Senior Quality Engineer / Assistant Quality Manager Resume

Summary : Dynamic Senior Quality Engineer with a decade of experience in the automotive sector, excelling in quality assurance, supplier development, and process optimization. Proven track record in leading cross-functional teams to enhance product quality and customer satisfaction. Eager to leverage extensive expertise in quality systems and project management to drive continuous improvement in a challenging environment.

Skills : As9100 Quality Management System, Quality Engineering Software, Data Analysis And Reporting, Enterprise Resource Planning

Description :

- Led quality engineering initiatives for automotive products, ensuring compliance with customer specifications for over 50 million parts annually.

- Facilitated cross-functional teams to address root causes of product failures, implementing corrective actions that significantly reduced defect rates.

- Initiated warranty reduction projects, enhancing customer satisfaction metrics and optimizing warranty costs.

- Presented comprehensive quality reports to senior management and key stakeholders, driving informed decision-making.

- Conducted annual audits for manufacturing facilities and suppliers, ensuring adherence to quality standards.

- Organized product workshops at client sites, educating teams on quality control measures and defect prevention.

- Implemented Kaizen methodologies to foster continuous improvement and waste reduction across processes.

Experience

7-10 Years

Level

Senior

Education

B.Sc. Eng.

Senior Quality Engineer/Quality Engineer Resume

Summary : Accomplished Senior Quality Engineer with over a decade of experience in diverse manufacturing sectors including automotive and medical devices. Demonstrated expertise in quality systems, process optimization, and cross-functional leadership to enhance product integrity. Committed to driving compliance and continuous improvement through effective quality management strategies.

Skills : Risk Assessment, Lean Manufacturing Techniques, Fmea And Root Cause Analysis, Supplier Quality Assurance, Corrective And Preventive Actions

Description :

- Managed a team of Quality Technicians and Inspectors to address and resolve quality issues in medical device manufacturing.

- Oversaw sterilization and environmental monitoring programs, ensuring compliance with industry standards.

- Recognized for strategic problem-solving skills in diagnosing and planning quality interventions.

- Utilized strong organizational skills to maintain production efficiency while resolving quality challenges.

- Reduced the backlog of non-compliance reports by 10 within a 90-day period.

- Revamped the Bioburden monitoring process, enhancing usability and compliance.

- Established precise calibration limits for instruments, effectively addressing compliance issues.

Experience

10+ Years

Level

Management

Education

BSE

Senior Quality Engineer III Resume

Summary : Innovative Senior Quality Engineer with a robust 10-year track record in quality assurance and process enhancement within the automotive industry. Skilled in driving cross-functional collaboration to elevate product quality and compliance. Passionate about utilizing extensive expertise in quality systems and strategic problem-solving to foster continuous improvement and operational excellence.

Skills : Data Analysis, Test Management Tools, Scripting Languages, Functional Testing, System Testing

Description :

- Directed APQP initiatives for new product launches, ensuring timely PPAP submissions and compliance with corporate standards.

- Served as ISO 9000 representative for the Amarillo plant, driving quality initiatives and reporting to corporate management.

- Facilitated cross-functional teams in problem-solving and continuous improvement efforts to meet plant performance indicators.

- Implemented customer complaints reduction projects, achieving a 60% decrease in reported issues.

- Developed and executed PFMEA, Control Plans, and Quality Inspections for all manufacturing processes.

- Supported supplier development initiatives to ensure alignment with quality standards and expectations.

- Established a robust Quality Management System, achieving ISO 9001 certification and enhancing documentation control.

Experience

10+ Years

Level

Consultant

Education

B.S.E.

Senior Quality Engineer I Resume

Summary : Seasoned Senior Quality Engineer with 10 years of experience optimizing quality assurance and supplier processes in the manufacturing sector. Proven ability to lead diverse teams toward achieving operational excellence and enhancing product reliability. Dedicated to implementing innovative quality management strategies that foster continuous improvement and drive customer satisfaction.

Skills : Risk Assessment And Mitigation, Lean Manufacturing And Six Sigma, Failure Mode And Effects Analysis (fmea), Code Review, Software Testing Life Cycle

Description :

- Directed continuous improvement initiatives, leveraging customer feedback to reduce error rates and enhance quality and productivity.

- Conducted benchmarking of competitor products to identify internal process enhancements, resulting in decreased external failures.

- Established and nurtured positive relationships with suppliers to ensure quality compliance and effective communication.

- Performed regular audits of Supplier Quality Systems to verify adherence to quality requirements.

- Develop and implement quality assurance strategies to enhance product reliability.

