Senior Validation Engineer Resume

Summary : Senior Validation Engineer with strong knowledge of Documentum, Service Now, Trackwise Change Management and Agile PLM. Strong Knowledge of Functional Risk Assessments. Involved in End to End Validation deliverables. Seeking a position to utilize the skills and abilities in the Industry that offers professional growth while being productive, innovative and flexible.

Skills : Validation, Minitab, Excel, ISO, Statistics, Tally, Microsoft Excel, Photoshop

Description :

- Perform commissioning and validation for a new manufacturing facility and author qualification protocols.

- Develop risk assessments, deviation responses, and summary reports for qualification activities.

- Execute equipment validation for facilities, cold rooms, HVAC, CIP, COP, critical utilities and laboratory equipment.

- Executed temperature mapping studies and engineering test plans prior to validation activities.

- Designed experiments and authored protocols, summary documentation, change controls and regulatory documentation.

- Managed deviation and non-conformance reports and investigations. Scheduled project activities in concert with the production schedule while meeting all milestones.

- Implemented and executed qualification procedures for chromatography systems, clean steam, dispensing stations, WFI, HVAC, CIP, SIP, COP, UF/DF Skids, cold storage rooms, fume hoods, floor scales, and critical utilities.

- Performed a variety of general validation activities, including the IQ/OQ/PQ activities for equipment such as agitators/mixers, bench scales, centrifuges, and storage vessels.

Experience

7-10 Years

Level

Senior

Education

Bachelors Of Science

Verification And Validation Engineer Resume

Headline : Overall 6+ years of experience as a Verification And Validation Engineer and extensive experience in Computer System Validation and Process Validation in compliance with FDA standards. Good knowledge of the Software Development Life Cycle (SDLC), familiar with Software Methodologies like Waterfall, Spiral, V-Model, and Agile in relation to development and testing.

Skills : Data Migration, Risk Assessment, DRQ, DMQ, Validation, OQ, PQ, Complaince

Description :

- Performed risk management activities using Failure Mode Effect Analysis (FMEA) techniques to identify potential failure modes on pharmaceutical and medical device manufacturing equipment.

- Established and maintained procedures for identifying valid statistical techniques required for establishing, controlling, and verifying the acceptability of process capability.

- Performed process capability studies with Ppk & Cpk indexes to analyze processes using statistical software.

- Authored protocols and reports; specific to the validation of test methods Experienced in working with suppliers for the development of inspection methods Responsible for initiating, implementing and completing change control, deviations, investigations, impact/risk assessments, root cause analysis, and CAPAs.

- Responsible for maintaining Quality System Regulations (Part 820) and Regulatory Standards (ISO) Responsible for reviewing the design and process changes and assess impact to assure reliability requirements are met.

- Authored operational, maintenance and calibration procedures for production equipment, test equipment, and utilities.

- Validated test methods and analyzed the data using Gage R&R and Anova studies.

Experience

5-7 Years

Level

Executive

Education

Bachelor Of Science

Junior Validation Engineer Resume

Objective : Accomplished Junior Validation Engineer who coordinates communications, information, and highly skilled professionals to meet project goals and evaluate progress while assuring smooth, efficient projects and activities. Experienced strategist successfully managing maintenance, adherence, and improvement of the project quality processes to meet all customer and regulatory requirements. Skilled planner with a sense of urgency to deliver integrated, customer-focused solutions.

Skills : Project Management, Quality Assurance, Regulatory Compliance

Description :

- Assist in the maintenance, repair, commissioning and Qualification of RO and WFI purified water systems.

- Providing Engineering support for existing WFI and RO purified water systems to fix or improve performance.

- Generating Standard Operating Procedures (SOP) and Preventative Maintenance (PM) programs for WFI / RO purified water system Providing engineering and consulting services on project-related issues for clients.

- Write protocols that challenge the critical parameters related to installation, operation, and performance of the related facility, utilities, computer systems, or equipment Develop/review of various validation documentation including URS, FRS, DDS, SOP, IQ, OQ, PQ, Traceably Matrices and Summary Reports.

- Packaging line Pharmaceutical Equipment Validation Performed Computer System Validation on OnBase Software Systems Building Automation System (BAS) Qualification Equipment PLC Setup and verification.

