Engineer/Consultant Resume

Summary : Senior Production Engineer with extensive experience in implementing workover and completion programs within multiple basins to optimize production and operating expense. A flexible decision -maker with strong analytical and communication skills. Strong production and operations background. Knowledgeable in: Hydraulic Fracturing Design Matrix Acidizing Design Primary and Remedial Cement Design Rod lift Design Using Diagnostic Software Production Predictive Analysis NODAL Analysis.

Skills : Supply,planniing And Scheduling.

Description :

- Worked within a diverse team to develop, market, and plan for growth of microseismic mapping of hydraulic fracture stimulation treatments.

- Projects mostly involved the unconventional shale formations.

- Responsible for providing stimulation interpretation and recommendations based on the acoustic information.

- Increased revenue $363 M to $750 M.

- Provided engineering support for the testing and marketing of new internal products and services.

- Captured the unique value through stimulation and production analysis.

- Assisted in the development of the initial pricing model.

Experience

7-10 Years

Level

Consultant

Education

Bachelor's

Senior Production Engineer Resume

Objective : Driven professional with extensive technical and management experience and specialization in innovative process improvement and automation. Seeking a position to leverage and further track record of excellence, collaborative success, and shared growth.

Skills : Management, Organizing.

Description :

- Responsible for daily escalation resolutions, custom processes, and operational tasks.

- Significantly automated daily tasks, leading to substantial increase in work-life balance for team.

- Led technical resource on major company-wide escalations.

- Created and customized existing stored procedures, scripts, and other database objects.

- Created new VBS applications to automate other departments' tasks.

- Provided custom report output to all levels of upper management, based on self-created query automation across more than 400 databases.

- Recruited and mentored junior team members.

Experience

0-2 Years

Level

Entry Level

Education

AS