- Authored Product Development Proposals that improved product quality, leading to a 55% decrease in customer complaints.

- Utilized hypothesis testing and experimental design to eliminate failure modes, resulting in significant cost savings and improved customer satisfaction.

Experience

10+ Years

Level

Management

Education

B.S. in Q.E.

Senior Quality Engineering Aide Resume

Headline : Accomplished Senior Quality Engineer with 7 years of experience in quality assurance and process improvement across diverse manufacturing environments. Adept at leading cross-functional teams to enhance product reliability and compliance. Passionate about leveraging strong analytical skills and quality management systems to drive operational excellence and foster a culture of continuous improvement.

Skills : Quality Assurance Management, Cross-functional Team Leadership, Selenium Webdriver, Defect Tracking, Performance Testing

Description :

- Developed and managed quality assurance protocols for foundry operations, supervising a team of 50 employees.

- Oversaw the review and disposition of casting quality, ensuring adherence to industry standards.

- Established a sand testing laboratory to enhance material quality assessment processes.

- Created documentation procedures to effectively communicate testing results facility-wide.

- Implemented real-time sandbinder testing, reducing mold defects by 80%.

- Increased on-time delivery by 15% through effective supervision and process optimization.

- Achieved AAR certification by developing and implementing comprehensive work standards for critical processes.

Experience

5-7 Years

Level

Executive

Education

B.S. Eng.

Senior Quality Engineer II Resume

Summary : Accomplished Senior Quality Engineer with 10 years of experience specializing in quality assurance, compliance, and process optimization across various manufacturing sectors. Demonstrated success in leading teams to enhance product quality and drive continuous improvement initiatives. Ready to apply extensive knowledge of quality management systems to deliver exceptional results in dynamic environments.

Skills : Root Cause Analysis, Cross-functional Collaboration, Statistical Process Control, Team Collaboration

Description :

- Developed a comprehensive quality control framework for construction projects, enhancing safety compliance and operational efficiency.

- Created a performance tracking tool for safety inspections, resulting in improved compliance rates and reduced incidents.

- Authored quarterly newsletters to disseminate safety insights and regulatory updates, fostering a culture of safety awareness.

- Conducted trend analyses for construction safety inspections, identifying key areas for improvement.

- Collaborated with design engineers to optimize construction processes based on quality insights.

- Reviewed and assessed design submittals and constructability assessments for compliance with quality standards.

- Prepared white papers to drive continuous improvement in safety methodologies across projects.

Experience

10+ Years

Level

Consultant

Education

B.S. Eng.