- Walk-in Refrigerators and Freezers Qualification.

- Ensure that all deviations to protocols and/or deviations to acceptance criteria are adequately addressed (documented and reviewed) by the Validation Committee.

Experience

2-5 Years

Level

Junior

Education

Bachelor Of Science

Validation Engineering Support / Lab Manager Resume

Summary : A good team player with good communication, interpersonal skills and an ability to work in challenging deadlines. Good in writing, reviewing and execution of test cases. Attention to detail and strong problem-solving skills are critical. Having the ability to work as a team player and Initiative and the ability to work with minimal guidance.

Skills : 3D Modelling & Analysis Packages: SolidWorks, AutoCAD, CATIA, ANSYS, Minitab, Matlab, 5S, Kaizen

Description :

- Perform commissioning and validation for a new manufacturing facility and author qualification protocols.

- Develop risk assessments, deviation responses, and summary reports for qualification activities.

- Execute equipment validation for facilities, cold rooms, HVAC, CIP, COP, critical utilities and laboratory equipment.

- Executed temperature mapping studies and engineering test plans prior to validation activities.

- Designed experiments and authored protocols, summary documentation, change controls and regulatory documentation.

- Managed deviation and non-conformance reports and investigations. Scheduled project activities in concert with the production schedule while meeting all milestones.

- Implemented and executed qualification procedures for chromatography systems, clean steam, dispensing stations, WFI, HVAC, CIP, SIP, COP, cold storage rooms, fume hoods, floor scales, and critical utilities.

- Performed a variety of general validation activities, including the IQ/OQ/PQ activities for equipment such as agitators/mixers, bench scales, centrifuges, and storage vessels.

Experience

7-10 Years

Level

Senior

Education

Bachelors Of Science

Sr. Validation Engineer Consultant Resume

Summary : Sr. Validation Engineer Consultant with around Four years of work experience in Engineering in the roles of Test Automation supporting areas of client-server Technology, Candi Cloud base applications, IoT Cloud platform and Cisco product lines, leadership abilities, validation and setting up a test environment. Manual, functional, and Automation testing of the end-user device, equipment, hardware, and software application. Expertise in designing and developing test strategy test plans, test case and generating test reports, defect reports and product quality assurance documentation.

Skills : Certified Automation Auditor, Firmware testing, Blackbox testing, Post silicon testing

Description :

- Served as a consultant on various client projects, including validating process control systems, laboratory equipment, and computer software and performing document remediation.

- Developed and executed IQ/OQ protocols for Emerson DeltaV process control systems.

- Documented test methods for automation errors identified during commissioning activities.

- Created, executed, and closed out validation activities for laboratory equipment such as Emax microplate readers, analytical balances, incubators, titrators, viscometers, moisture analyzers, polarimeters, muffle furnaces, ovens, autoclaves, pH meters, refrigerators, HPLCs, GCs, spectrophotometers, Agilent UV-Vis, pipetting machine, dissolution testing station, and interface validation module.

- Drafted SOPs for validated laboratory equipment.

- Facilitated development and implementation of warehouse and order management software systems.

- Assessed validation documents against customer guidelines and made recommendations, as necessary.

- Supported change control and remediation of existing instrumentation validation documents.

Experience

7-10 Years

Level

Senior

Education

Bachelor Of Science

Component Validation Engineer Resume

Objective : Component Validation Engineer with over four years of experience in validation, testing and extensive experience in Computer System Validation (CSV) in compliance with FDA standards. Excellent understanding of the Software Development Lifecycle (SDLC). Hands-on experience with GAMP 5 Guideline, Software Development Life Cycle (SDLC) methodologies, documenting the project and validation deliverables, gathering business, functional and system requirements, developing testing and validation protocols (IQ/OQ/PQ), summarizing reports and final validation packages.

Skills : CSV, Operating Systems Windows 7, 8, 10 Programming Languages Java

Description :

- Review and approves validation documentation, protocols, and reports.

- Provide the execution scope outlined in the validation protocols, including the collection, review, analysis of tests and verification of submitted data and reports.

- Participates in the validation process and protocols execution of existing and new GMP manufacturing equipment, optical tooling instruments, autoclaves, and computerized systems.

- Serve as the subject matter expert (SME) on manufacturing equipment/systems and instrument qualifications and validations non-compliance issues, such as protocol discrepancies/deviations, non-conformance reports (NCR's) and troubleshooting/solving activities.

- Review Engineering Studies as pertains to the qualification of existing and new GMP manufacturing equipment, optical tooling instruments, autoclaves, and computerized systems, as applicable.

- Assess the impact of proposed changes to cGMP related systems.

- Suggest/implement corrective actions/preventive actions as needed to maintain cGMP/FDA regulation and Site policies and procedures.

Experience

2-5 Years

Level

Junior

Education

Bachelor Of Science

System Validation Engineer II Resume

Summary : System Validation Engineer II with a comprehensive record of success in manufacturing engineering and production. Progressive responsibility in supervision, business development, complex project management, and technical design. Proven capability in engineering spanning mechanical design, validation, testing, and production inspection. Demonstrated ability to maintain schedules and finish projects under budget. Extensive knowledge of engineering design standards and lean operation methods.

Skills : Project Management, PCBA Design, Validation Engineering, Test Engineering, System Specification.

Description :

- Provided design, analysis, testing and validation for brake systems, steering and suspension, chassis power train and fuel systems as well as exterior systems.

- Analyzed product design and launched the best method for manufacturing brake system products for prestige and performance vehicles.

- Directed design, development and improvement of manufacturing processes and provided technical support for specific operations.

- Implemented operating procedures, resolved system malfunctions, and provided technical information for staff.

- Coordinated information from internal and external customers to enhance market penetration and customer satisfaction.

- Developed and tested models of alternate designs and processing methods to assess feasibility, operating condition effects, possible new applications and necessity for further changes and modification.

- Maintained current knowledge of product developments and trends and actively identified new areas of information.

- Streamlined processes and contain costs for new equipment associated with the department.

Experience

10+ Years

Level

Consultant

Education

Bachelors Of Science

Quality/ Validation Engineer Resume

Objective : Quality/ Validation Engineer with over 2 years of Information Technology experience with expertise in Computer System Validation (CSV) and Software Development Life cycle (SDLC) in FDA regulated Biotechnology and Pharmaceutical industry. Good working experience in FDA regulated environment with expertise in implementing 21CFR part11 compliance requirements and Annex 11, 21 CFR Part 210 / 211and 820. Experience in developing and reviewing User Requirements Specification (URS) and Functional Requirements Specification (FRS) documents.

Skills : SolidWorks, AutoCAD, CATIA, ANSYS, Minitab, Matlab, 5S, Kaizen, Poka-Yoke, Root Cause Analysis

Description :

- Prepared a Validation Master Plan (VMP) for validating the Trackwise application.

- Involved in the complete system development life cycle and documentation.

- Authored User Requirement Specifications (URS) and Functional Requirement Specifications (FRS) by closely working with Business Analyst.

- Developed and reviewed Standard Operating Procedures (SOPs) for various functionalities of the system Reviewed the Test Strategy document prepared by the testing team and provided input on the validation requirements.

- Involved in creation, execution and responsible for pre and post-execution review of Unit Test scripts, Performance/Automated Test Scripts, Regression Test Scripts, IQ/OQ/PQ Test Scripts and UAT Test Scripts.

- Analyzed test scripts to check whether all functionalities have been covered within the compliance of 21 CFR Part 11 Responsible for Test Case Development, Execution and summarizing the results following strict FDA regulation - 21 CFR Part 11.

- Participated in system test script execution and documented results.

Experience

2-5 Years

Level

Junior

Education

Bachelor Of Science

Data Validation Engineer Resume

Headline : Data Validation Engineer with over five years of experience in validation, testing and extensive experience in Computer System Validation (CSV) in compliance with FDA standards. Excellent understanding of the Software Development Lifecycle (SDLC). Hands-on experience with GAMP 5 Guideline, Software Development Life Cycle (SDLC) methodologies, documenting the project and validation deliverables, gathering business, functional and System requirements, developing testing and validation protocols (IQ/OQ/PQ), summarizing reports and final validation packages.

Skills : Temperature Mapping, Commissioning & Qualification, Project Management, CIP, Sterilization, ASTM E2500/ISPE, Systems, and Equipment.