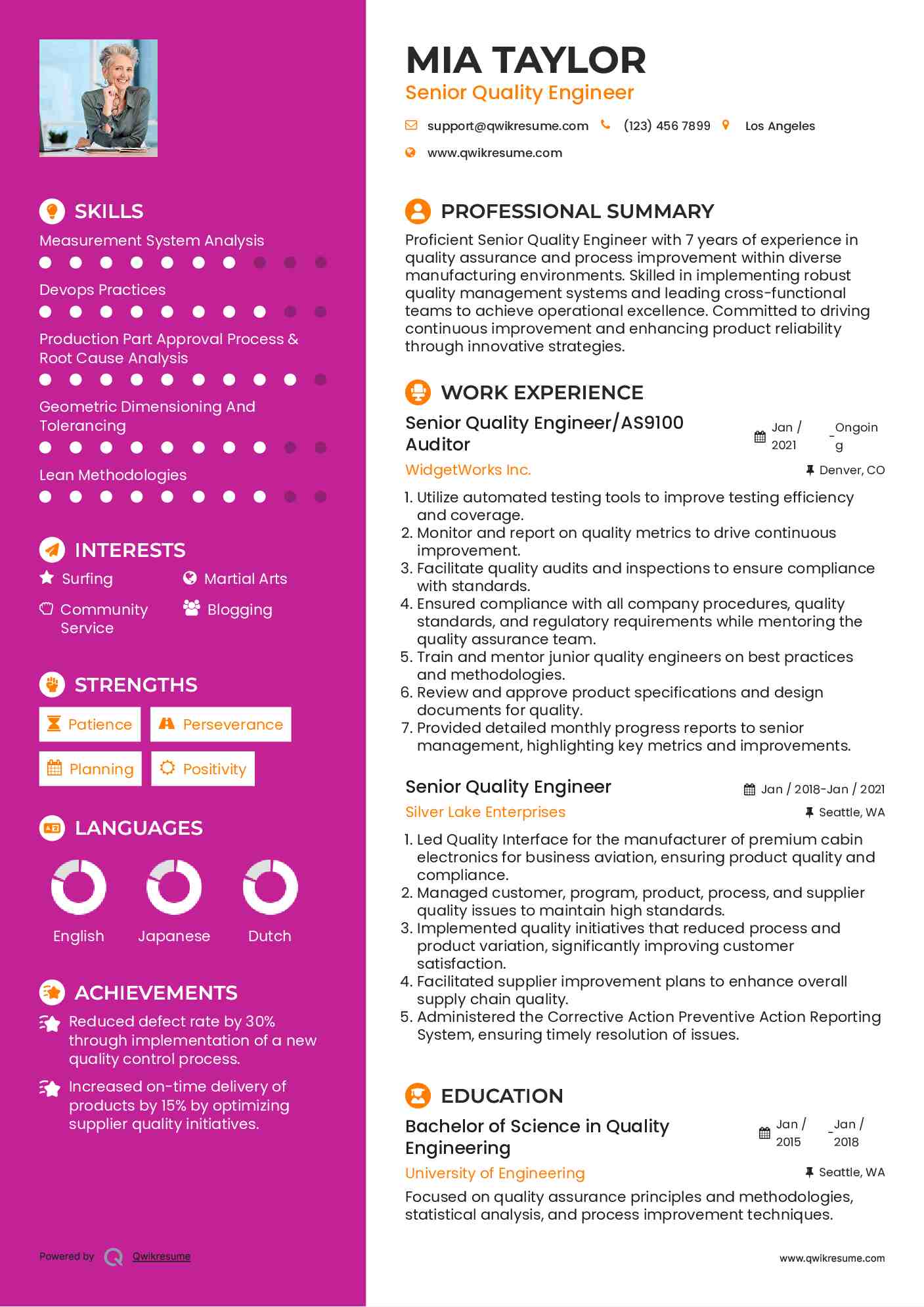

Senior Quality Engineer/AS9100 Auditor Resume

Headline : Proficient Senior Quality Engineer with 7 years of experience in quality assurance and process improvement within diverse manufacturing environments. Skilled in implementing robust quality management systems and leading cross-functional teams to achieve operational excellence. Committed to driving continuous improvement and enhancing product reliability through innovative strategies.

Skills : Measurement System Analysis, Devops Practices, Production Part Approval Process & Root Cause Analysis, Geometric Dimensioning And Tolerancing, Lean Methodologies

Description :

- Utilize automated testing tools to improve testing efficiency and coverage.

- Monitor and report on quality metrics to drive continuous improvement.

- Facilitate quality audits and inspections to ensure compliance with standards.

- Ensured compliance with all company procedures, quality standards, and regulatory requirements while mentoring the quality assurance team.

- Train and mentor junior quality engineers on best practices and methodologies.

- Review and approve product specifications and design documents for quality.

- Provided detailed monthly progress reports to senior management, highlighting key metrics and improvements.

Experience

5-7 Years

Level

Executive

Education

BSQE

Lead/Senior Quality Engineer Resume

Summary : Versatile Senior Quality Engineer with a decade of experience in quality assurance, process improvement, and supplier management across various industries. Adept at implementing innovative quality systems and leading teams to drive operational excellence. Committed to enhancing product integrity and ensuring compliance while fostering a culture of continuous improvement.

Skills : Test Automation, Regression Testing, Software Testing, Agile Methodologies, Test Planning

Description :

- Oversee quality assurance for pharmaceutical production, ensuring compliance with regulatory standards.

- Evaluate and approve validation protocols, ensuring robust quality systems are in place.

- Conduct investigations to identify root causes of quality issues and implement corrective actions.

- Ensure thorough investigation of quality complaints, adhering to SOPs for documentation.

- Review and approve technical documents, ensuring accuracy and compliance.

- Provide engineering support to enhance the company's quality systems and processes.

- Facilitate customer complaint resolution in line with regulatory requirements.

Experience

10+ Years

Level

Management

Education

B.S. in QE

Senior Quality Engineer/Quality Manager Resume

Summary : Results-driven Senior Quality Engineer with over 8 years of experience in software testing and quality assurance. Proven expertise in developing and implementing test strategies, automated testing frameworks, and quality metrics. Strong analytical skills with a focus on continuous improvement and defect prevention. Adept at collaborating with cross-functional teams to ensure product quality and compliance with industry standards.

Skills : Quality Management, Cross-functional Leadership, Process Improvement, Quality Standards, Junit Framework

Description :

- Manage a comprehensive quality system ensuring compliance with ISO 9001 standards for electro-mechanical thermocouple sensors.