Description :

- Designed, implemented and validated 21 CFR Part 11 compliance strategies for LIMS.

- Played a major role in performing part 11 assessment, especially contributing to the components involved in the maintenance of Electronic Records (ER), Electronic Signatures (ES) and Audit Trails in accordance with 21 CFR part 11 regulations.

- Provided system support and configuration support required to maintain quality management solution.

- Wrote the technical specifications for new business processes, updated technical specs for improvement and generated validation documentation.

- Authored and reviewed the procedures pertaining to Installation Qualification (IQ), Operational Qualification (OQ) and Performance Qualification protocols for the LIMS application.

- Analyzed User and Functional requirements to develop Test Plans, Test Cases and Test Scripts using HP ALM and executed them.

- Executed validation test cases based on system requirements and FDA standards.

- Performed functionality testing for the entire application.

Experience

5-7 Years

Level

Executive

Education

Bachelor Of Science

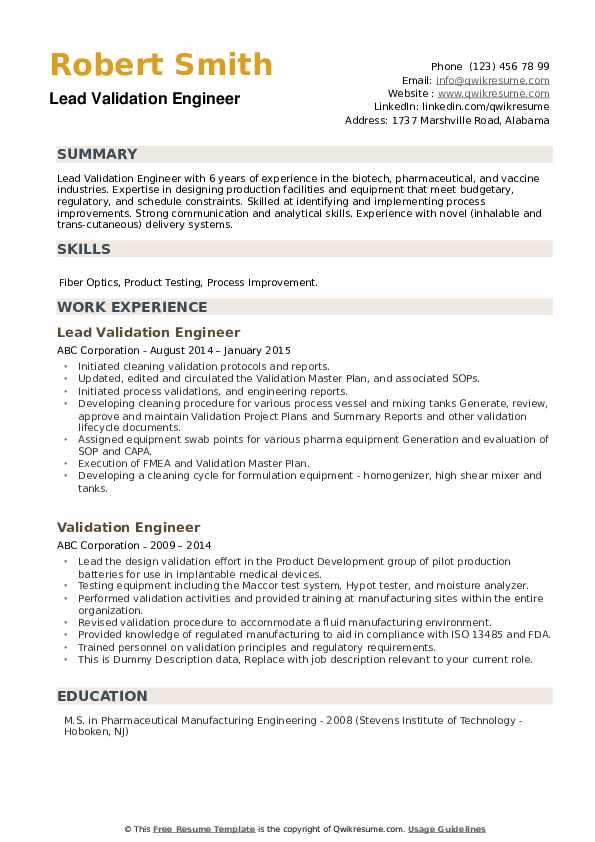

Lead Validation Engineer Resume

Headline : Lead Validation Engineer with 6 years of experience in the biotech, pharmaceutical, and vaccine industries. Expertise in designing production facilities and equipment that meet budgetary, regulatory, and schedule constraints. Skilled at identifying and implementing process improvements. Strong communication and analytical skills. Experience with novel (inhalable and trans-cutaneous) delivery systems.

Skills : Fiber Optics, Product Testing, Process Improvement.

Description :

- Initiated cleaning validation protocols and reports.

- Updated, edited and circulated the Validation Master Plan, and associated SOPs.

- Initiated process validations, and engineering reports.

- Developing cleaning procedure for various process vessel and mixing tanks Generate, review, approve and maintain Validation Project Plans and Summary Reports and other validation lifecycle documents.

- Assigned equipment swab points for various pharma equipment Generation and evaluation of SOP and CAPA.

- Execution of FMEA and Validation Master Plan.

- Developing a cleaning cycle for formulation equipment - homogenizer, high shear mixer and tanks.

- Proficient in determining cleaning MAC (Maximum allowable carryover) limits to establish acceptance criteria for cleaning of equipment Performed Calculation of acceptable residual limits of the Active Ingredients (API) and Detergent.

- Designed, performed the Visual Inspection Test method to determine the acceptance criteria of the cleaning validation protocol of manufacturing equipment.

Experience

5-7 Years

Level

Executive

Education

Masters of Science

Product Validation Engineer Resume

Headline : As a Product Validation Engineer, responsible for performing functional, and compliance testing, working with certification agencies to prove the products to the compliance, coordinating, Mentoring, building, and guiding offshore teams, and also designing, developing, analyzing, and assisting in releasing products and subsystems through product life cycle.

Skills : Organization, Time Management.

Description :

- Applied knowledge of manufacturing processes to support line changes including outsourcing, machining, and assembly.

- Led a cross-functional team (Service, Engineering, Purchasing, and implementation specialists) that resolved product issues and worked with design team to evaluate customer needs and align requirements with customer expectations.

- Influenced department and program using project management techniques and assign work to meet group commitments.

- Led and coached technical/subject matter experts to solve complex technical problems and provide resources to ensure application of common approaches.

- Utilized Value Package Change (VPC) processes and conducts VPCR, participate in cross-functional forums, and use Corporate VPC Notes tool set.

- Completed project work using systems and processes developed to eliminate inefficiencies and roadblocks, utilized Design for Six Sigma (DFSS) including strategical management and growth index to carry out cross-functional design reviews for various work situations and train others in developing and applying reviews.

- Applied 7 Step Product Problem-Solving Process and utilized Fault Tree Analysis to resolve engine product problems, effectively communicated the voice of the customer and the product needs to development teams.

Experience

5-7 Years

Level

Executive

Education

Bachelor's Degree In Computer Science

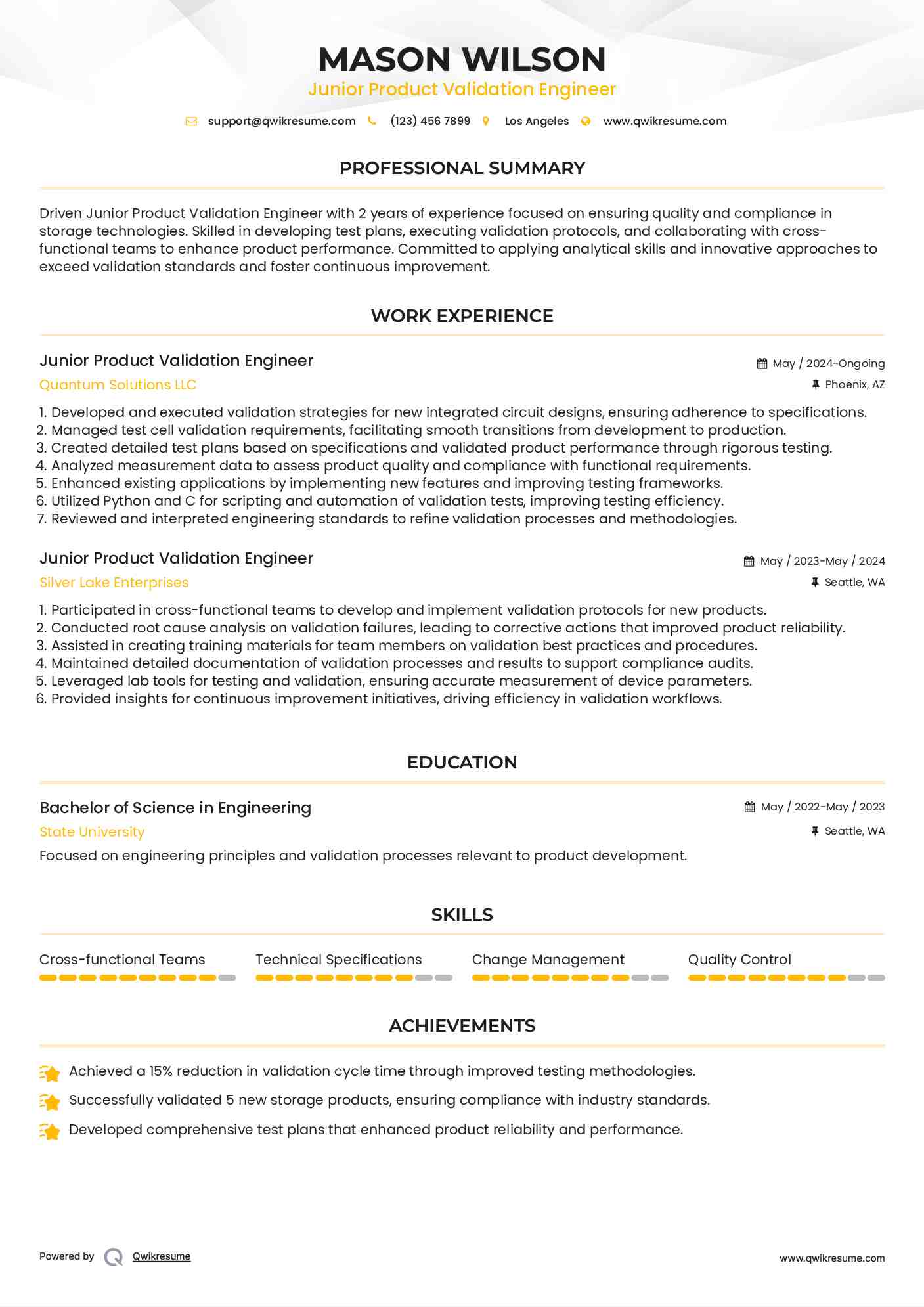

Junior Product Validation Engineer Resume

Objective : As a Junior Product Validation Engineer, experienced in the storage industry, in SSD, HDD, embedded storage systems or related technology, experienced with lab tools: LA, OSC, TRACE, led validation projects for new applications as well as change control of existing applications, and also worked with the core team to outline all product validation and design control deliverables for projects train DNA organization to software validation requirements (Procedures/ Standards/ Best Practices).

Skills : Test Automation, Data Analysis.

Description :

- Validated and characterized new integrated circuit (IC) designs, and developed validation and characterization plans, bench hardware, and software.

- Organized and Managed test cell validation requirements for specific programs, validated and characterized a specific product from tape-out through production and release.

- Compiled, coordinated, and evaluated specification sheets/specifications and planned tests based on them.

- Analyzed measurement data and service strength for hybrid drive components, understood the functional, and non-functional requirements of building automation products, and also developed test strategies, and test cases.

- Updated existing PLSQL/ JAVA applications by expanding its functionality, experienced in Windows, Linux (or macOS ) operating systems, and experienced with typical test systems used in the storage industry.

- Expertised in the use of Python, C, scripting languages, programming tools, and environments, performed bench testing to measure various device parameters in the lab for design verification, characterization, and correlation.

- Evaluated and interpreted Engineering Standards to improve validation and testing components.