- Supervise a team of six quality technicians, overseeing specification verification, quality testing, and root cause analysis.

- Lead union production teams in all aspects of electro-mechanical manufacturing to ensure adherence to quality standards.

- Develop and manage demand-based production schedules for high-volume assembly lines.

- Achieved an average cost savings of $100k by applying Demand Flow Technology to optimize operations and eliminate inefficiencies.

- Monitor material usage, control inventory levels, and coordinate logistics for timely delivery.

- Conduct comprehensive training programs for staff on quality processes and best practices.

Experience

10+ Years

Level

Consultant

Education

BSE

Senior Quality Engineer/Supervisor Resume

Summary : Accomplished Senior Quality Engineer with 10 years of experience in quality assurance and process optimization across multiple manufacturing sectors. Proven ability to enhance product quality and compliance through robust quality management systems. Passionate about leading teams to achieve operational excellence and implementing innovative strategies for continuous improvement.

Skills : Quality Assurance Protocols, Nadcap Accreditation Standards, Lead Auditor, Attention To Detail

Description :

- Reviewed quality requirements for new power supply products, ensuring compliance with customer specifications and industry standards.

- Ensured timely shipment of over $25 million in products while maintaining the highest quality standards.

- Initiated and implemented NADCAP standards in electronics and electrical harnessing, improving supplier quality.

- Maintained AS9100 REV C standards in the Power Conversion business unit, ensuring compliance and operational excellence.

- Performed 30 AS9102 First Article Inspections using Visual FAIR software, guaranteeing product quality from the start.

- Participated in four kaizen events that led to the successful implementation of 5S and the overhaul of the Calibration area.

- Conducted comprehensive training on non-conformance material, CAPA, and Material Purge for all associates, enhancing overall quality awareness.

Experience

10+ Years

Level

Management

Education

BSE

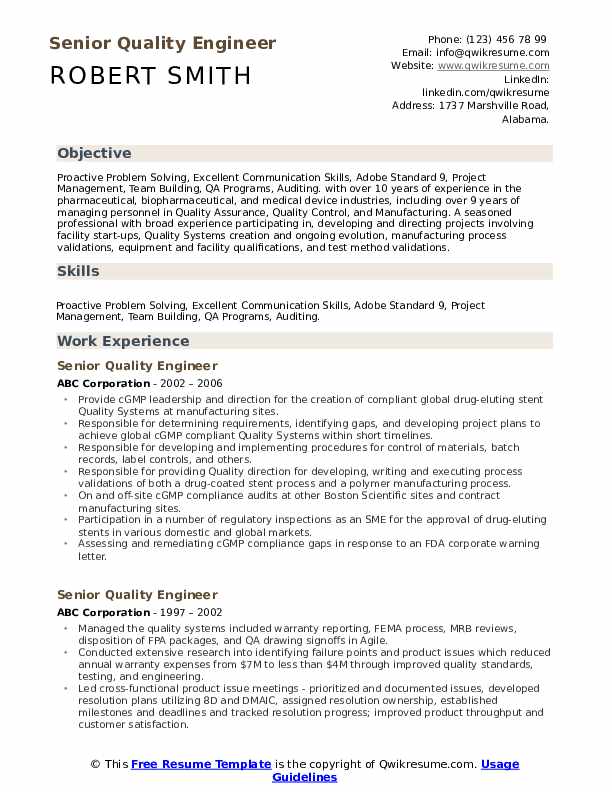

Senior Quality Engineer Resume

Summary : Results-oriented Senior Quality Engineer with 10 years of experience in quality assurance and compliance within the pharmaceutical and medical device industries. Expertise in developing robust quality systems, driving process improvements, and leading cross-functional teams to enhance product integrity. Committed to fostering a culture of quality and continuous improvement to achieve operational excellence.

Skills : Continuous Integration, Test Case Design, Software Development Life Cycle, Quality Management Systems, Leadership And Mentoring

Description :

- Coordinate with suppliers to ensure quality standards are upheld in materials.

- Identify requirements, assess gaps, and develop strategic project plans to achieve global cGMP compliance within tight deadlines.

- Develop and implement procedures for material control, batch record management, and labeling to ensure quality standards.

- Guide the development, writing, and execution of process validations for drug-coated stent and polymer manufacturing processes.

- Lead quality improvement projects using Six Sigma and Lean methodologies.

- Serve as a Subject Matter Expert during regulatory inspections for drug-eluting stents in domestic and global markets.

- Assess and remediate cGMP compliance gaps in response to FDA findings, ensuring adherence to industry regulations.

Experience

7-10 Years

Level

Management

Education

B.S. in QE