Experience

2-5 Years

Level

Junior

Education

Bachelor's Degree In Engineering

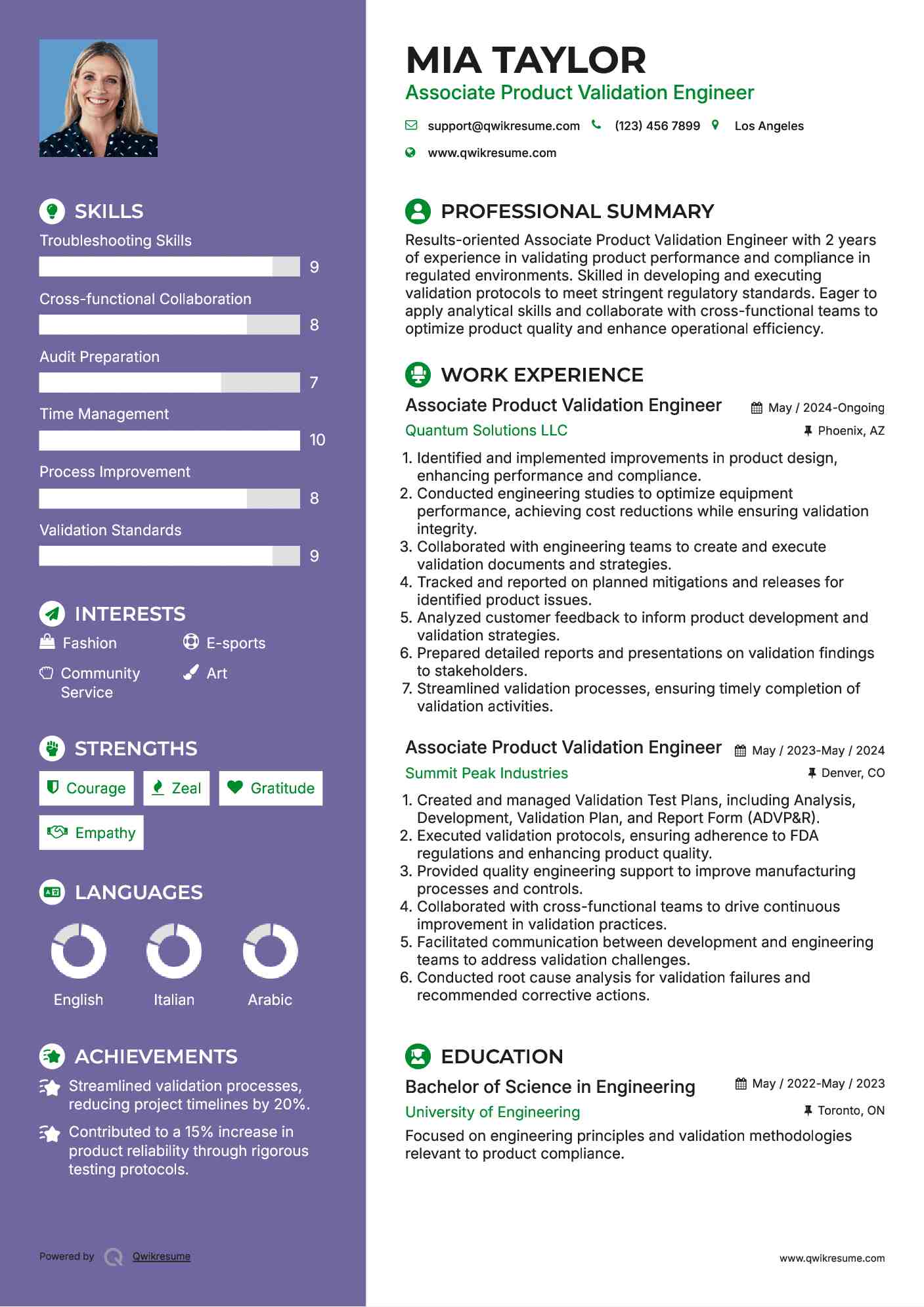

Associate Product Validation Engineer Resume

Objective : As an Associate Product Validation Engineer, responsible for improving work methods by analyzing methods and procedures to ascertain the most efficient way to perform all tasks, and working closely with Engineering to develop, coordinate, and execute Validation documents and strategies.

Skills : Project Management, Communication.

Description :

- Identified opportunities to revise and improve product design or product performance and implemented these improvements.

- Developed and performed engineering studies for improvements in equipment performance or process capabilities to reduce costs and cycles while ensuring validations.

- Developed and performed engineering studies for improvement of equipment performance or process capabilities to reduce costs and cycles while ensuring validations.

- Worked closely with Engineering to develop, coordinate, and execute Validation documents and strategies.

- Worked closely with the Development Team and tracked planned mitigation and releases for identified issues with the Product team.

- Gathered and analyzed customer feedback, and generated reports that show the progress of the initiative.

- Created reports and presentations about product data findings.

Experience

2-5 Years

Level

Executive

Education

Bachelor's Degree In Engineering

Product Validation Engineer Resume

Objective : As a Product Validation Engineer, responsible for continuously driving improvement in validation methods, tools, UX, cycle time, and content optimization, identifying and recommending corrective actions to observed test issues, and also participating in teams designing, building, and implementing new actuation test lab equipment, software and data collection equipment.

Skills : Validation Engineer, Implementational Skills.

Description :

- Worked directly with Applications Engineers and Technicians to ensure timely participation in teams designing, building, and implementing new actuation test lab BSEE with at least 4 years of industry experience.

- Developed protocols using engineering experience and statistical process controls for new products and equipment that thoroughly test failure modes in order to ensure robust operation during production.

- Assisted with multiple cross-functional projects from development through release to production.

- Facilitated startup, packaging line FAT and qualifications, and new product launch.

- Coordinated activities in support of the Validation Department priorities with the assistance of the department manager.

- Experienced in a Technical/ QA/ Validation Role within the pharmaceutical industry or a similar operating environment with in-depth knowledge of validation processes.

- Coordinated and executed complex DVP and PVP test plans, and worked directly with Applications Engineers and Technicians to ensure timely and accurate test results.

Experience

2-5 Years

Level

Executive

Education

Bachelor's Degree In Computer Science